Mine laneway disaster prevention water wall

A water wall and roadway technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of high risk, huge material consumption, air leakage, etc., and achieve rapid construction of closed walls, simple overall structure, and simple operation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

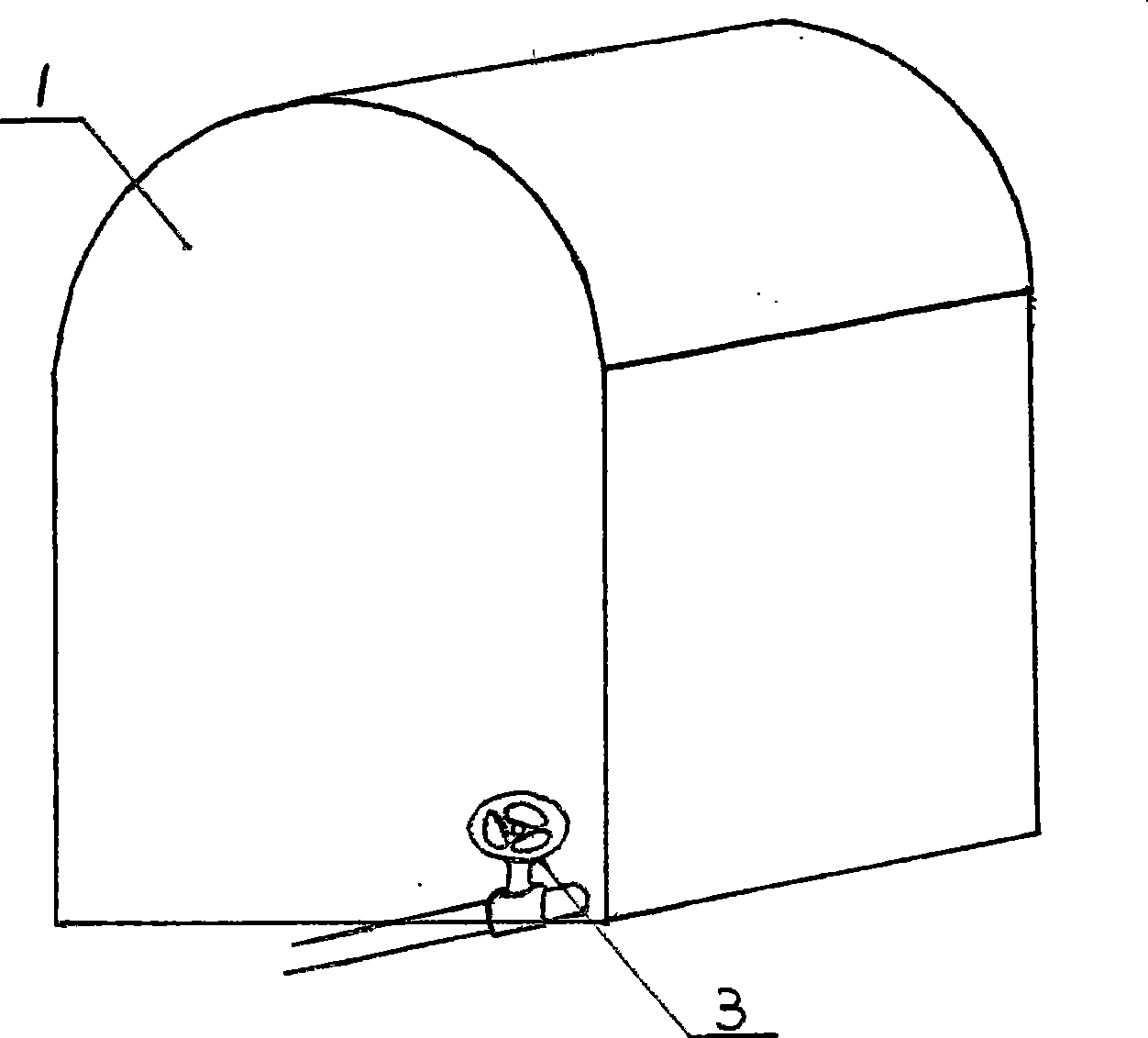

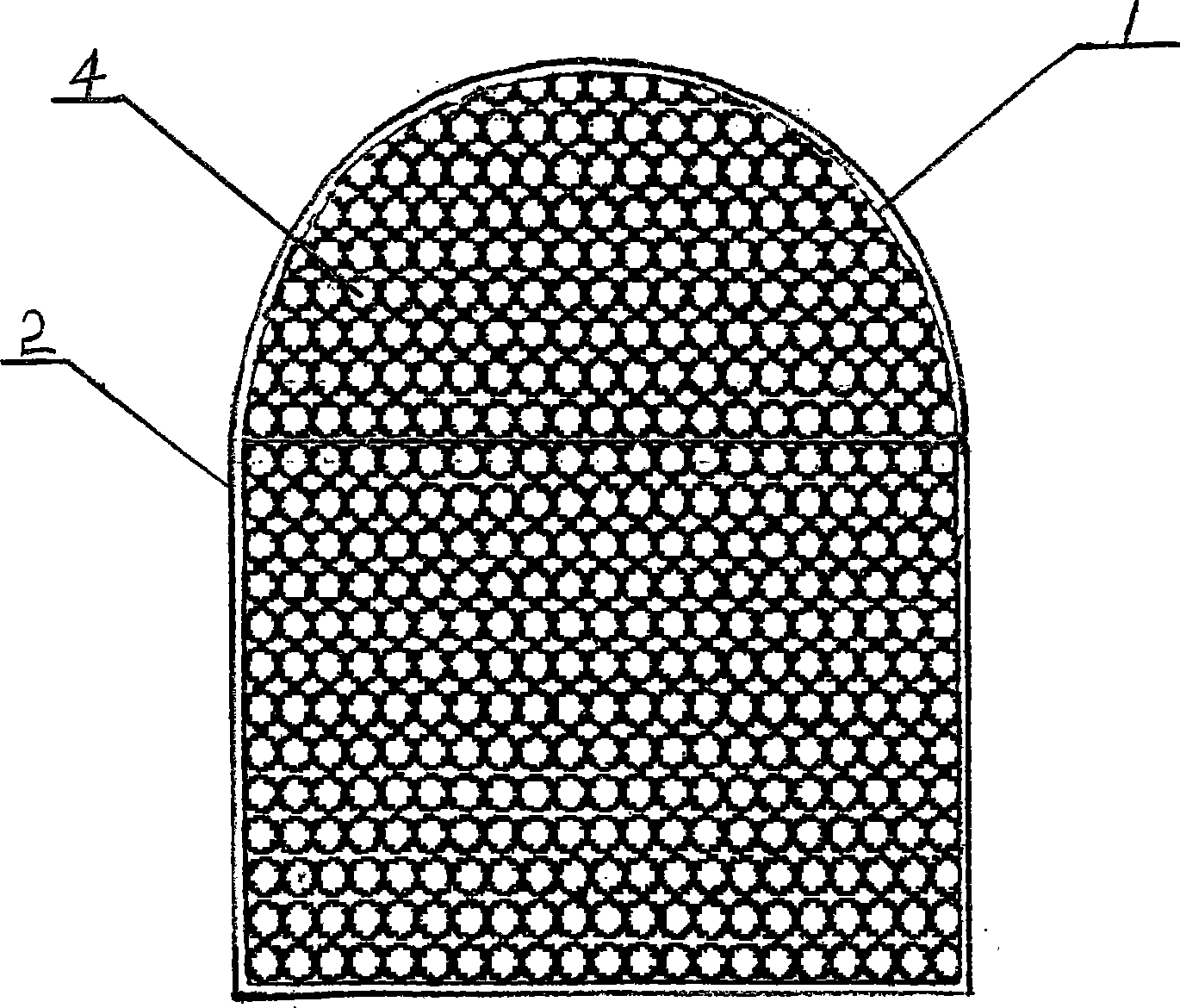

[0013] Referring to the accompanying drawings as follows: mine roadway disaster prevention water wall, including water wall body (1), fireproof cloth (2), pressure valve (3), it is characterized in that the water wall body (1) is polyurethane lining fire hose (4) The spliced multi-airbag structure, the surface is made of flexible plastic cloth made of high-strength nylon as the base cloth, and the fireproof cloth (2) covering the surface of the body (1) is made of light materials with low thermal conductivity. The first layer is a heat-resistant airtight layer, and the outer layer is a flame-retardant and fire-resistant layer coated with conductive stripes, which can effectively prevent fire and static electricity. When a disaster occurs, it is only necessary to start the automatic inflation system of the water wall, and the water wall will expand rapidly and be filled with water, and then fix it with a pressure valve (3), so that a complete water wall can close the roadway t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com