Gas transverse uniform output device

An output device, horizontal technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

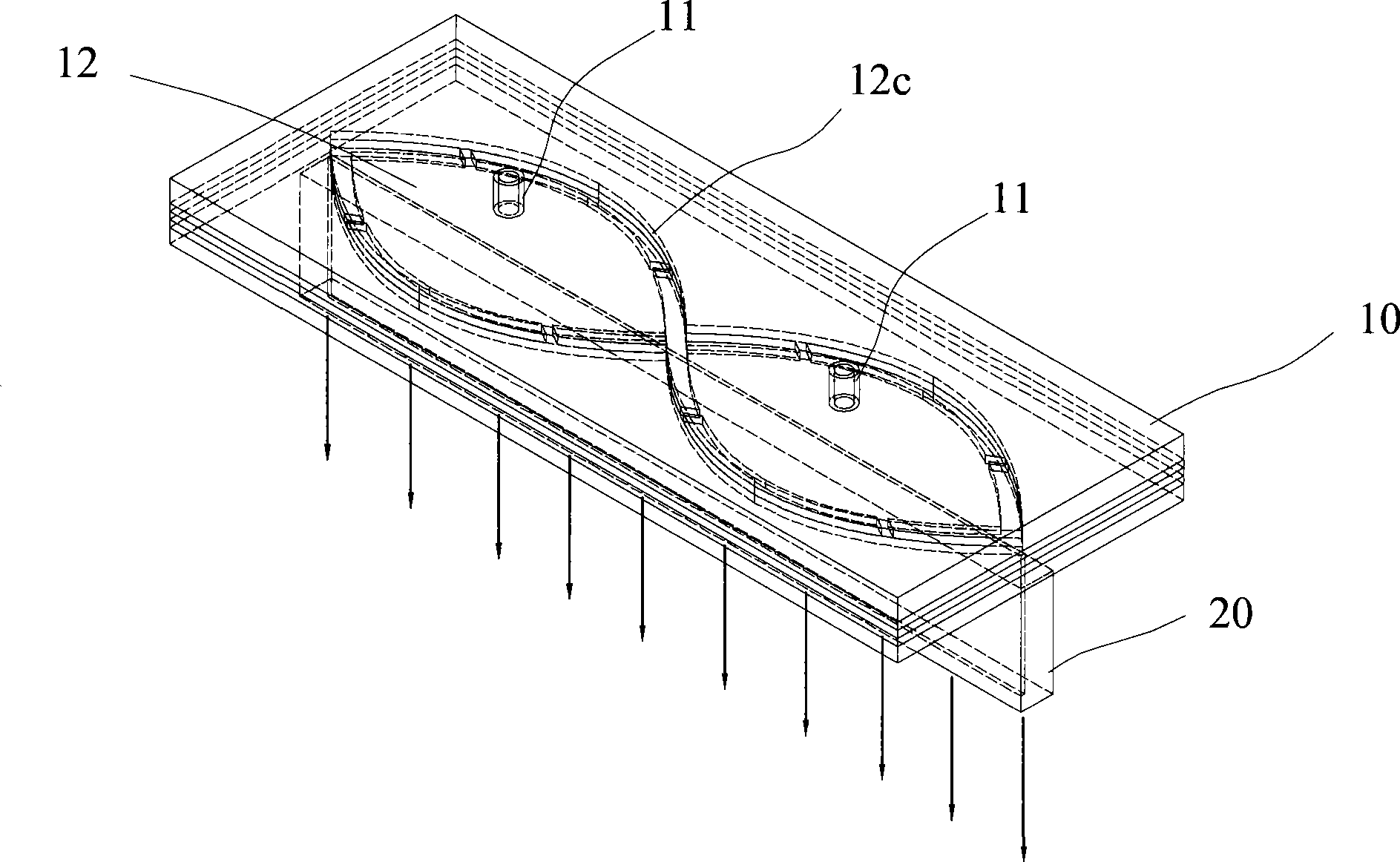

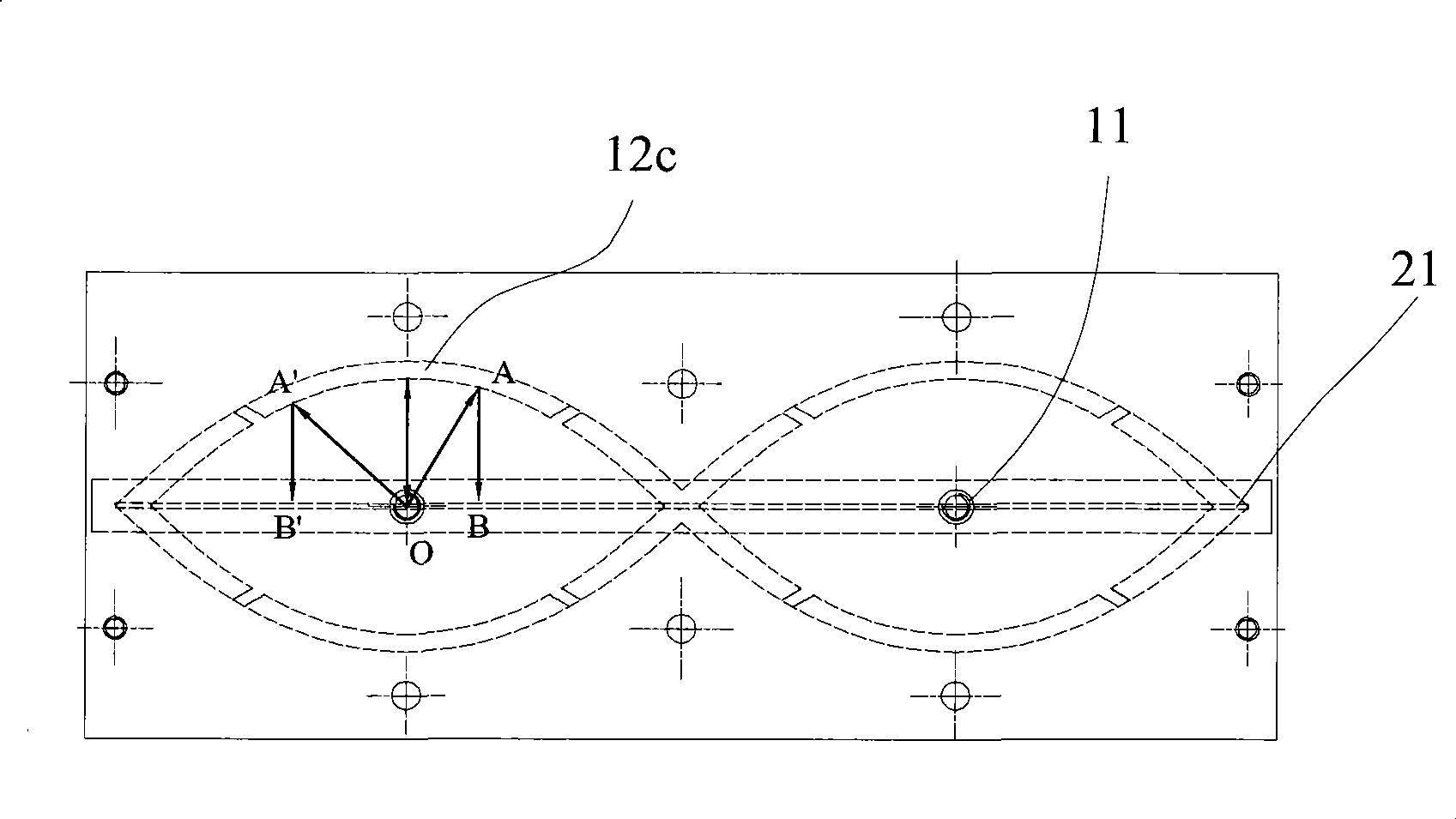

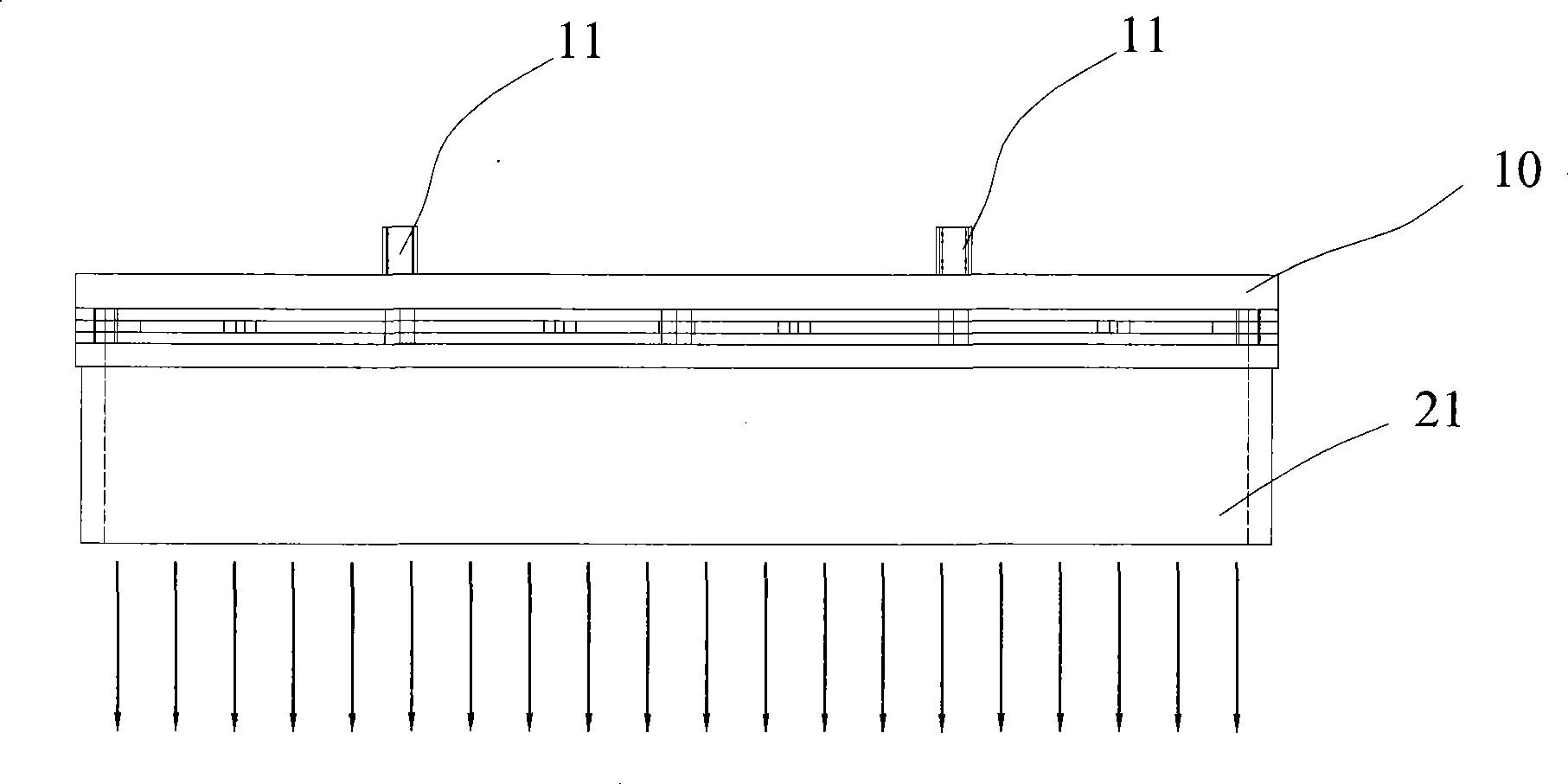

[0036] Such as Figure 1-3 Shown is the first embodiment of the gas horizontal uniform output device of the present invention. The gas horizontal uniform output device includes a gas distribution part 10 and a nozzle part 20 .

[0037] The top surface of the distribution part 10 is provided with an air inlet 11 , and the bottom surface is connected with the nozzle part 20 . The spout part 20 is located on the bottom surface of the distribution part 10 , its length is substantially the same as that of the distribution part 10 , and its width is much smaller than that of the distribution part 10 . A slit 21 is formed in the nozzle part 20 along the longitudinal direction. In this embodiment, the positions of the air inlet 11 and the upper end of the slit 21 in the vertical direction correspond to each other.

[0038] The gas enters the distribution part 10 from the air inlet 11 , passes through the gas channel 12 formed in the distribution part 10 , and flows to the slit 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com