Method for preparing parent metal of nuclear-electric welding material with ultrahigh purity

A technology of purity and welding consumables, which is applied in the field of preparing ultra-high purity nuclear power welding consumable base metals, can solve the problems of inclusions and gas not being able to float up, fail to meet the quality requirements of welding consumables, and reduce purity, and achieve suppression of turbulence and Air entrainment, improvement of purity and yield, and small shrinkage cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

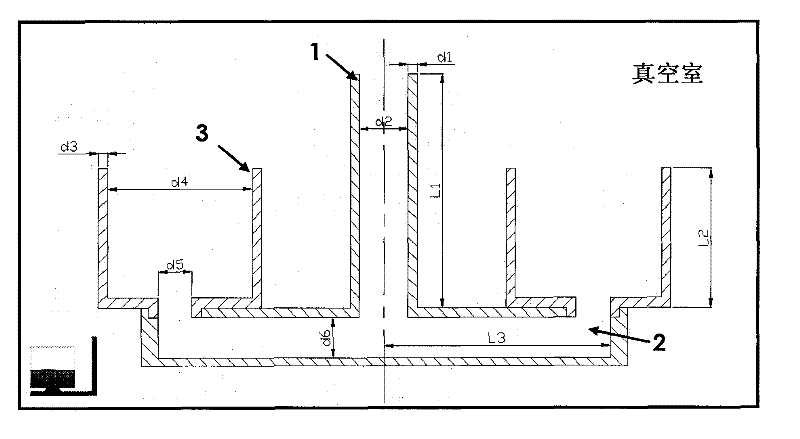

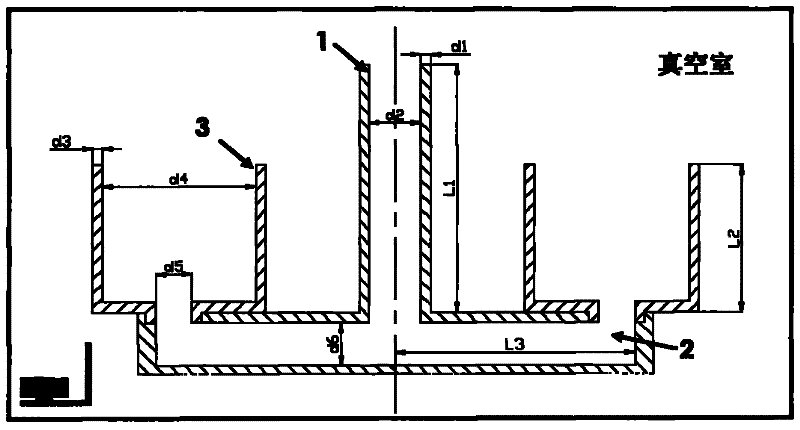

[0015] Example 1: Prepare 316L nuclear-grade welding base material by vacuum pouring process, the specific dimensions of the casting mold: d1=5cm, d2=5cm, d3=3cm, d4=15cm, d5=d6=5cm, L1=40cm, L2=25cm, L3=25cm, pouring speed 0.65m / s, vacuum degree 0.05Mpa, pouring temperature 1600℃, center injection pipe and bottom runner are made of magnesia refractory bricks, ingot mold is made of cast iron. The final ingot has no shrinkage cavity, smooth surface, and the comprehensive impurity content (including oxides, sulfides, other non-metallic inclusions and gases, etc.) is about 87ppm.

Embodiment 2

[0016] Example 2: Prepare 308 nuclear-grade welding consumable base material by vacuum pouring process, the specific dimensions of the casting mold: d1=1.5cm, d2=3cm, d3=3cm, d4=15cm, d5=d6=3cm, L1=50cm , L2=30cm, L3=16cm, pouring speed 0.7m / s, vacuum degree 0.08Mpa, pouring temperature 1620°C, middle injection pipe and bottom runner are made of magnesia refractory bricks, ingot mold is made of cast iron. The final ingot has no shrinkage cavity, smooth surface, and the comprehensive impurity content (including oxides, sulfides, other non-metallic inclusions and gases, etc.) is about 90ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com