Improved fan bearing set structure

A technology of fan bearing and group structure, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problems of vibration and noise, waste, high production cost, and prevent Effects of noise and wear, increased service life, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

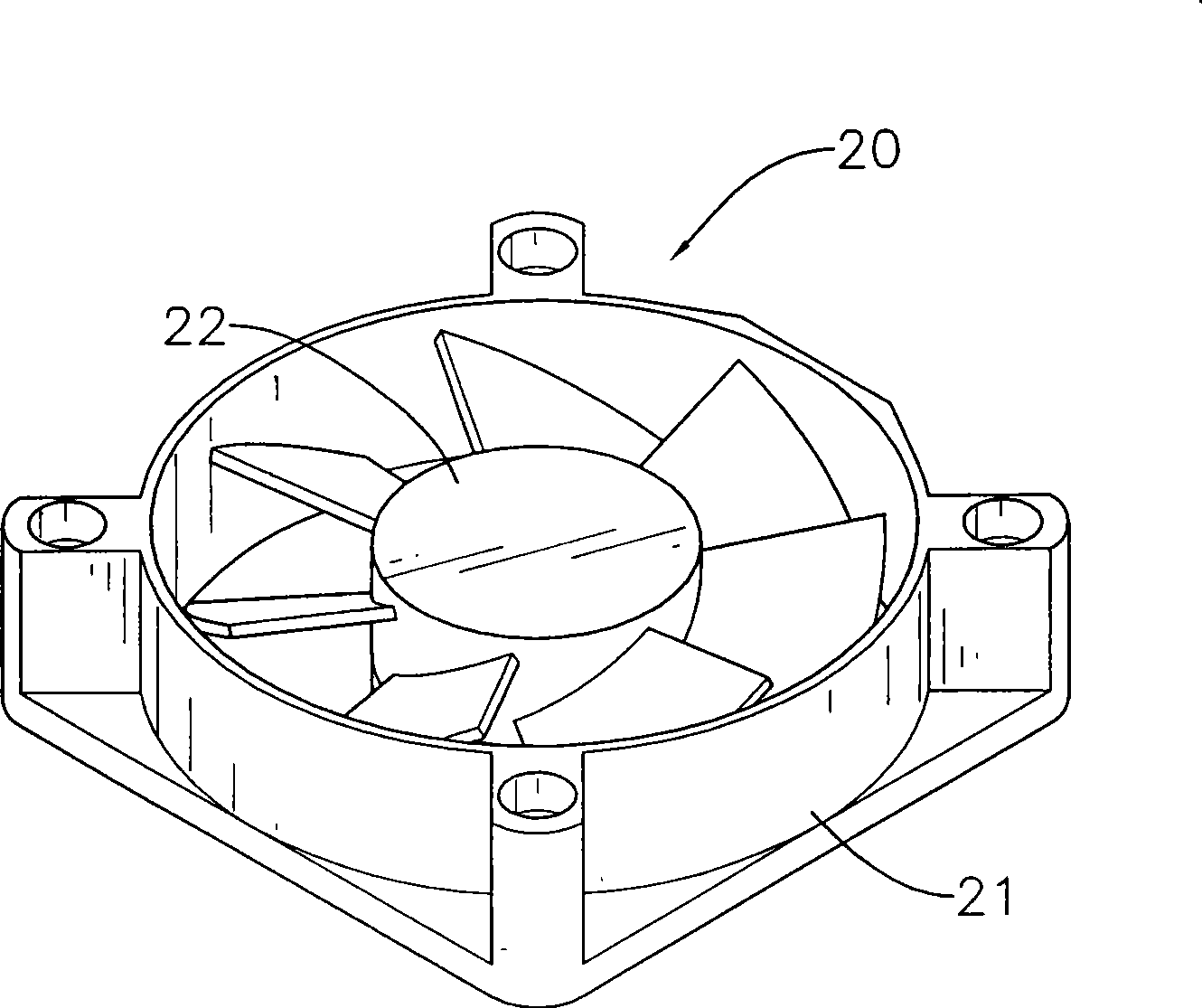

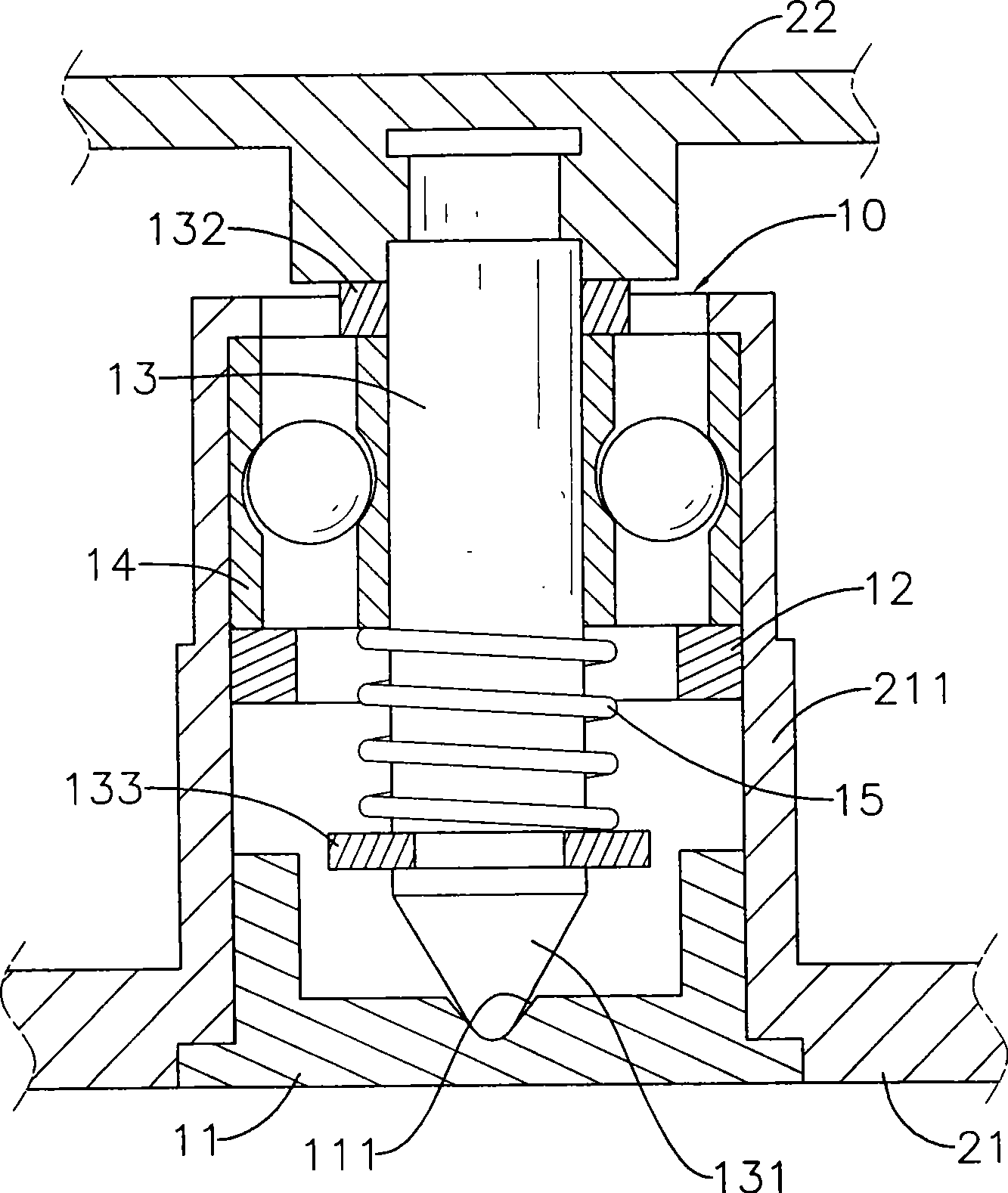

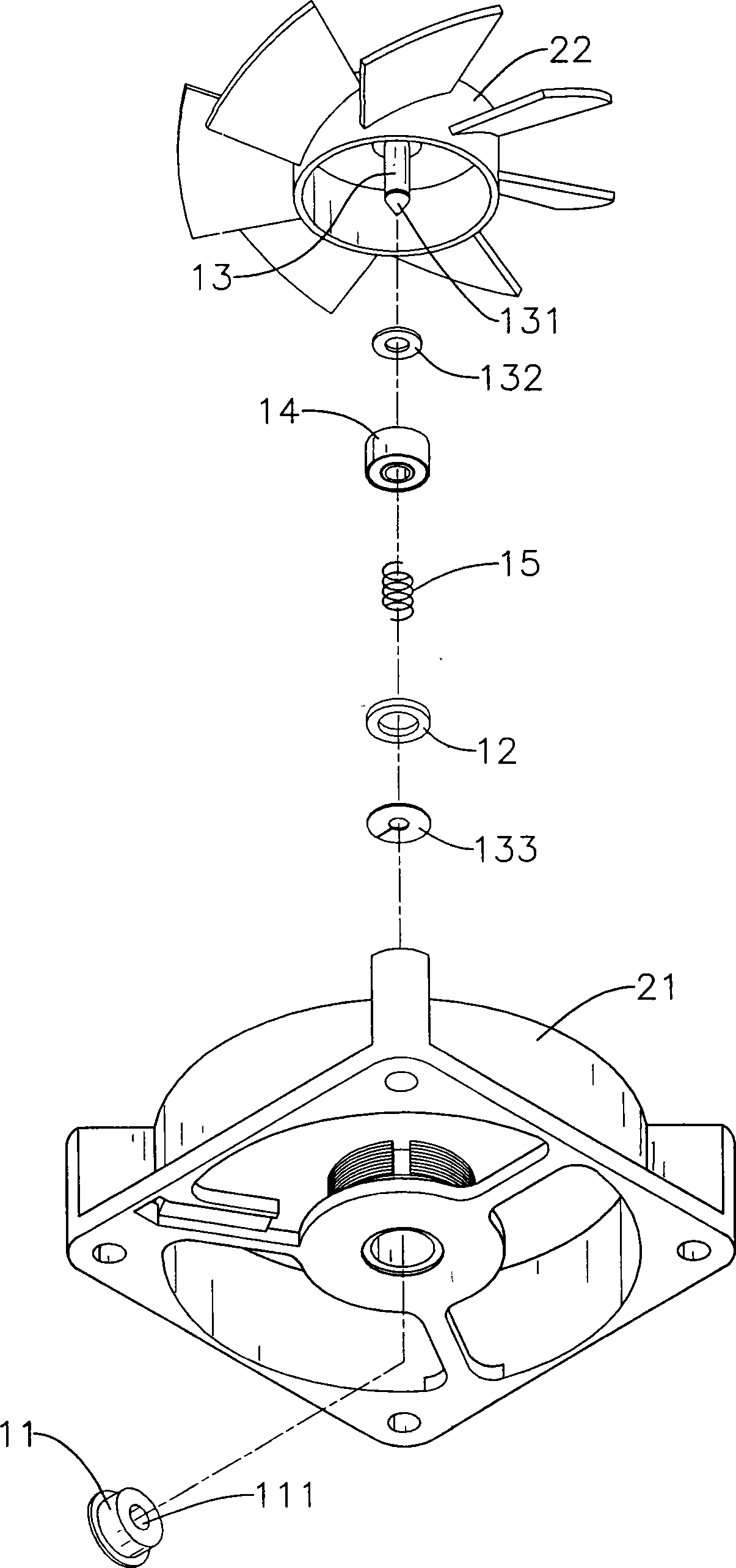

[0033] see figure 1 and figure 2 As shown, the present invention is applied to a fan 20. The fan 20 includes a base 21 and an impeller 22. A shaft tube 211 protrudes from the center of the base 21. Openings are provided at both ends of the shaft tube 211. Among them, The improved fan bearing assembly 10 of the present invention is installed between the shaft tube 211 of the seat body 21 and the impeller 22, and includes a fixed block 11, a positioning ring 12, a mandrel 13, a ball bearing 14 and a spring 15, in:

[0034] The fixed block 11 is a wear-resistant pad, and its cover is fixed on the opening at the bottom of the shaft tube 211, and a tapered groove 111 is concavely formed in the center of its inner surface;

[0035] The positioning ring 12 is fixed on the inner wall of the shaft tube 211;

[0036] The mandrel 13 axially passes through the opening in the shaft tube 211, one end of which is fixed at the center of the impeller 22, and the other end is formed into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com