Humidifying concrete and preparation method thereof

A concrete and aggregate technology, applied in the field of humidity-adjusting concrete and its preparation, can solve the problems of easy saturation and small moisture absorption, and achieve the effect of improving the humidity-regulating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

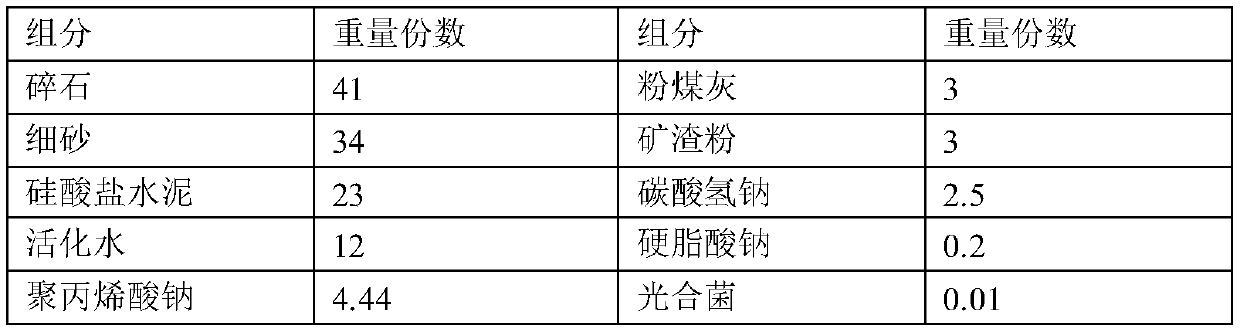

[0035] Embodiment 1 is a kind of humidity-conditioning concrete disclosed by the present invention and its preparation method. The humidity-conditioning concrete comprises the following components by weight:

[0036]

[0037]

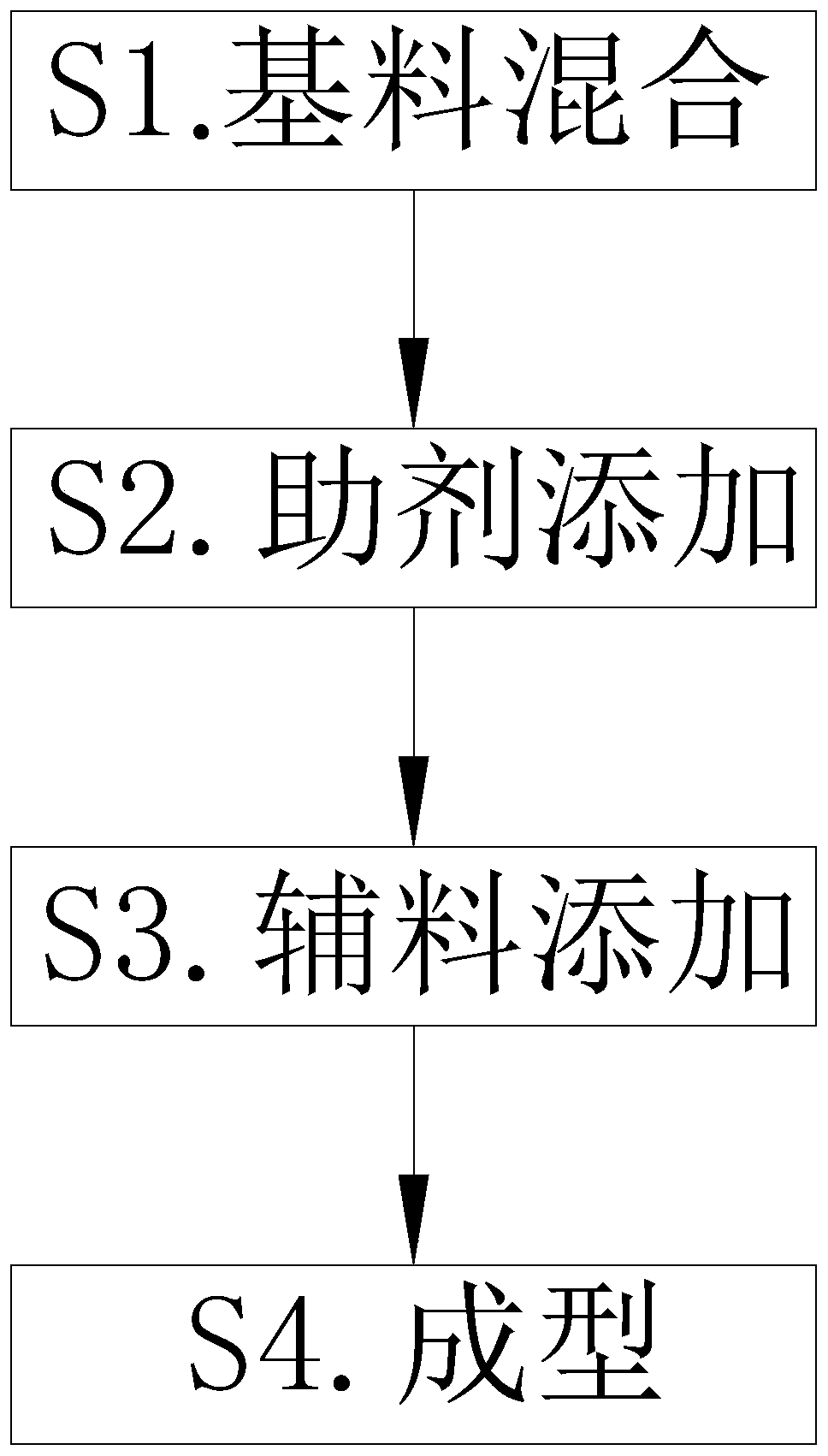

[0038] The preparation method of moisture-conditioning concrete specifically comprises the following steps:

[0039] S1. Base material mixing: Fully mix the aggregate, admixture and Portland cement at a stirring temperature of 30°C to make a mixture;

[0040] S2. Addition of additives: Add activated water and water reducer to the mixture and stir thoroughly. The stirring temperature is 35°C and the stirring time is 3 minutes;

[0041] S3. Addition of auxiliary materials: Add humidity-adjusting material, sodium stearate, photosynthetic bacteria and sodium bicarbonate in sequence and continue to stir. The time interval between each addition is 2 minutes, and the stirring temperature is 40°C. After the addition, stir for 10 minutes to prepare concret...

Embodiment 2

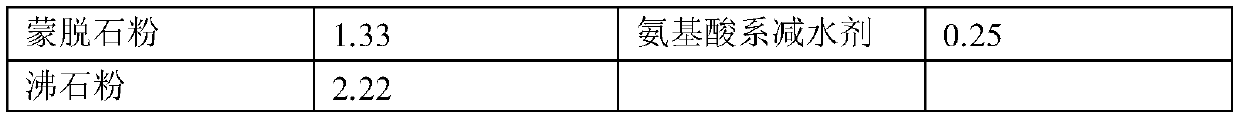

[0043] Embodiment 2 is a kind of humidity-conditioning concrete and its preparation method disclosed by the present invention, the humidity-conditioning concrete comprises the following components by weight:

[0044] components parts by weight components parts by weight gravel 36 fly ash 1.6 fine sand 29 Slag powder 2.4 Portland cement 15 sodium bicarbonate 1 activated water 8 sodium stearate 0.1 Sodium polyacrylate 4.44 photosynthetic bacteria 0.001 Montmorillonite powder 1.33 Amino acid superplasticizer 0.1 Zeolite powder 2.22

[0045] The preparation method of humidity-adjusting concrete is the same as embodiment.

Embodiment 3

[0046] Embodiment 3 is a kind of humidity-conditioning concrete disclosed by the present invention and its preparation method, the humidity-conditioning concrete comprises the following components by weight:

[0047] components parts by weight components parts by weight gravel 47 fly ash 3.2 fine sand 38 Slag powder 4.8 Portland cement 30 sodium bicarbonate 5 activated water 16 sodium stearate 0.3 Sodium polyacrylate 4.44 photosynthetic bacteria 0.015 Montmorillonite powder 1.33 Amino acid superplasticizer 0.4 Zeolite powder 2.22

[0048] The preparation method of humidity-adjusting concrete is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com