Air source heat pump phase-change energy storage defrosting system with super cooling effect

An air-source heat pump and phase-change energy storage technology, which is applied to compressors with reversible cycles, heat pumps, refrigerators, etc., can solve the problems of long defrosting time and insufficient defrosting energy sources, and achieves low cost and simple structure. , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

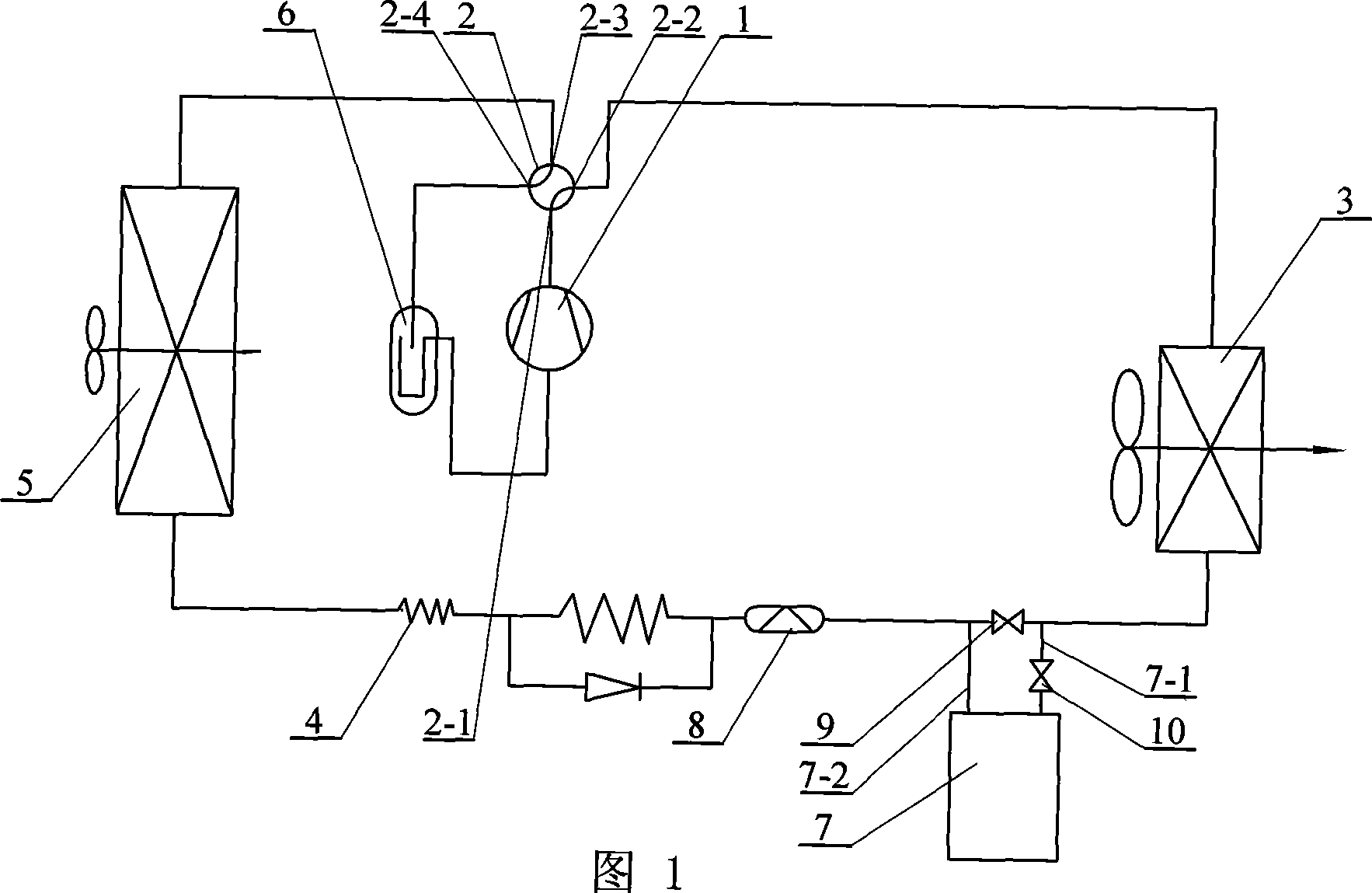

[0008] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. The system of this embodiment includes a compressor 1, a four-way reversing valve 2, an indoor heat exchanger 3, a capillary tube 4, an outdoor heat exchanger 5, and a gas-liquid separator 6 and dry filter 8; between the output end of the compressor 1 and the first valve port 2-1 of the four-way reversing valve 2, between the input end of the compressor 1 and the output end of the gas-liquid separator 6, Between the input end of the gas-liquid separator 6 and the third valve port 2-3 of the four-way reversing valve 2, between the fourth valve port 2-4 of the four-way reversing valve 2 and the outdoor heat exchanger 5, outdoor Between the heat exchanger 5 and the capillary 4, between the capillary 4 and the drier filter 8, between the drier filter 8 and the indoor heat exchanger 3, and between the indoor heat exchanger 3 and the second valve port of the four-way reversing valve 2 2-2 are resp...

specific Embodiment approach 2

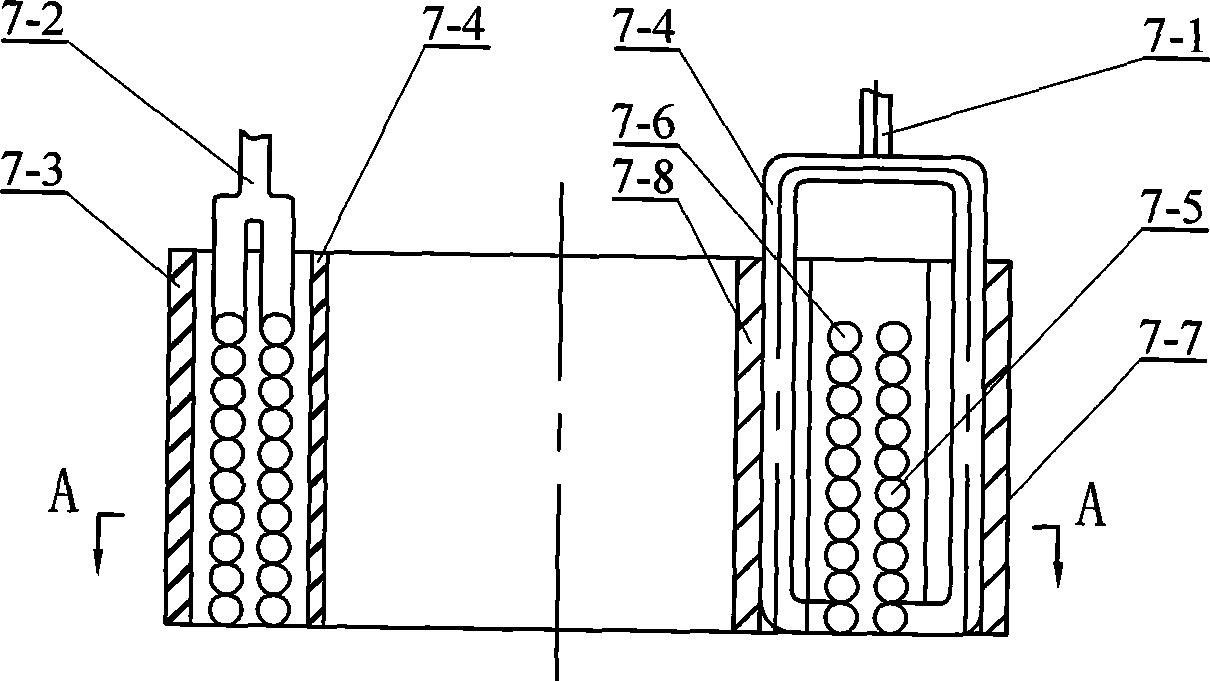

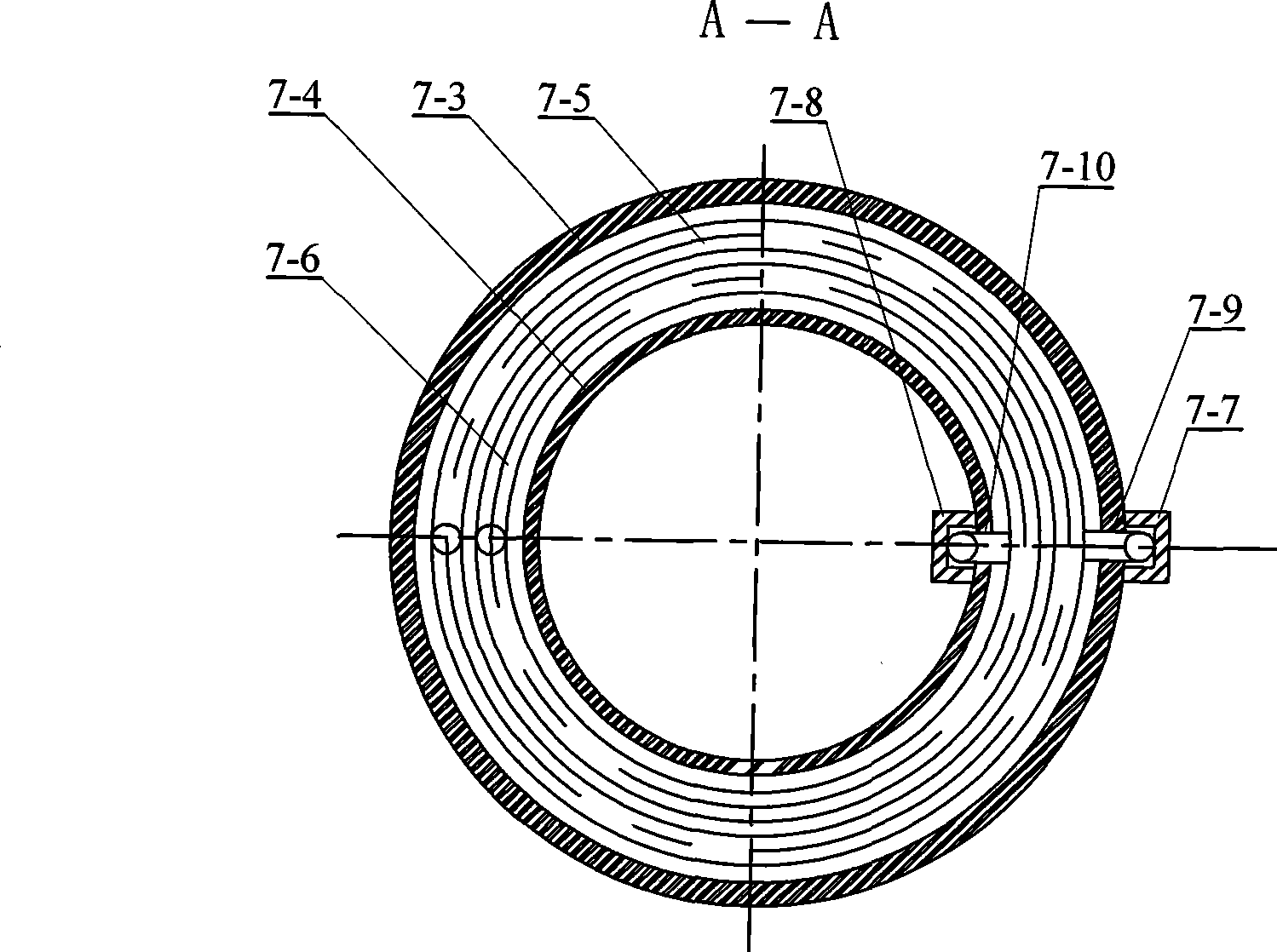

[0009] Specific implementation mode two: combination figure 2 with image 3 Describe this embodiment, the energy storage heat exchanger 7 of this embodiment consists of an outer casing 7-3, an inner casing 7-4, an outer coil 7-5, an inner coil 7-6, and an outer protective pipe groove 7-7 , the inner protective pipe groove 7-8, the inlet and outlet main pipe 7-1 and the inlet and outlet main pipe 7-2; the outer casing 7-3 and the inner casing 7-4 are nested together, and the inner coil 7-6 is arranged Between the outer casing 7-3 and the inner casing 7-4 and set on the inner casing 7-4, the outer coil 7-5 is arranged between the inner coil 7-6 and the outer casing 7-3 and is set on the On the inner coil 7-6, the outer long hole 7-9 is arranged on the pipe wall of the outer pipe 7-3 along the length direction, and the outer long hole 7-9 of the inner pipe 7-4 is connected with the outer long hole 7-9 of the outer pipe 7-3. The corresponding position is provided with an inner l...

specific Embodiment approach 3

[0011] Specific embodiment three: in combination with Fig. 4 and Figure 5 To illustrate this embodiment, the energy storage heat exchanger 7 of this embodiment is composed of a shell 7-11, a heat exchange tube bundle 7-12, two tube sheets 7-13, an inlet and outlet main pipe 7-1, and an inlet and outlet main pipe 7-2 ; The two tube sheets 7-13 are fixed in the shell 7-11, the heat exchange tube bundle 7-12 is arranged in the shell 7-11, and the two ends of the heat exchange tube bundle 7-12 are fixed in the two tube sheets In the tube hole of 7-13, one end of the inlet and outlet main pipe 7-1 is connected with one end of the housing 7-11, one end of the inlet and outlet main pipe 7-2 is connected with the other end of the housing 7-11, and the end of the housing 7-11 A phase change material injection port 7-14 is provided on the upper end near the inlet and outlet main pipe 7-1, and a phase change material outlet 7-15 is provided on the lower end of the housing 7-11 near the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com