Touch control electrode layer and display panel

A touch electrode and display panel technology, applied in static indicators, electrical digital data processing, instruments, etc., can solve the problems of display function and touch function signal error, signal interference, etc., and achieve the effect of improving induction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

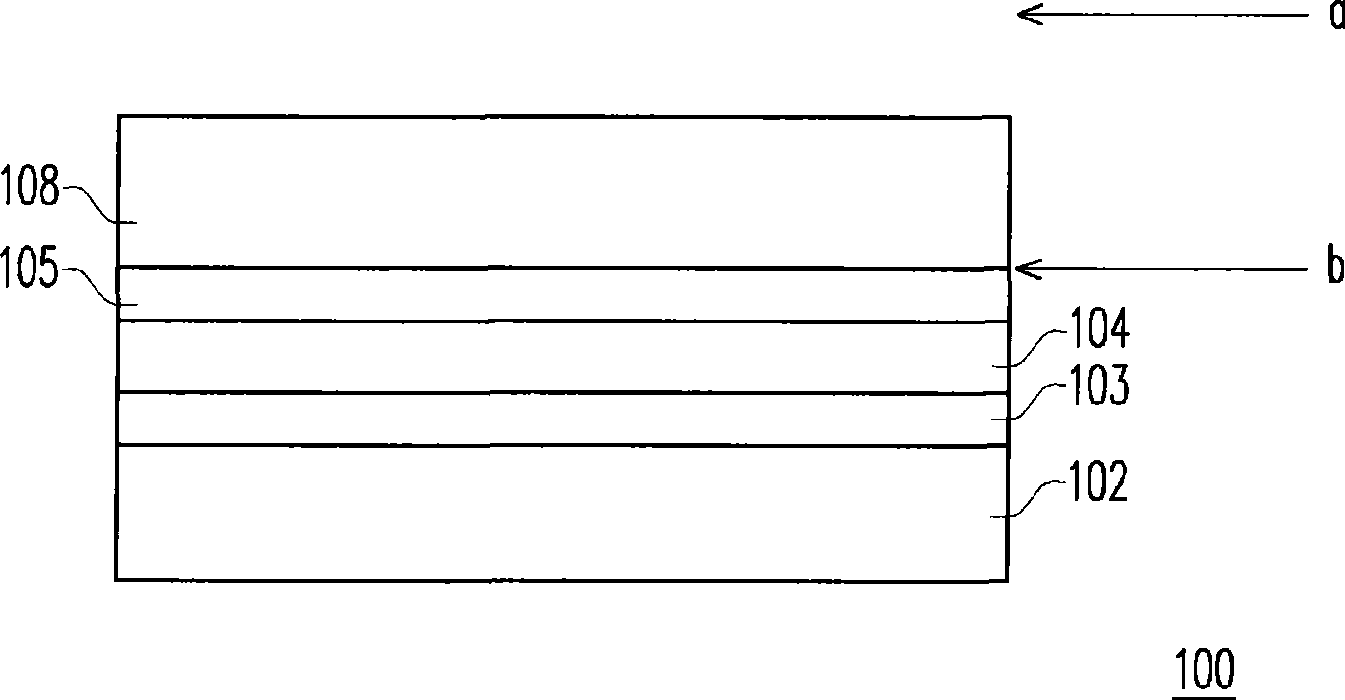

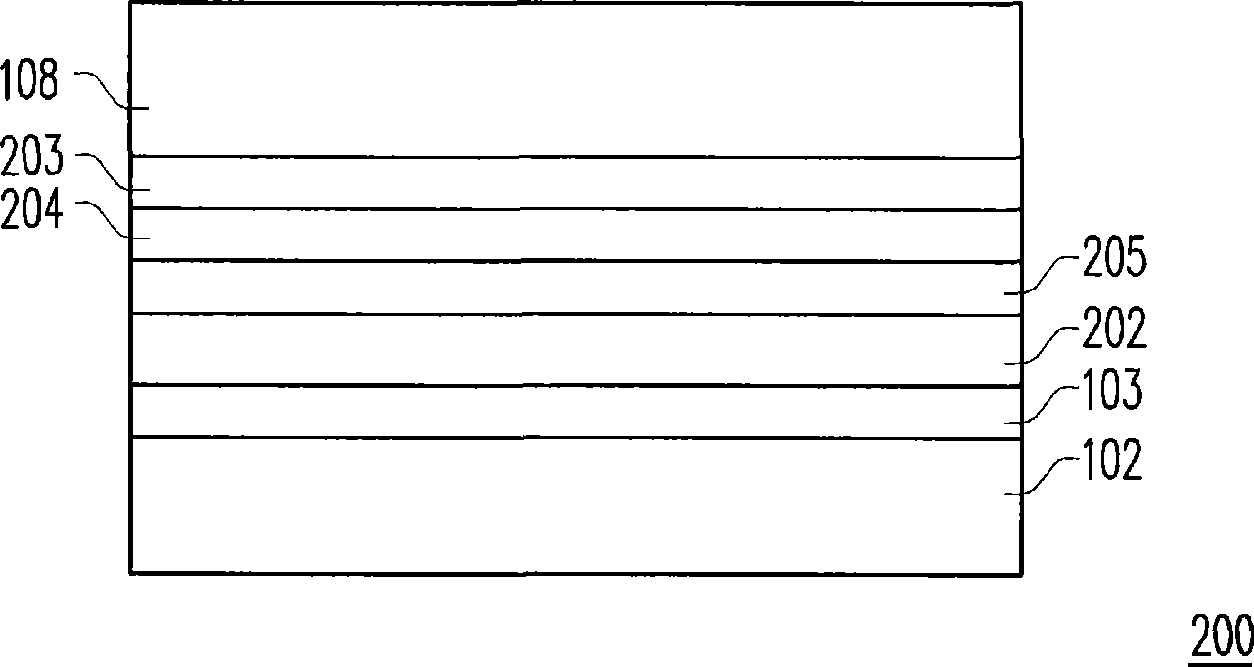

[0068] figure 2 is a schematic cross-sectional view of the display panel according to the first embodiment of the present invention. Please refer to figure 2 , the display panel 200 of this embodiment includes a first substrate 102 , a pixel array 103 , a second substrate 108 , a display medium 202 and a touch electrode layer 203 .

[0069] The first substrate 102 and the second substrate 108 can be made of glass, plastic, silicon, metal or other suitable substrate materials. The second substrate 108 is located opposite to the first substrate 102 .

[0070] The pixel array 103 is located on the first substrate 102 . The pixel array 103 is composed of several pixel structures, including multiple active components, multiple scan lines, multiple data lines, and multiple pixel electrodes (not shown). The active component is electrically connected to the scan line and the data line, and the pixel electrode is electrically connected to the corresponding active component. The ...

no. 2 example

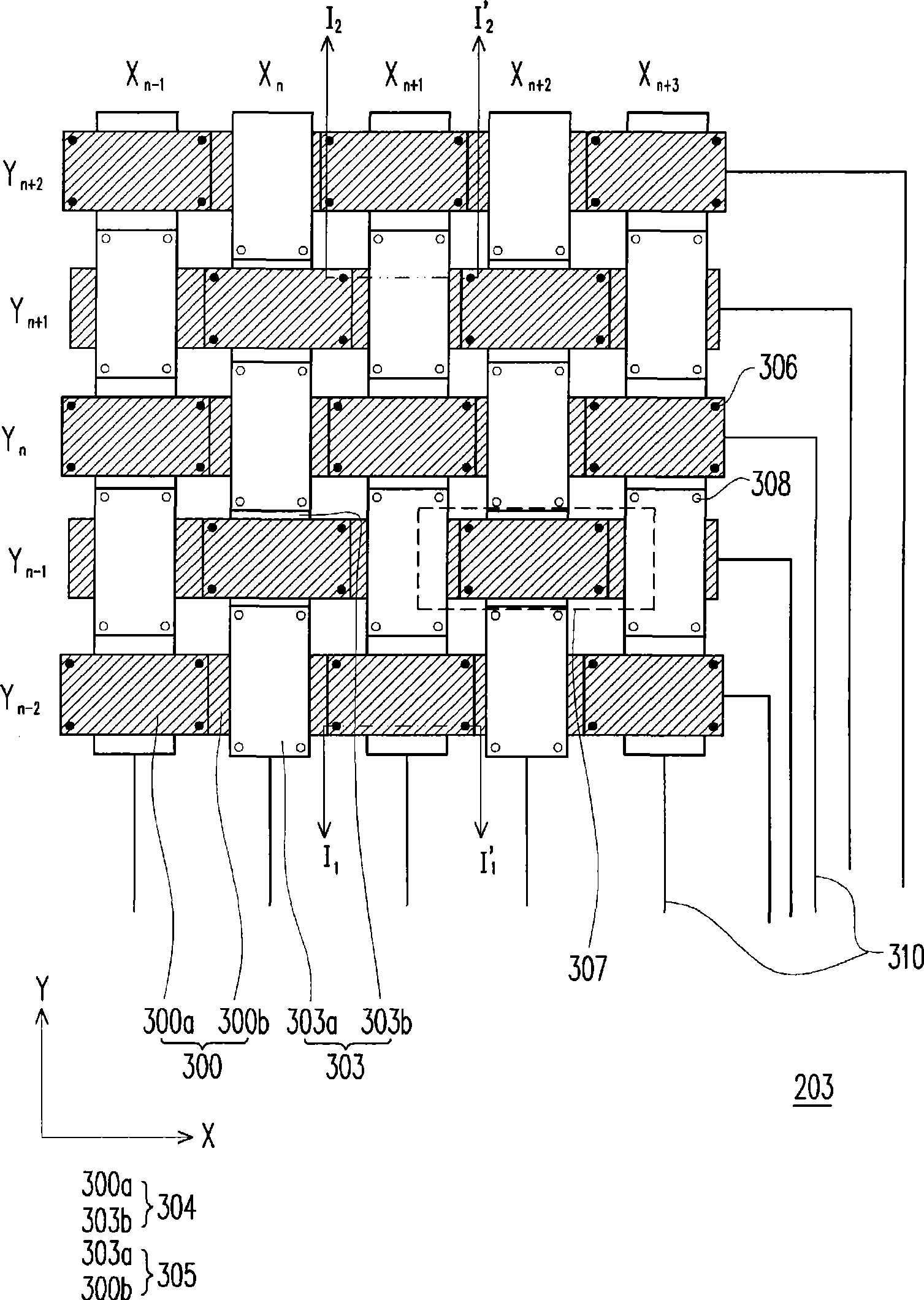

[0082] FIG. 7 is a schematic top view of a touch electrode layer according to a second embodiment of the present invention. Please refer to Figure 7, this embodiment and image 3 The touch electrode layer 203 of the embodiment is similar, except that the touch electrode layer 700 of this embodiment is divided into at least two regions. In FIG. 7 , the touch electrode layer 700 is divided into four regions A, B, C, and D, but the number of regions is not limited in the present invention.

[0083] In FIG. 7 , the first touch electrode 706 and the second touch electrode 708 in area A are different from the first touch electrodes 702, 716, 718 and second touch electrodes in the other three areas B, C, and D. 704, 720, 722 insulation. Moreover, each of the first touch electrodes 706 and each of the second touch electrodes 708 in the area A is electrically connected to a peripheral circuit 712 respectively. Similarly, the first touch electrodes 702 and the second touch electrodes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com