Sealing structure of heat core box water-cooling shoot plate

A technology of sealing structure and hot core box, applied in the direction of core, casting molding equipment, casting mold, etc., can solve the problems of cooling water seepage, water leakage, adhesive variability failure, etc., to prevent solidification and prevent water leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

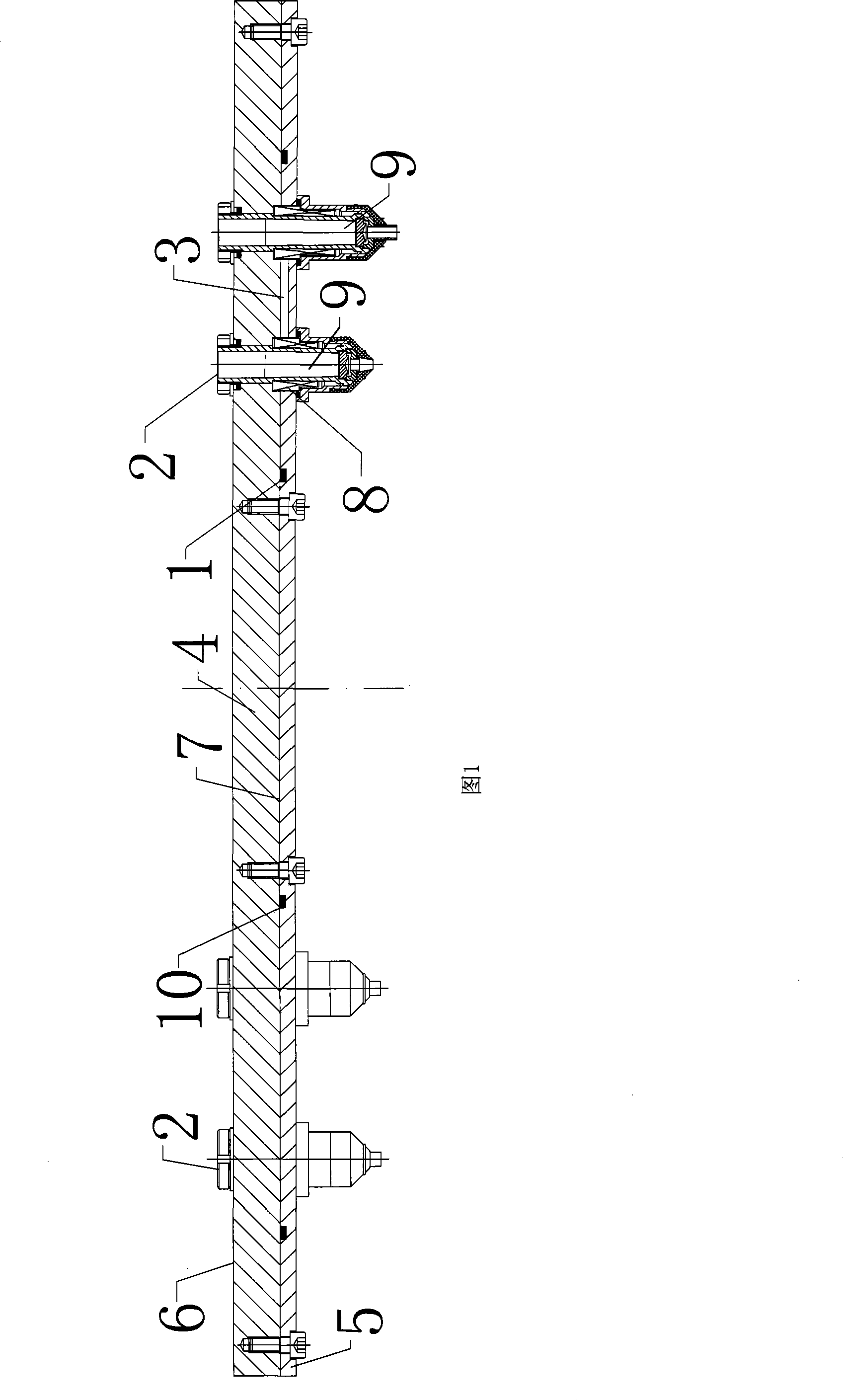

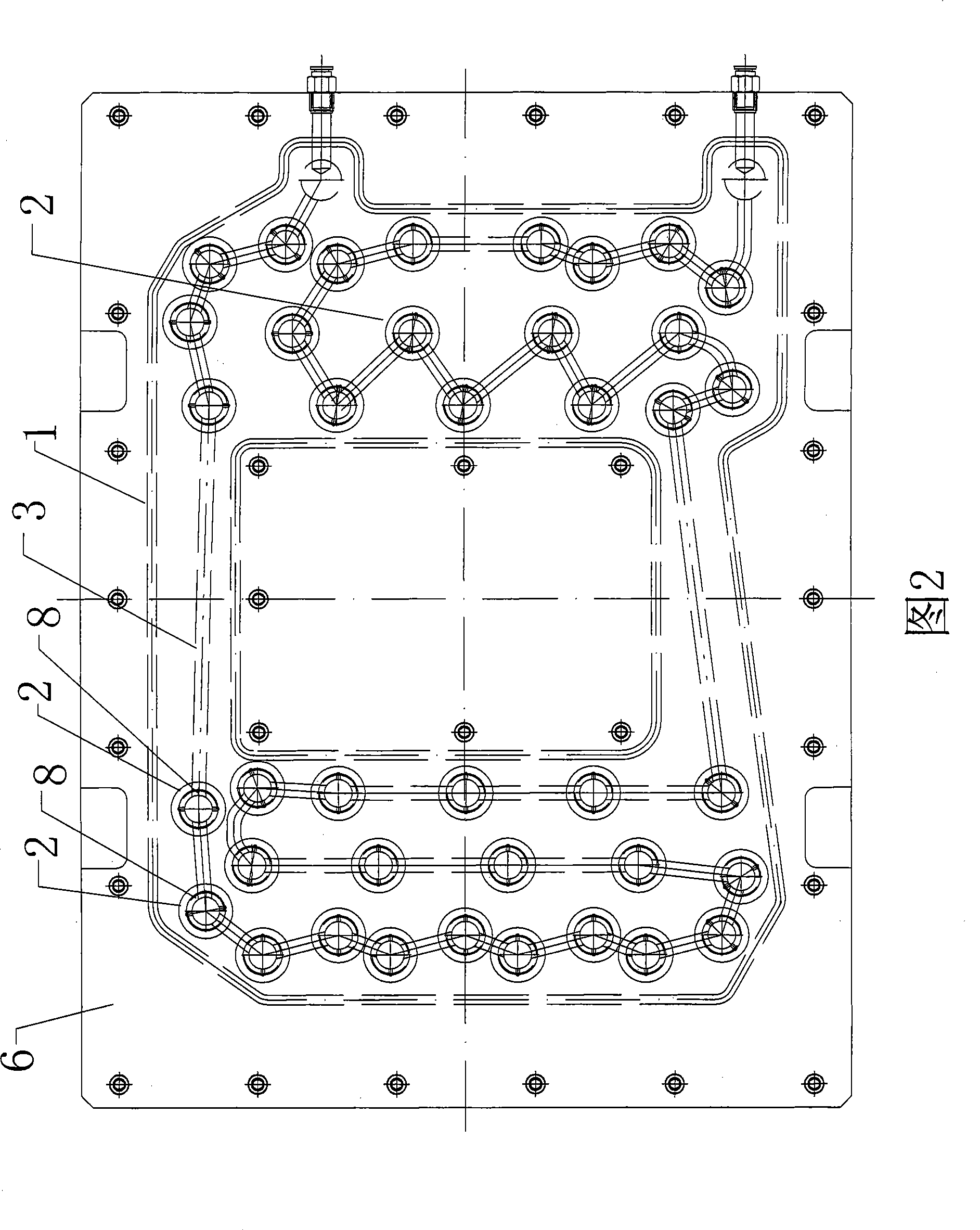

[0009] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] As shown in attached drawings 1-2, a sealing structure of a hot core box water-cooled shooting plate includes a shooting plate 6 and a plurality of nozzles 2 mounted on the shooting plate 6, and the shooting plate 6 is combined by upper and lower plates It is formed and fixed by screws. There are water flow channels 3 that flow through each nozzle in sequence on the joint surface 7 of the upper and lower plates. Specifically, in Fig. 1, the water flow channels 3 are opened on the lower plate 5 and combined with the upper plate. On the upper plate, an annular cooling water channel 8 is opened in each nozzle 2 along its circumference, surrounding the sand-shooting channel 9 in the nozzle 2, for cooling the core sand in the nozzle 2 and preventing the core sand from solidifying , block the sand shooting channel 9, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com