Production device of farmland irrigation energy water

A technology for manufacturing devices and farmland irrigation, applied in the field of agricultural irrigation, can solve the problems of easy soil compaction, poor irrigation effect, poor irrigation water quality, etc., and achieve the effects of high dissolved oxygen, strong permeability, and soft soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

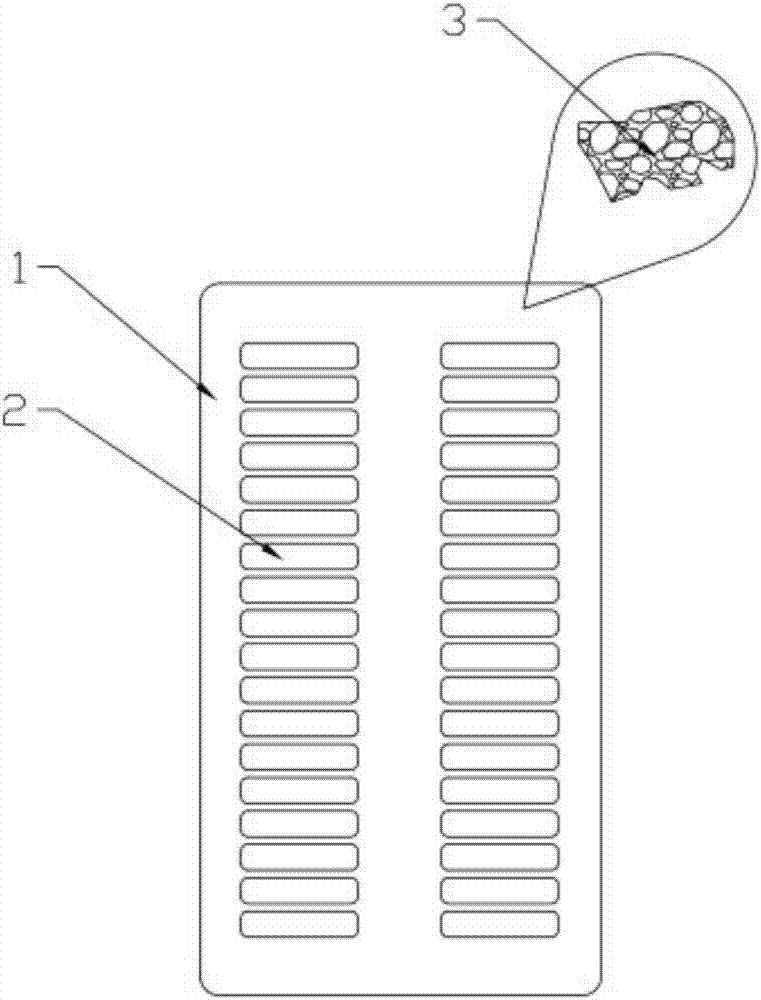

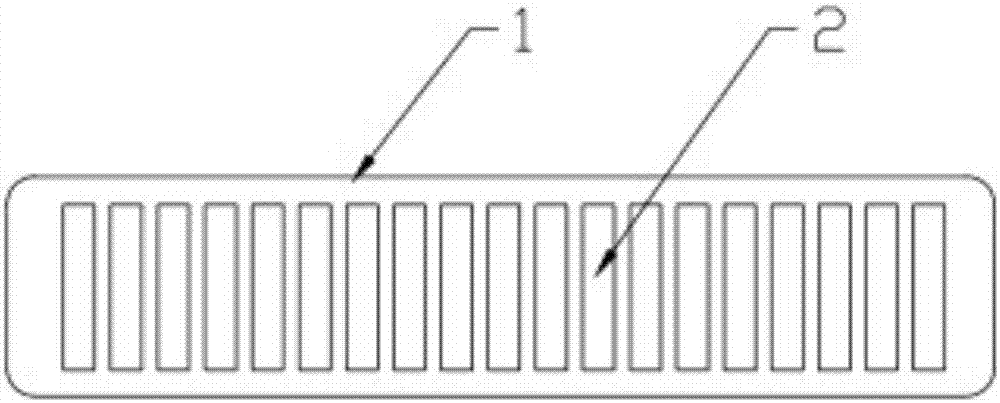

[0025] see Figure 1~2 , the farmland irrigation energy water manufacturing device includes a water-resistant shell 1, a water cluster splitting energy unit is arranged inside the water-resistant shell 1, and the water cluster splitting energy unit decomposes the water of large molecular groups into small molecular clusters of active water, activating water body molecules , to achieve the effect of improving water quality, increasing water energy and making it easy for crops to absorb. By adjusting the composition and structure of the water body, good water quality treatment is done before entering the crop body. Quantum high-tech is used to transform irrigation water into quantum negative hydrogen small molecule active water, which has weak alkalinity, strong permeability, strong diffusion, strong metabolism, high dissolved oxygen, antibacterial and antiviral effects, and soil improvement. Each surface of the water-resistant shell 1 is provided with a plurality of flow holes...

Embodiment 2

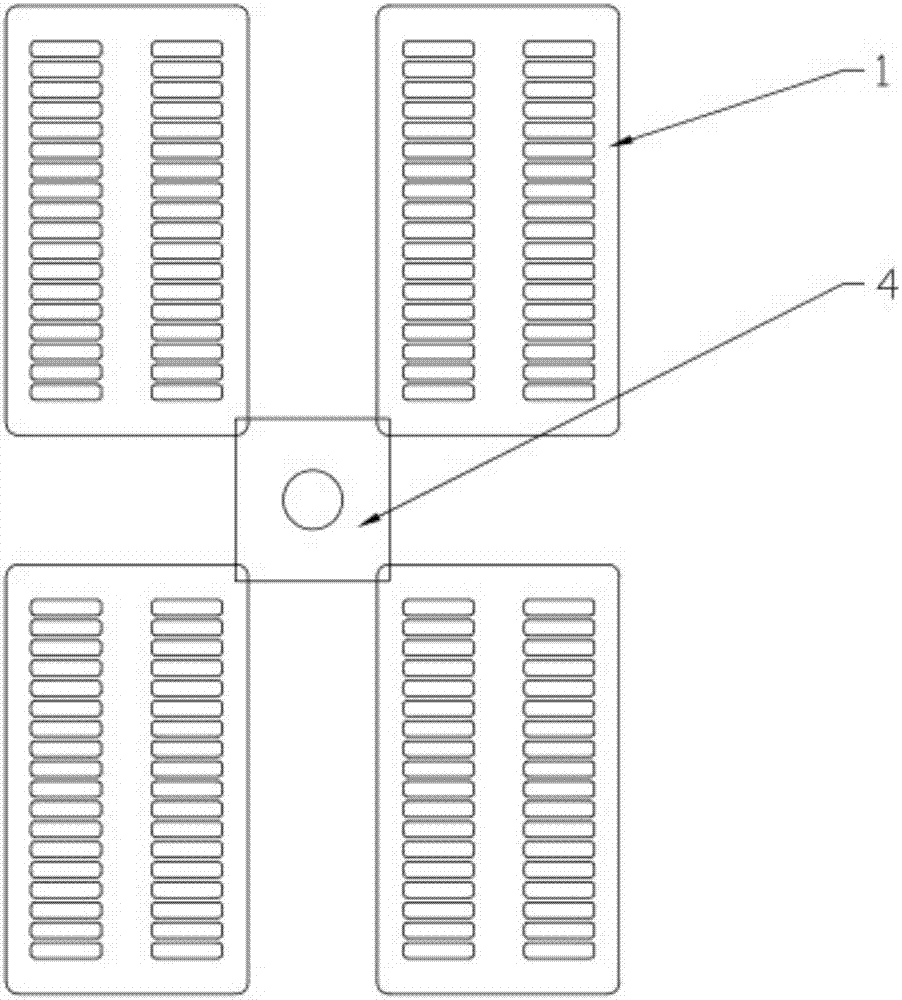

[0029] see image 3 In the present invention, there are multiple water-resistant casings 1 of the farmland irrigation energy water manufacturing device, and four adjacent water-resistant casings 1 are arranged in a square shape and connected into a group through the connecting part 4, which is convenient for transportation. The specific structure of the connecting part 4 An appropriate structure is adopted as required, which will not be repeated here.

Embodiment 3

[0031] see Figure 4 , the nutrient element body in this embodiment is a natural mineral stone sphere 5 placed in the water-resistant shell 1, and the diameter of the natural mineral stone sphere 5 is greater than the diameter or degree of the flow hole 2. The natural mineral stone sphere 5 is made of natural stone rich in nutrients needed by plants to be irrigated. The water cluster splitting energy unit is implanted in the natural mineral stone sphere 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com