Method for improving isometric property of sand surface of sand planting process and sand planting method

A contour and sand planting technology, applied in the field of high precision, can solve the problems of reduced service life of abrasive cloth, inability to fully guarantee the contour of the sand surface, and contamination of workpieces, so as to reduce consumption, avoid pollution of processed workpieces, and ensure utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

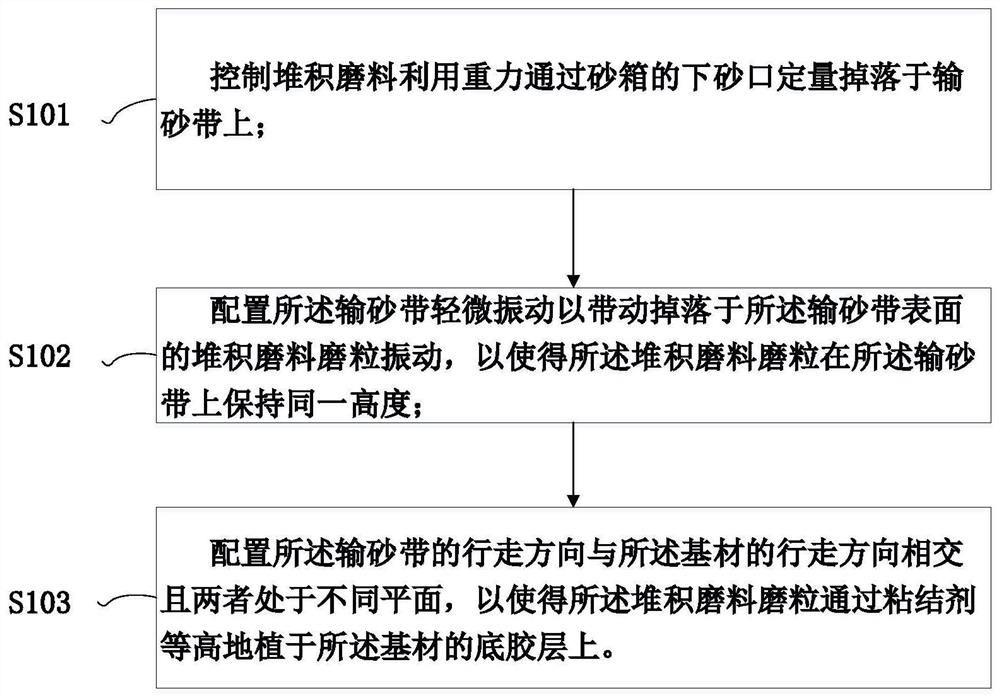

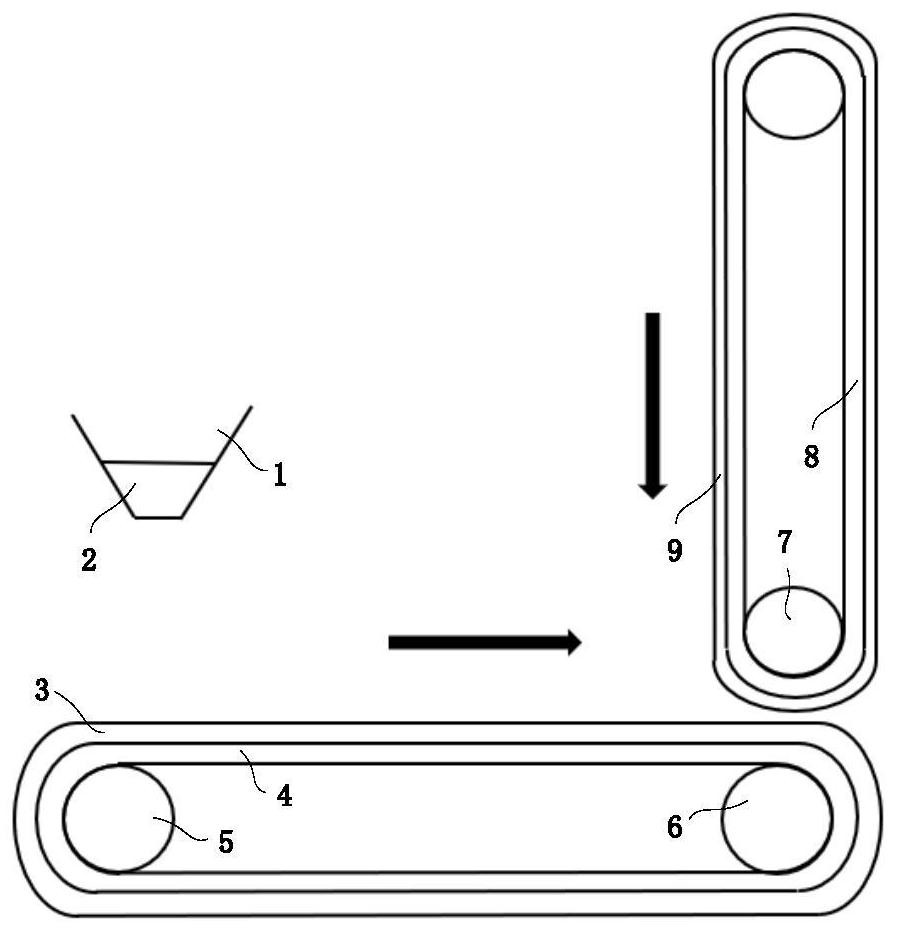

[0035] The invention provides a method for improving the contour of the sand surface in the sand planting process. The vibration of the sand conveying belt ensures that the upper layer of abrasive grains on the sand conveying belt remains on the same level under the action of gravity and vibration force, and the sand planting moment The primer faces downward, and the abrasive adheres to the substrate by controlling the gap between the primer surface and the abrasive belt, so as to ensure that the abrasive is arranged in a single layer on the substrate (single-layer sand planting) and has equal height. Specifically, the following steps are included, such as figure 1 Shown:

[0036] S101: Control the accumulation of abrasives and use gravity to fall quantitatively on the sand conveyor belt through the lower sand port of the sand box; As a result, the accumulated abrasive 2 will fall on the abrasive belt 3. The abrasive is a large-grain accumulation abrasive prepared from ordin...

Embodiment 2

[0050] The present invention also relates to a novel sand planting method suitable for controlling the contour of the sand surface of the accumulated abrasive cloth, comprising the following steps:

[0051] S201: Unroll 8 large rolls of substrate;

[0052] S202: Apply a primer on the front side of the substrate 8 to form a primer layer 9, implant abrasives on the primer layer according to the method of improving the contour of the sand surface of the sand planting process as in Example 1, and then perform pre-treatment. dry;

[0053] S203: coating the pre-dried sand planting surface with a compound compound, and performing main drying;

[0054] S204: Perform curing, parking, flexing and humidifying operations to obtain a final emery cloth product. It should be understood that the storage time of the abrasive cloth prepared by the present invention is 2 days longer than that of the non-accumulating abrasive cloth before flexing, and the flexing is completed, and the large vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com