Display device and method of manufacturing display device

A technology for a display device and a manufacturing method, applied in identification devices, semiconductor/solid-state device manufacturing, optics, etc., can solve the problems of increased manufacturing man-hours, insufficient, complex structures, etc., and achieve reduced cut-off current, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the display device of the present invention will be described in detail with reference to the drawings.

[0037] In all the drawings for explaining the embodiments, components having the same functions are denoted by the same reference numerals, and detailed description thereof will be omitted.

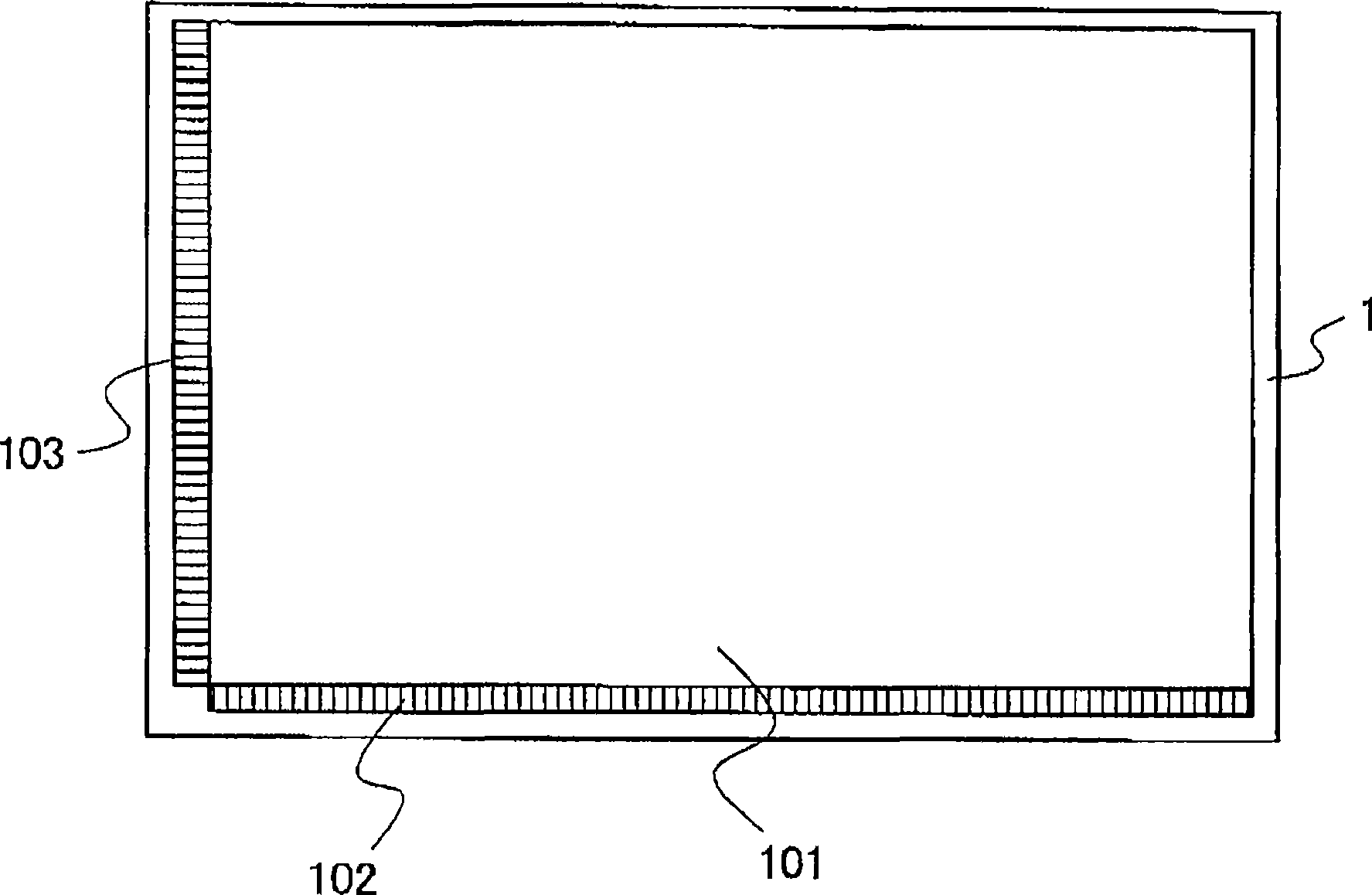

[0038] figure 1 It is a diagram showing an insulating substrate on which a thin film transistor is formed, constituting the display device of the present invention. The insulating substrate 1 is composed of, for example, a glass substrate using glass as a material.

[0039] A display region 101 is formed on the insulating substrate 1 . A plurality of pixels are formed in the display area. Drive circuits such as an RGB switch 102, a shift register 103, and the like are formed in a peripheral area outside the display area. These drive circuits are built on the insulating substrate 1 .

[0040] The pixels in the display area 101 use amorphous silicon thin film tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com