Method for preparing biodiesel

A biodiesel and manufacturing method technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of increasing the difficulty of production operations, long production time, complicated processes, etc., to meet the production needs of normal temperature and pressure, The effect of low cost of production equipment and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

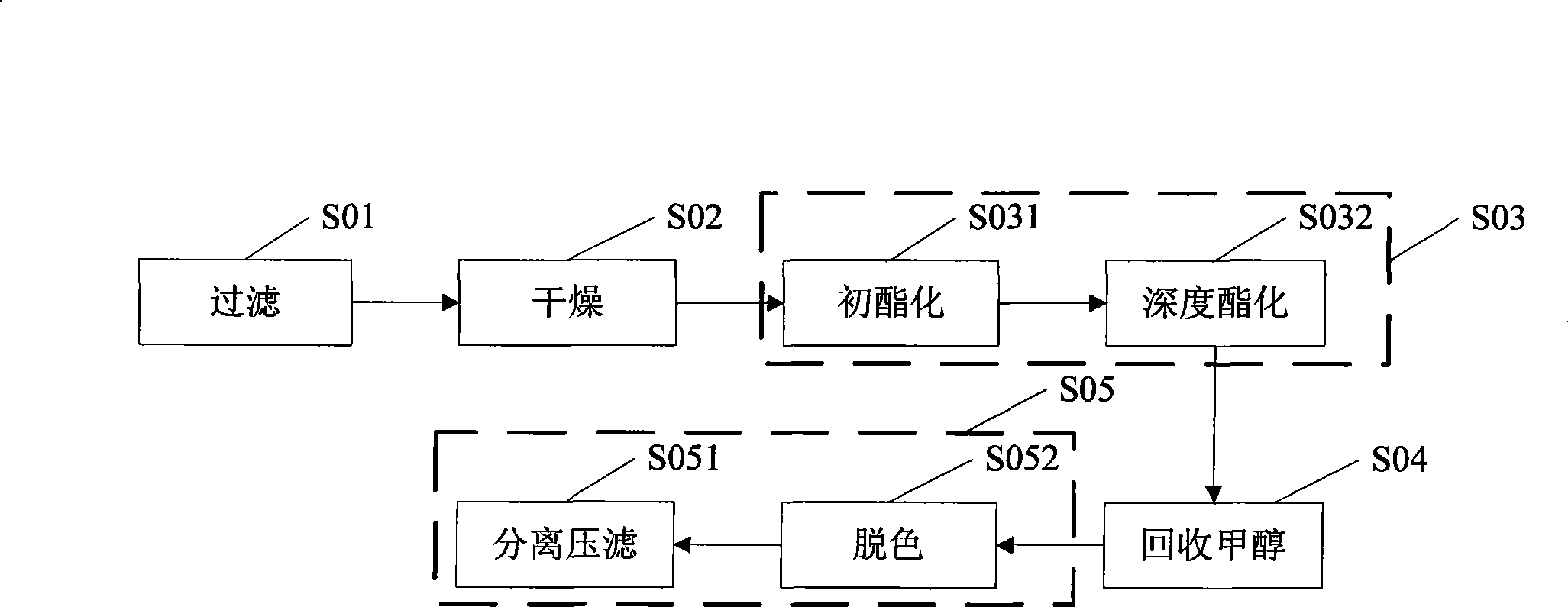

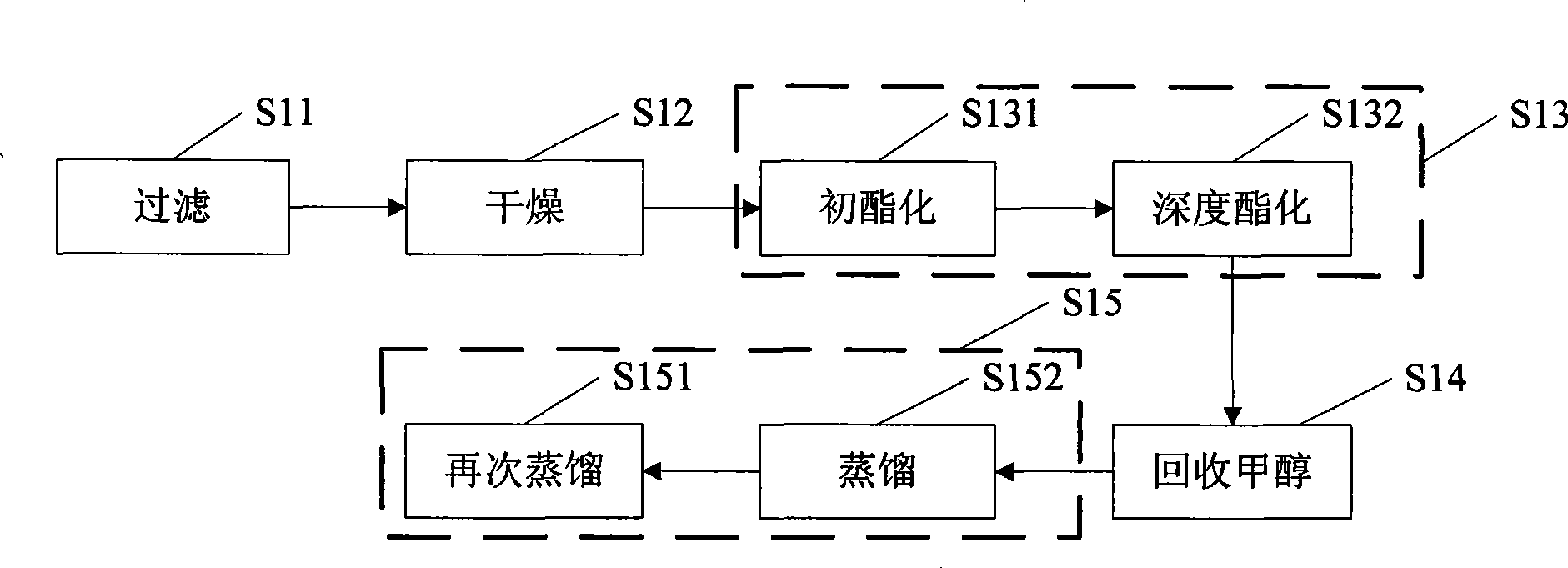

[0016] refer to figure 1 , which is a method flow chart of the first embodiment of the biodiesel manufacturing method provided by the present invention. As shown in the figure, the primary process of the biodiesel manufacturing method in this embodiment specifically includes:

[0017] In the filtering step S01, the preliminary filtered raw oil is heated to 60° C. to 70° C. to make it flowable, and the filter residue of the raw oil is removed through a 40-mesh screen.

[0018] In the dehydration step S02, the raw material oil from which the filter residue has been removed is pumped into a drying and dehydrating tank, heated to 90°C-100°C, stirred at a speed of 30 rpm, and vacuum-dried under a negative pressure of -0.095 MPa to remove the raw material Moisture in the oil, and precipitate to remove a small amount of impurities at the bottom of the cone.

[0019] The esterification reaction is to promote the reaction to the positive reaction direction of fatty acid methyl ester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com