Abrasive sheet for super precision polishing

An ultra-precise, diaphragm technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve problems such as large environmental pollution, low efficiency, and poor grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

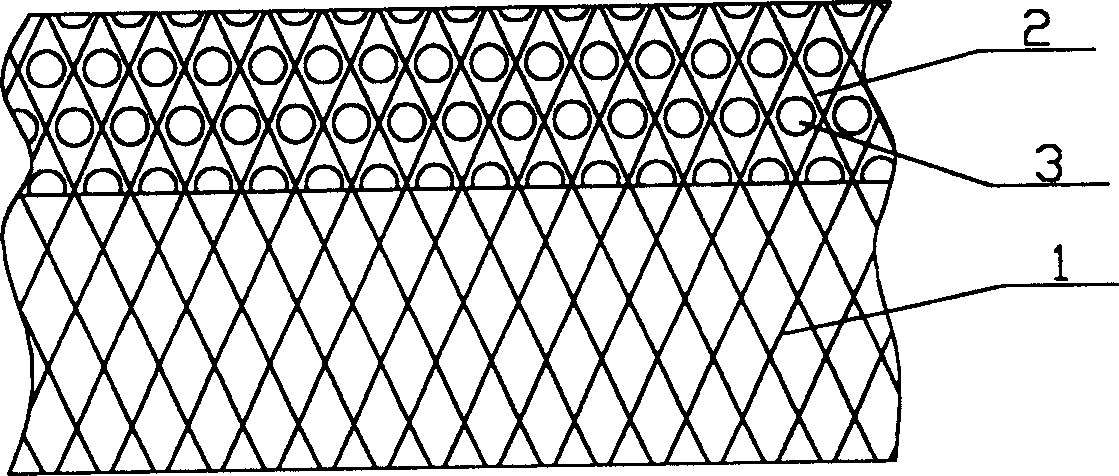

[0005] Specific embodiment one: the ultra-precision grinding diaphragm of the present embodiment is a laminar structure, and the bottom film layer 1 and the abrasive material layer 2 of the soft matrix are followed successively along the thickness direction of the diaphragm, and there are evenly fixed particles in the abrasive material layer 2. The abrasive material 3, the bottom film layer 1 and the abrasive material layer 2 are all made of resin material, and the resin is polyimide or polyamide-6 (PA-6). The abrasive 3 in the abrasive layer 2 is synthetic diamond (JR) abrasive, cubic boron nitride (CBN) abrasive, oxide (WA) abrasive or carbide (GC) abrasive. The particle size number of the abrasive material 3 is 18000-400, and the abrasive material concentration in the grinding layer is 50-200. The bottom film layer 1 of the ultra-precision grinding diaphragm of the present invention is made of a resin material with good temperature resistance and high tensile strength, and ...

specific Embodiment approach 2

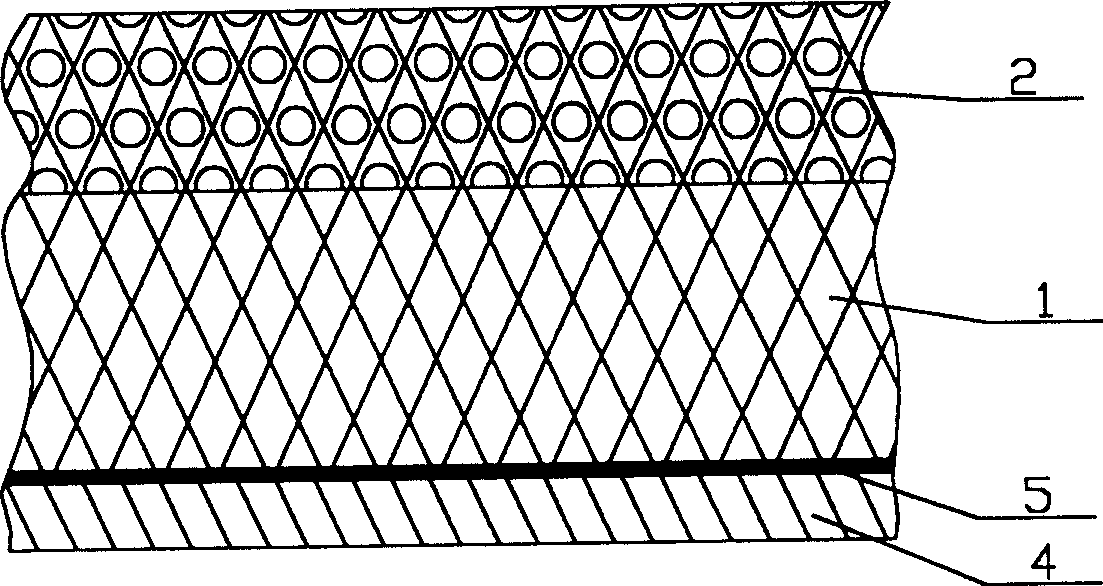

[0006] Embodiment 2: The difference between this embodiment and Embodiment 1 is that there is a protective film layer 4 under the bottom film layer 1 , and the protective film layer 4 and the bottom film layer 1 are bonded together through the self-adhesive layer 5 . Its purpose is to facilitate the pasting of the membrane.

specific Embodiment approach 3

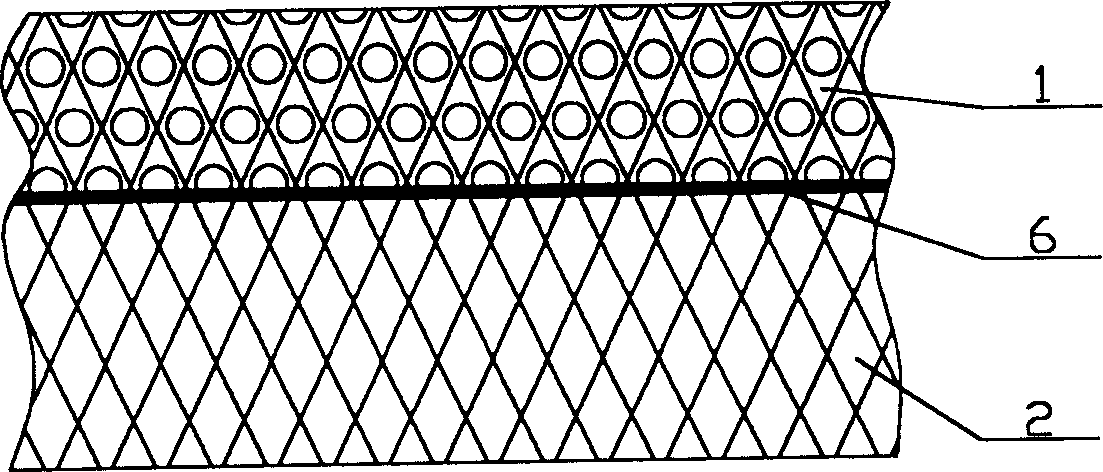

[0007] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the bottom film layer 1 and the abrasive material layer 2 are respectively processed into a two-body structure, and the bottom film layer 1 and the abrasive material layer 2 are covered with another self-adhesive layer 6 glued together. The above-mentioned bottom film layer 1 and abrasive material layer 2 can be processed by casting method or hanging film method respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com