Electric excitation planet reduced speed type engine starting machine for vehicle

A technology of planetary reducer and planetary deceleration, which is applied in the direction of engine motor starting, engine starting, engine components, etc., and can solve problems such as difficulty in starting high-power engines, shortening the life of starter motors, and small starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

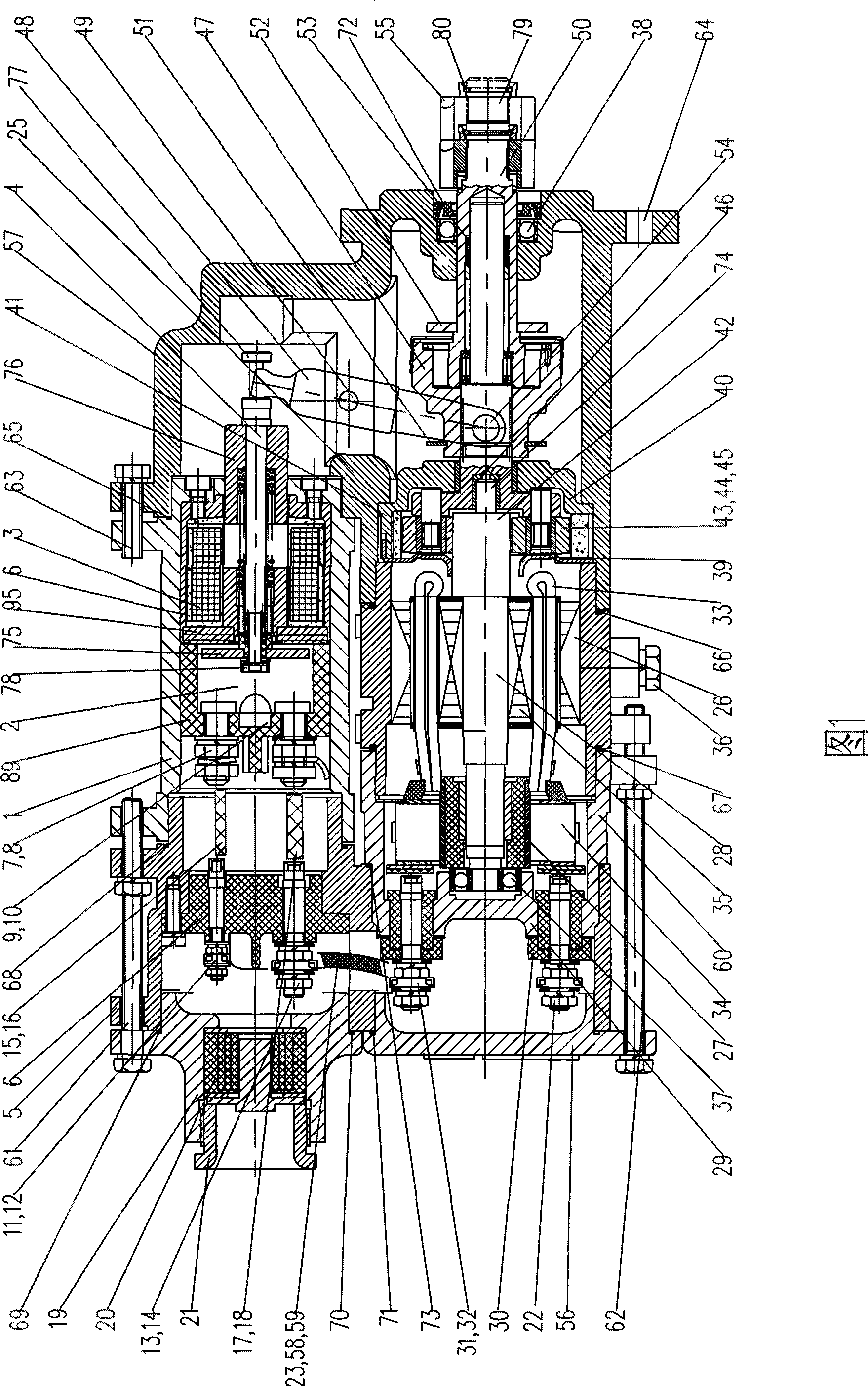

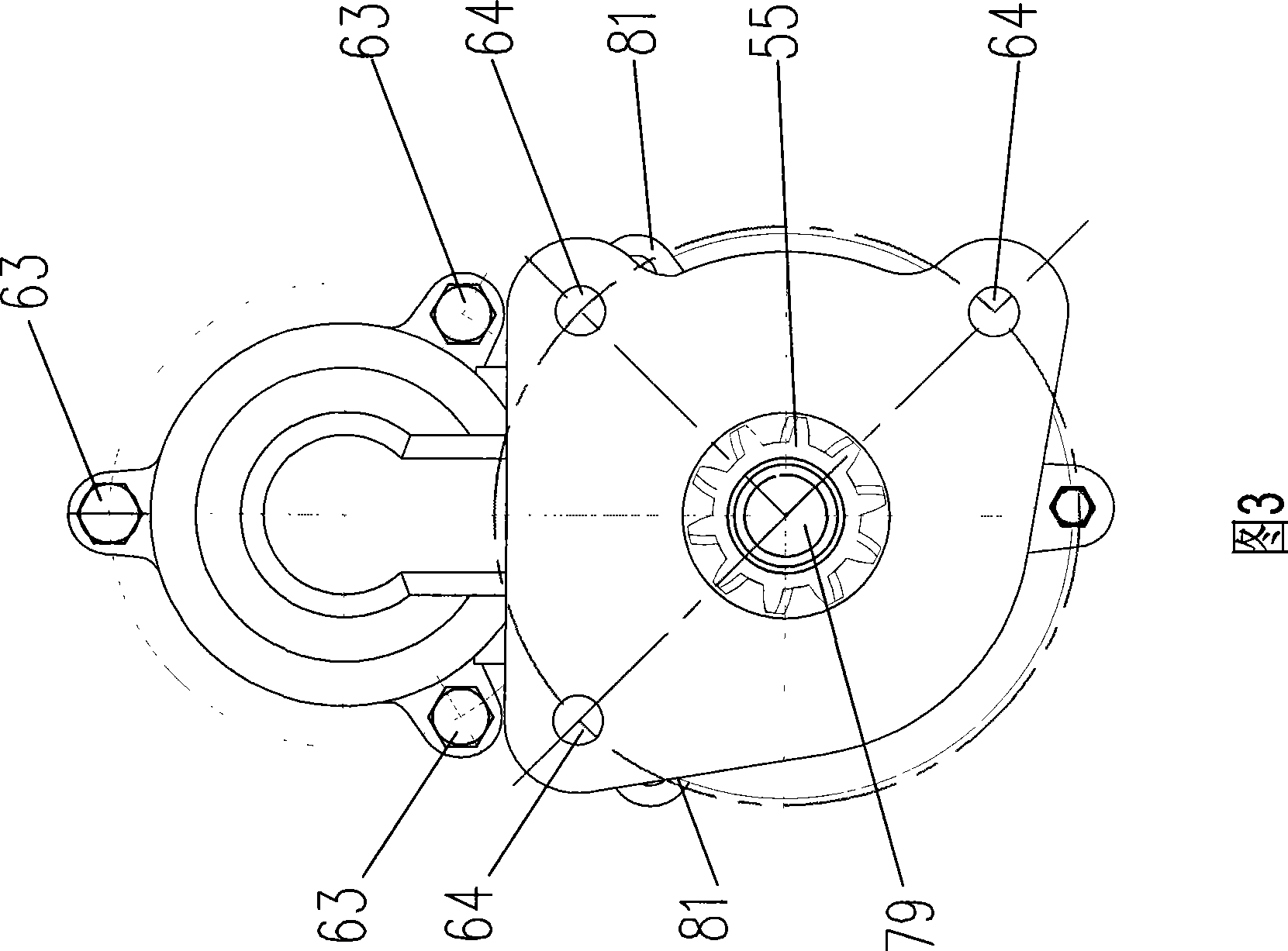

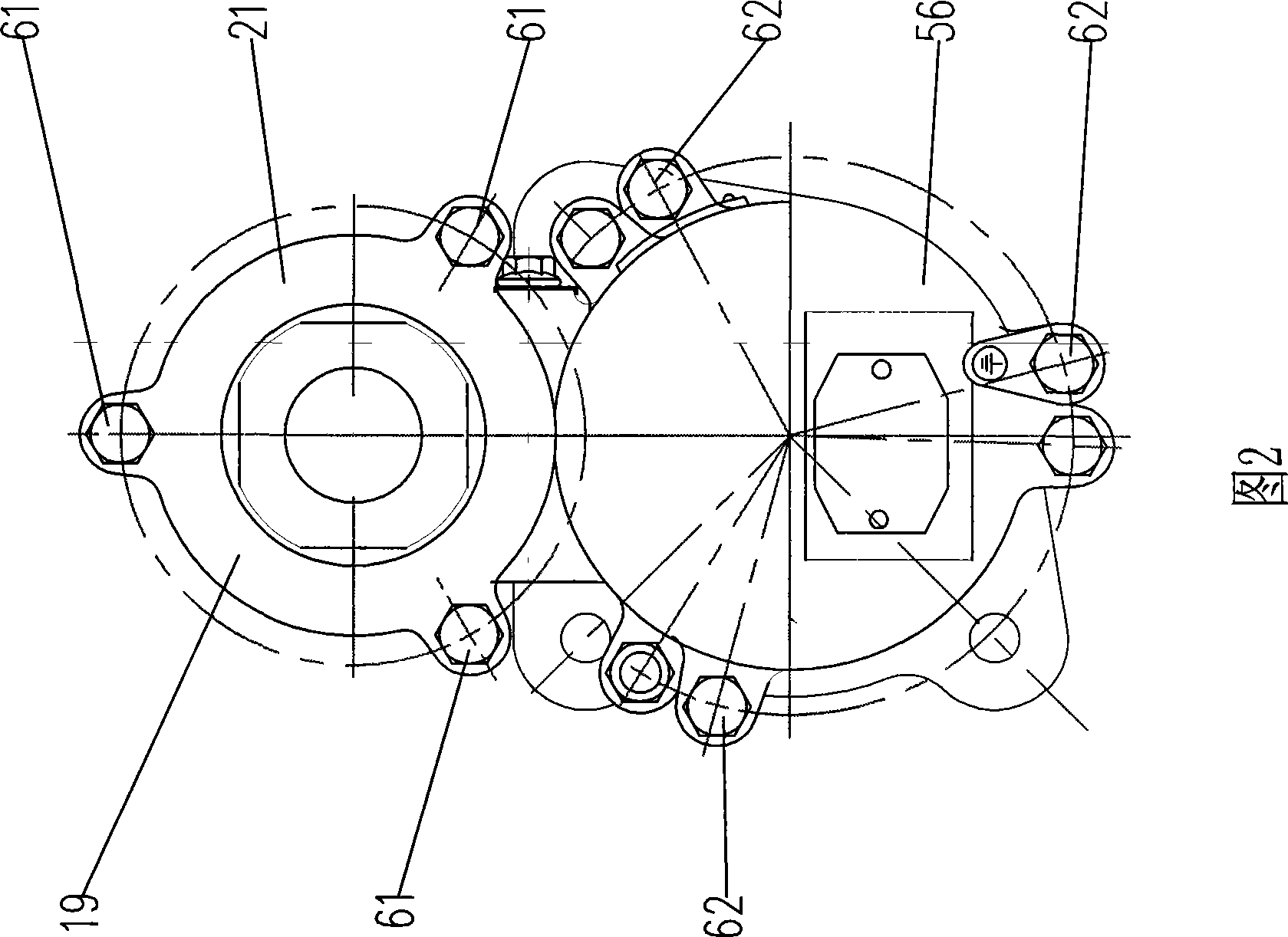

[0031] As shown in Figure 1, 2 and 3, it is the overall structure diagram of the starter, which is rectangular as a whole, and mainly consists of an electric excitation mechanism, a DC motor, a planetary reducer, a shift fork mechanism, a driving mechanism, an output mechanism, a terminal post, a magnet junction box, Composed of flameproof protection end cover.

[0032] The 24V DC motor is connected to the terminals 11, 12, 13 and 14, and the electromagnet 3 generates a magnetic field to form an electric excitation effect; the terminals 12, 13 and 14 are connected to the terminals 22, 31 and 32 of the 24V DC motor at the same time to form a unified Voltage synchronous start; DC motor 26 rotates after being connected to 24V current, no-load current ≤ 110A, no-load speed ≥ 4200rpm; starter braking performance: voltage ≤ 11V, current ≤ 900A, torque ≥ 80Nm, through the motor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com