System and method for testing electric resistivity of thin film thermoelectricity material

A test system and test method technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems affecting test accuracy, different correction coefficients, and measurement results, and achieve high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

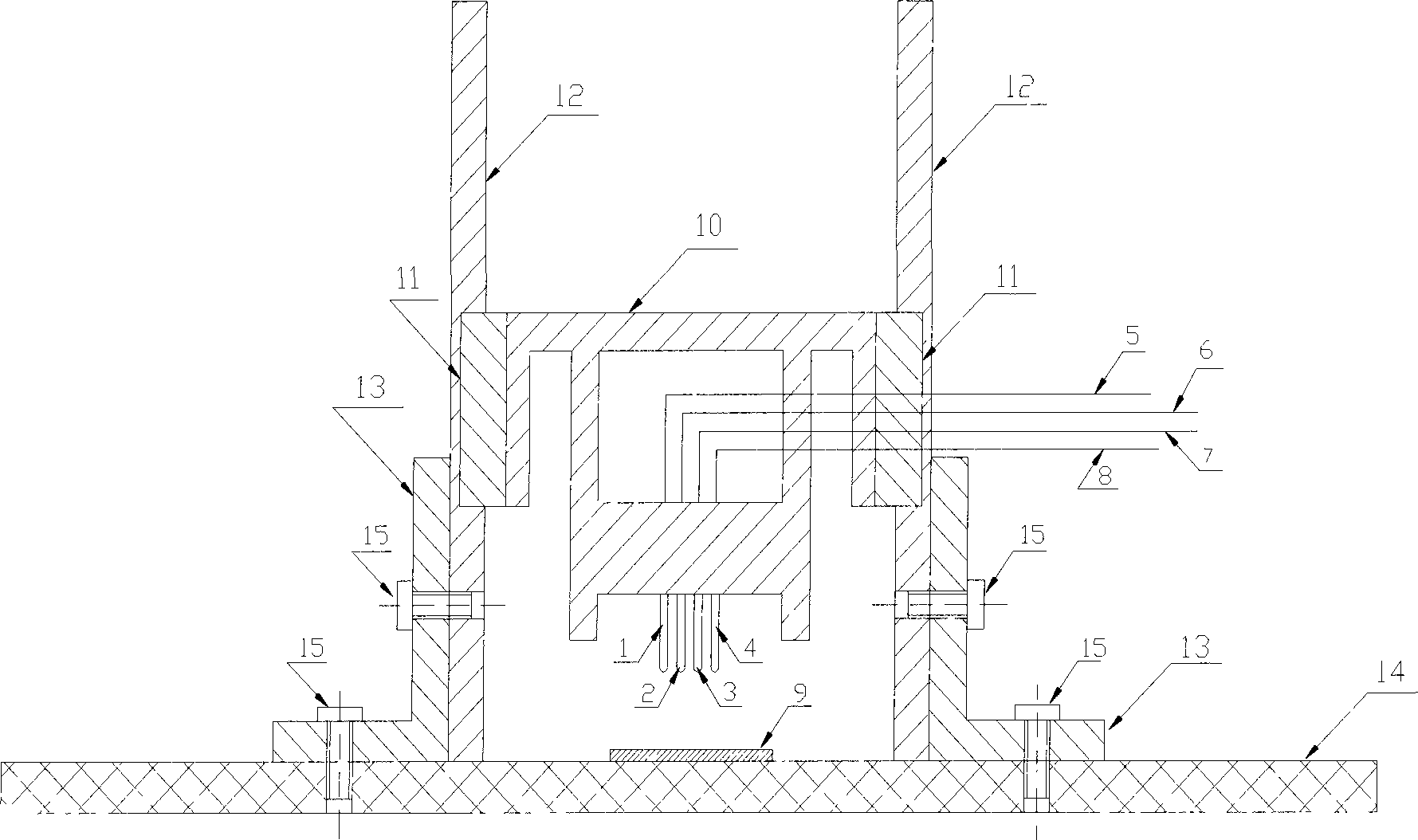

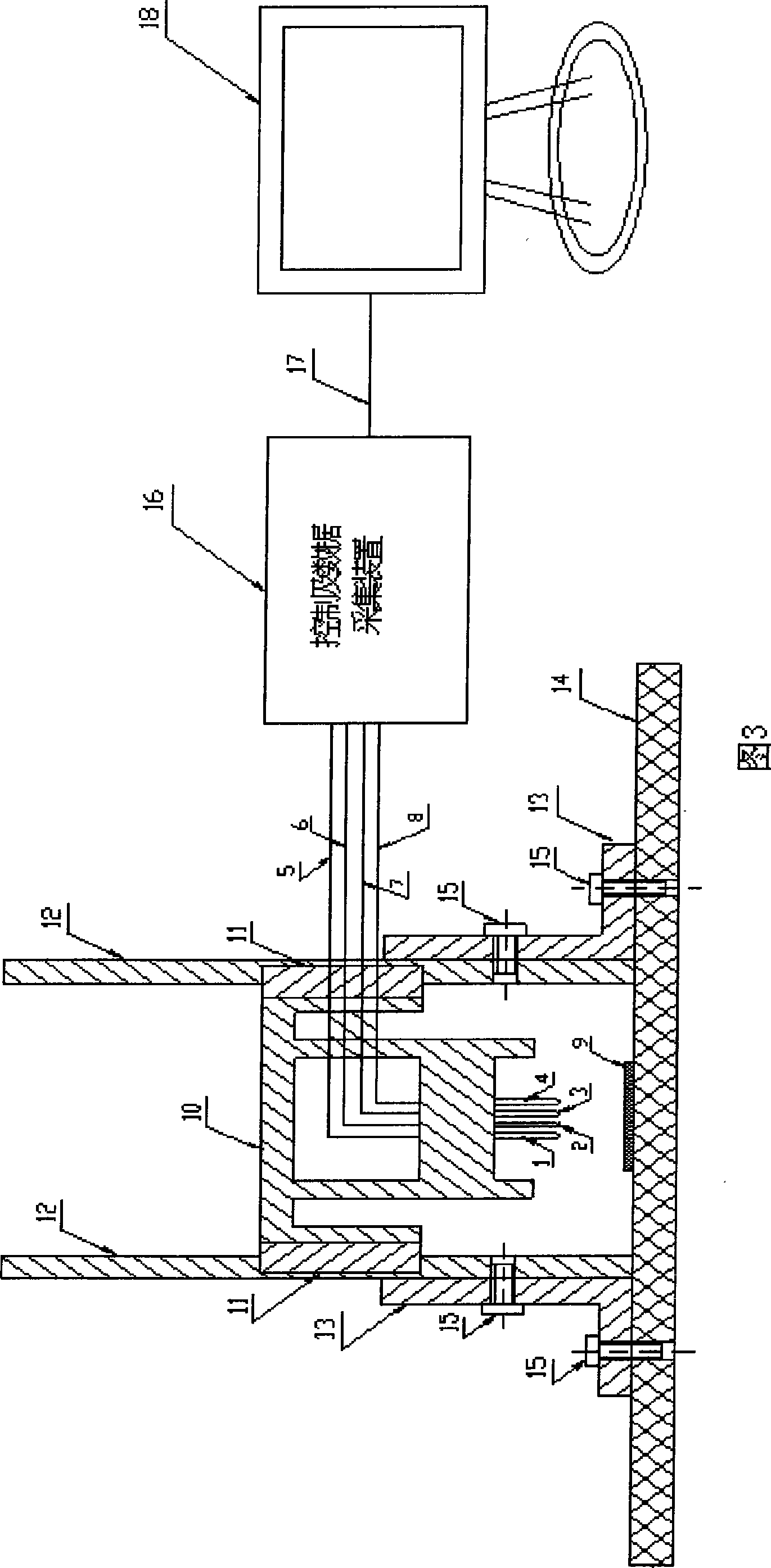

[0017] Further illustrate the resistivity of testing N-type Bi2Te3 thermoelectric material film below in conjunction with accompanying drawing:

[0018] Such as figure 1 Shown: The test fixture is composed of No. 1 probe 1, No. 2 probe 2, No. 3 probe 3, No. 4 probe 4, sample to be tested 9, probe support frame 10, slider 11, guide rail 12 , guide rail support 13, base 14, and fixing screws 15; No. 1 probe 1, No. 2 probe 2, No. 3 probe 3, and No. 4 probe 4 are respectively fixed on the probe support frame 10, and the The needle support frame 10 is connected with the slider 11; through the sliding of the slider 11 on the guide rail 12, the No. 1 probe 1, the No. 2 probe 2, the No. 3 probe 3, and the No. 4 probe 4 move up and down ; The sample to be tested 9 is placed on the base 14, and when the probe support frame 10 falls, its surface is closely connected with the No. 1 probe 1, the No. 2 probe 2, the No. 3 probe 3, and the No. 4 probe 4. Contact; the guide rail support 13 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com