Bottom electrode assembly and semiconductor processing equipment

A technology of electrode components and electrode plates, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as easy ignition, reduce the risk of ignition, and extend the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the technical solutions of the present invention, the bottom electrode assembly and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

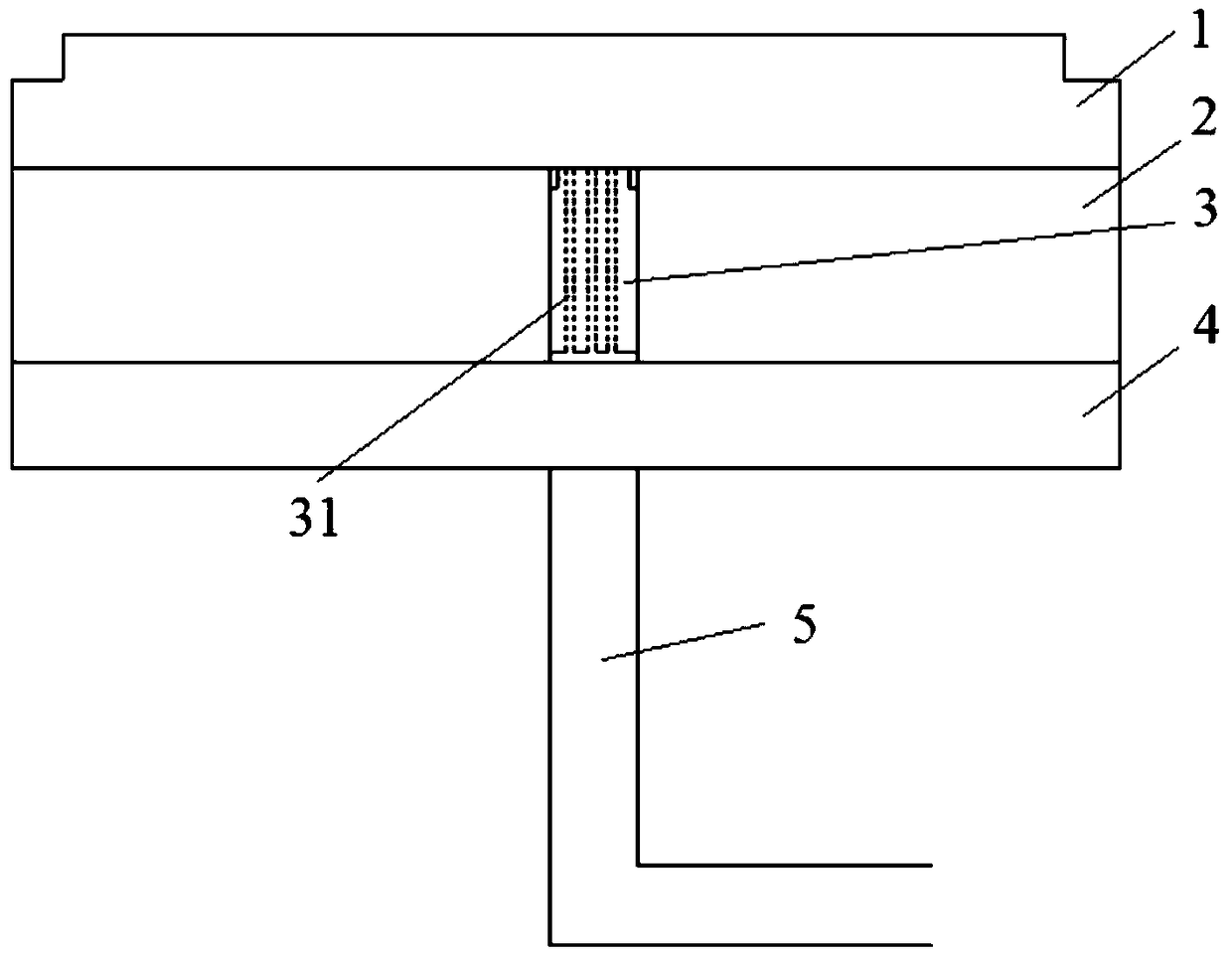

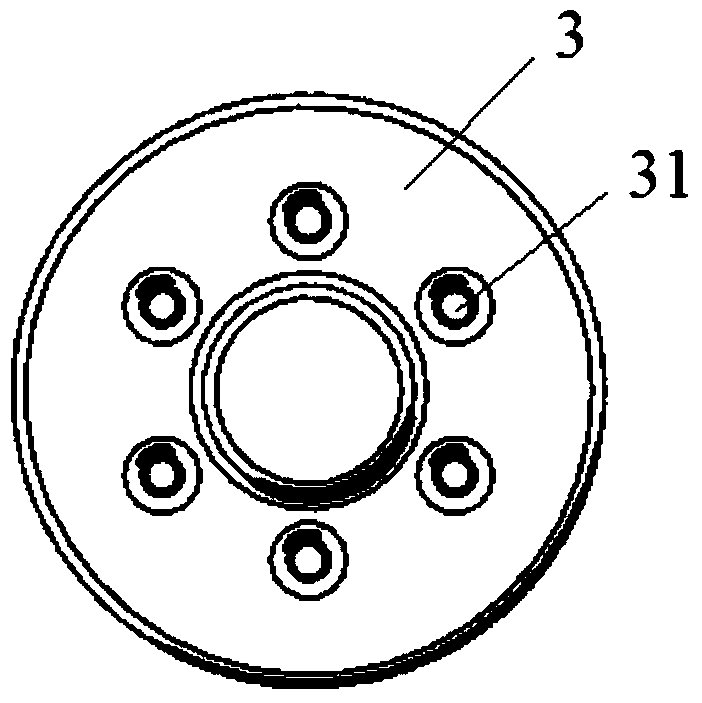

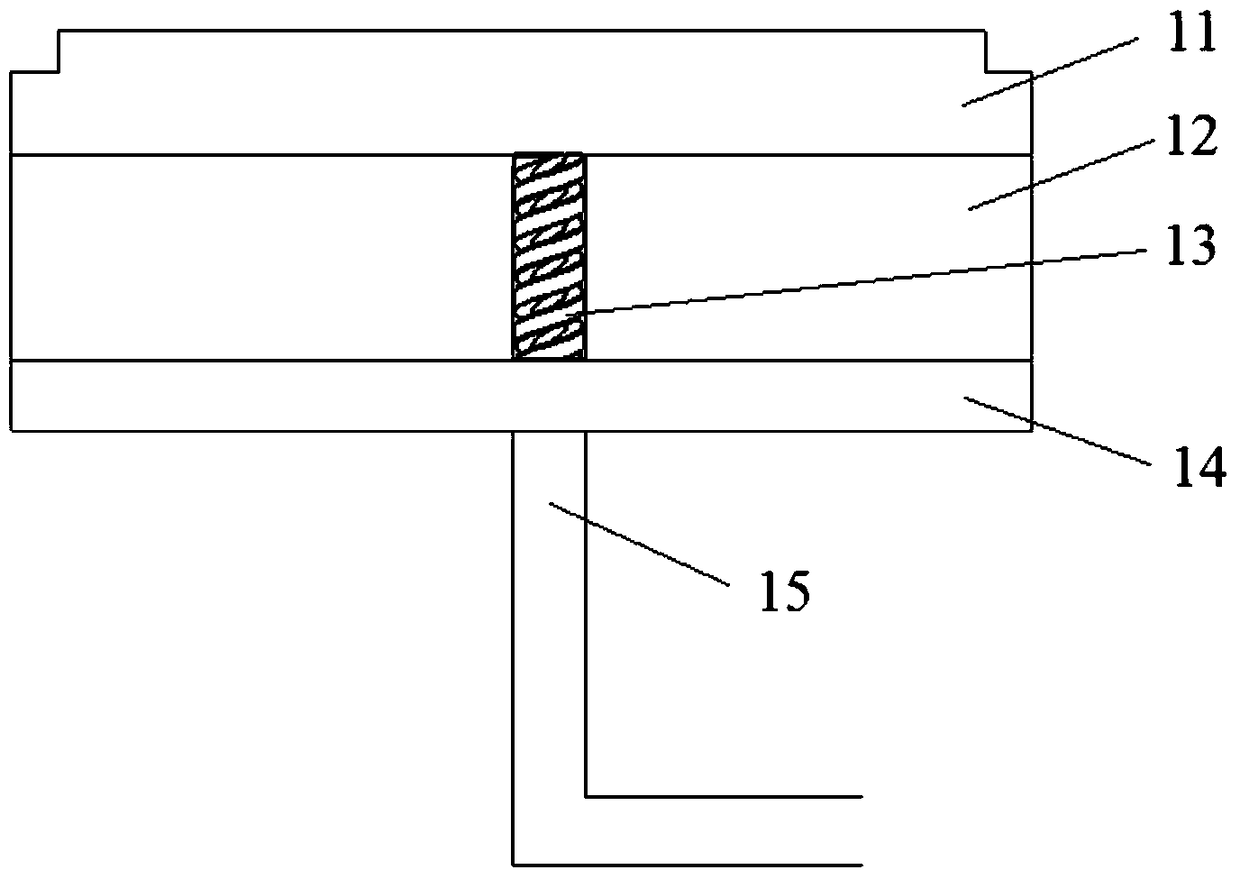

[0035] Please also refer to Figure 3A-3D , The lower electrode assembly includes a lower electrode plate 11 , an insulating dielectric layer 12 and a metal base 14 arranged in sequence from top to bottom. Wherein, in the insulating medium layer 12, an insulating plug 13 penetrating through its thickness direction is provided, and the insulating plug 13 has a gas passage, and the gas outlet end and the inlet end of the gas passage are respectively located on the upper end surface and the lower end surface of the insulating plug 13, through Passing the heat exchange gas into the gas channel can transport the heat exchange gas to the lower surface of the lower electrode plate 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com