Backlight module and uses thereof

A backlight module and backplane technology, applied in optics, nonlinear optics, lighting devices, etc., can solve the problems of increased usage of rubber pads, increased costs, and fit tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

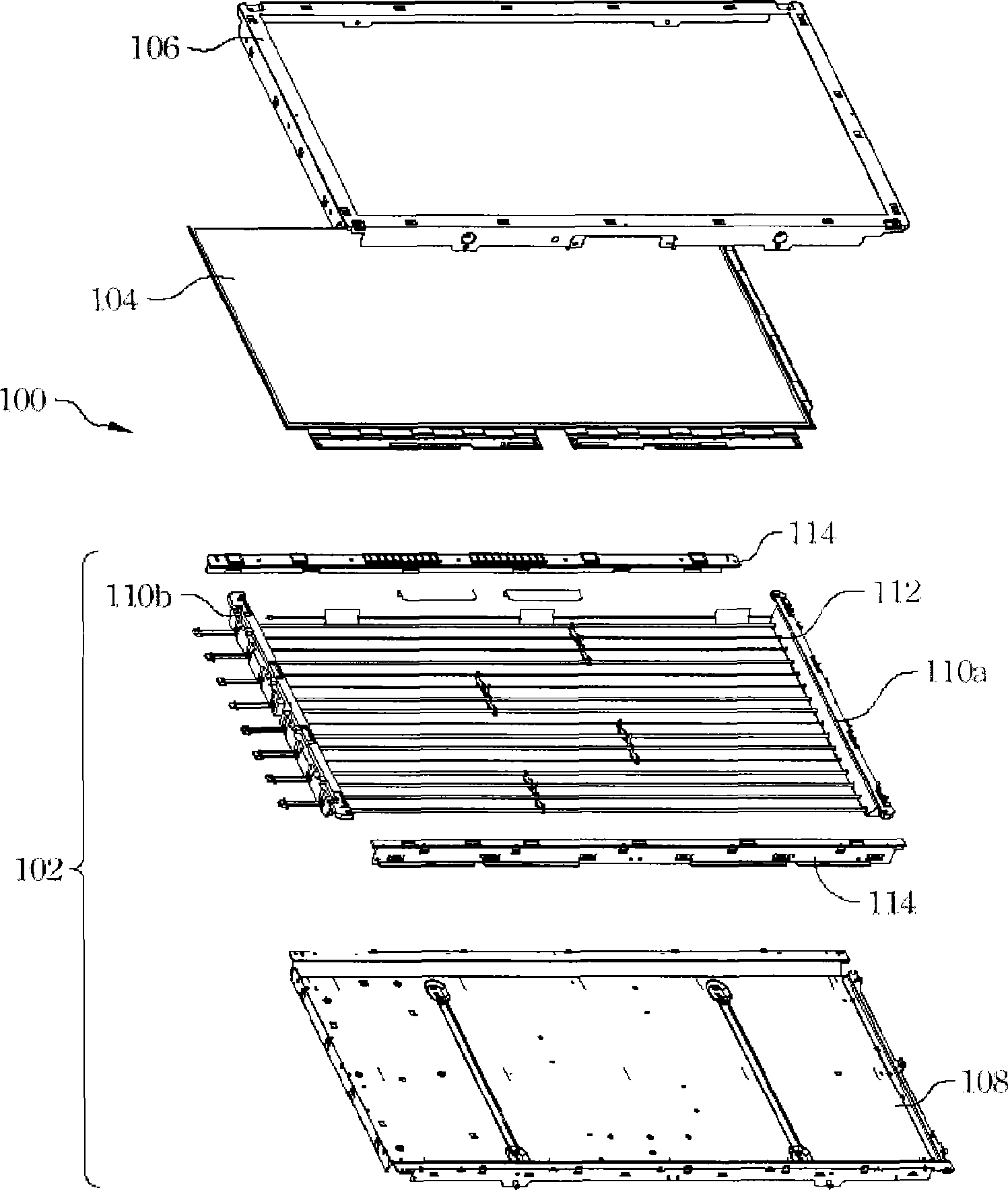

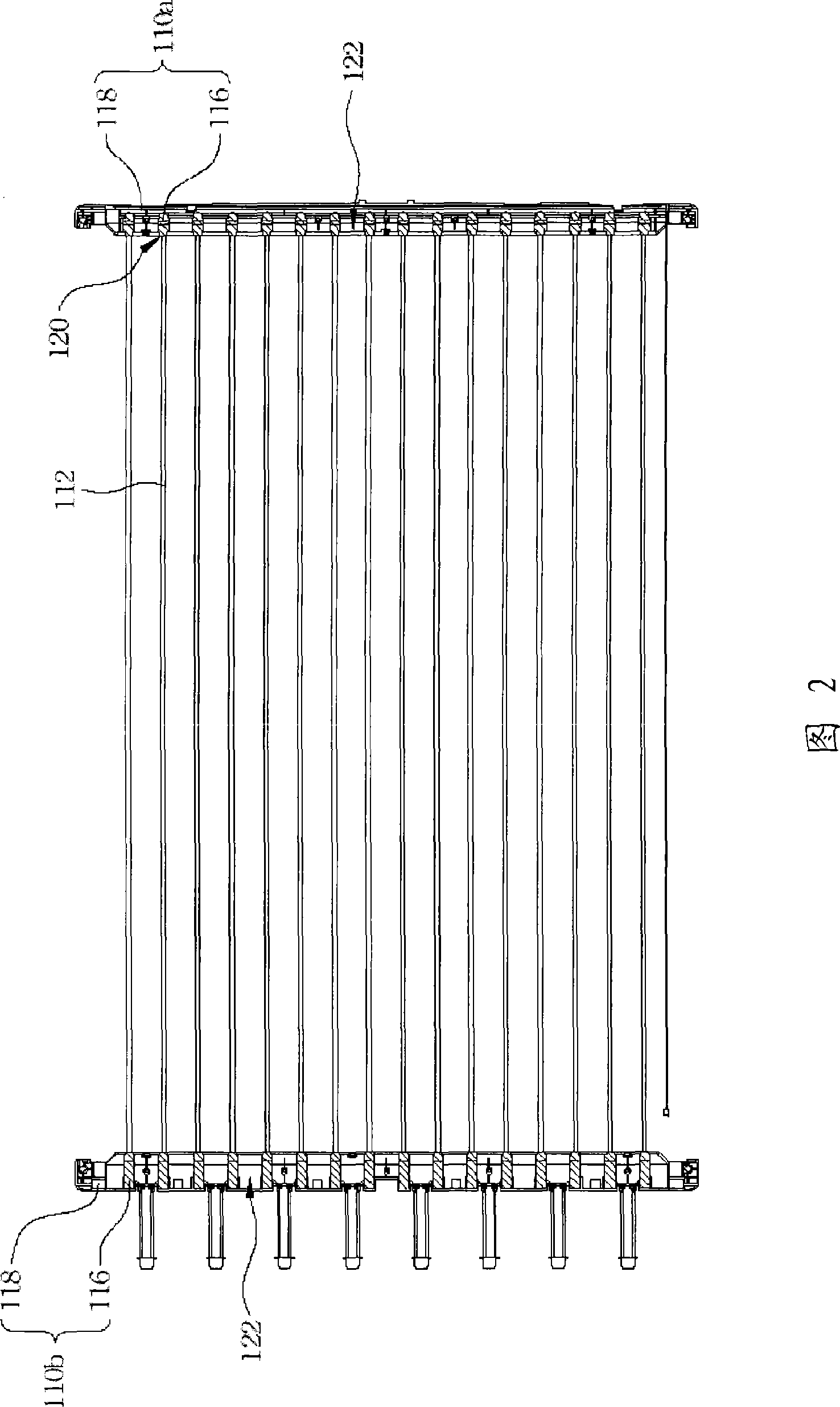

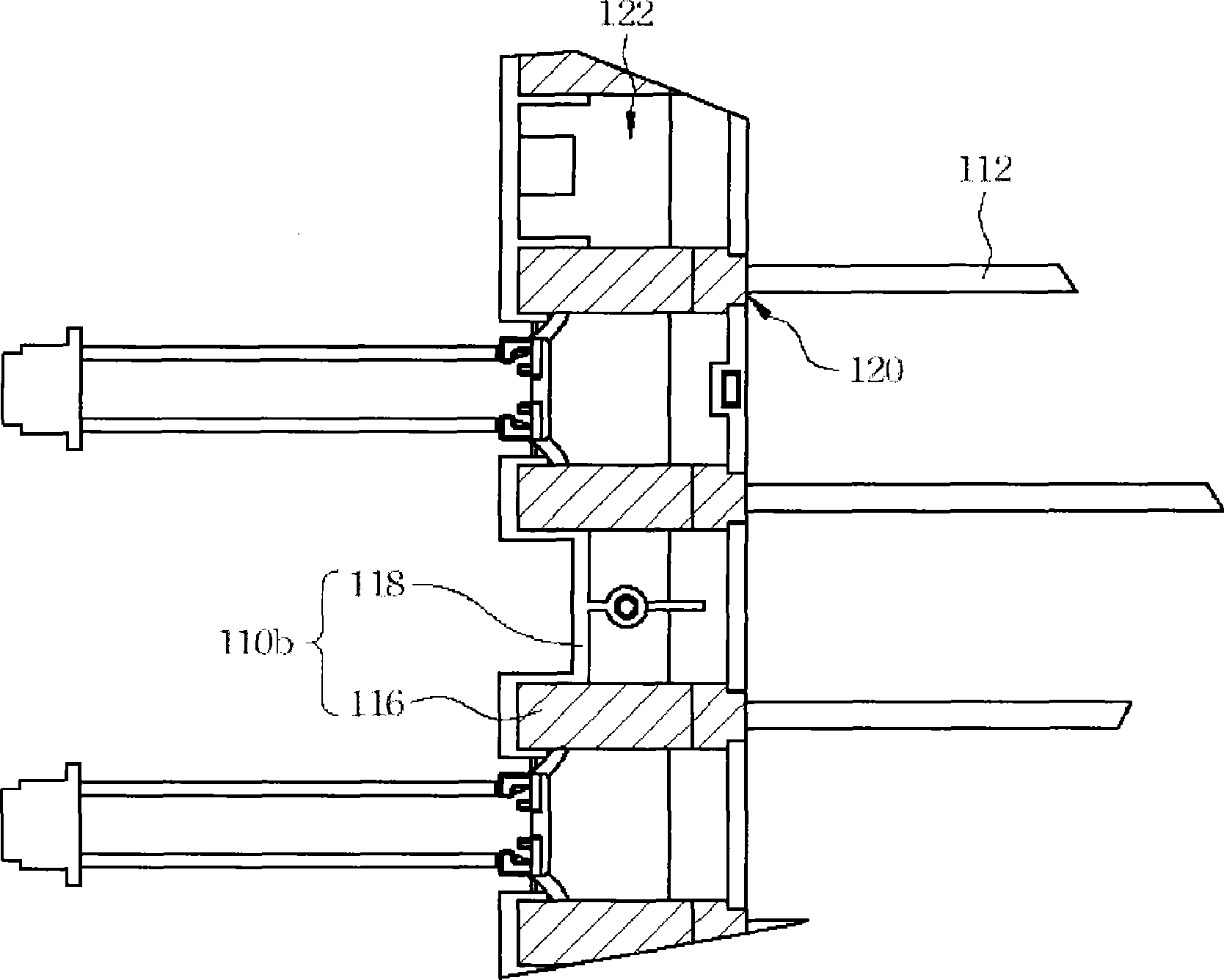

[0023] The invention discloses a backlight module and its application. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 1 to Figure 4 icon of the .

[0024] Please refer to figure 1 , which shows an assembly system diagram of a liquid crystal display according to a preferred embodiment of the present invention. The liquid crystal display 100 is mainly composed of a backlight module 102, a display panel 104 and a front frame 106, wherein the backlight module 102 is arranged on the back of the display panel 104 to provide a backlight for the display panel 104, and the front frame 106 is set on the display panel 104 and combined with the backlight module 102. In an exemplary embodiment of the present invention, the display panel 104 is a liquid crystal display panel, wherein the liquid crystal display panel is mainly composed of a color filter, a thin film transistor substrate, and a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com