Lathe automatic feeding device for axle machining

An automatic feeding and lathe technology, which is applied to metal processing equipment, automatic/semi-automatic lathes, turning equipment, etc., can solve the problems of insufficient equipment utilization, high scrapping, and long time consumption, and achieve labor cost reduction, reasonable overall structure, Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

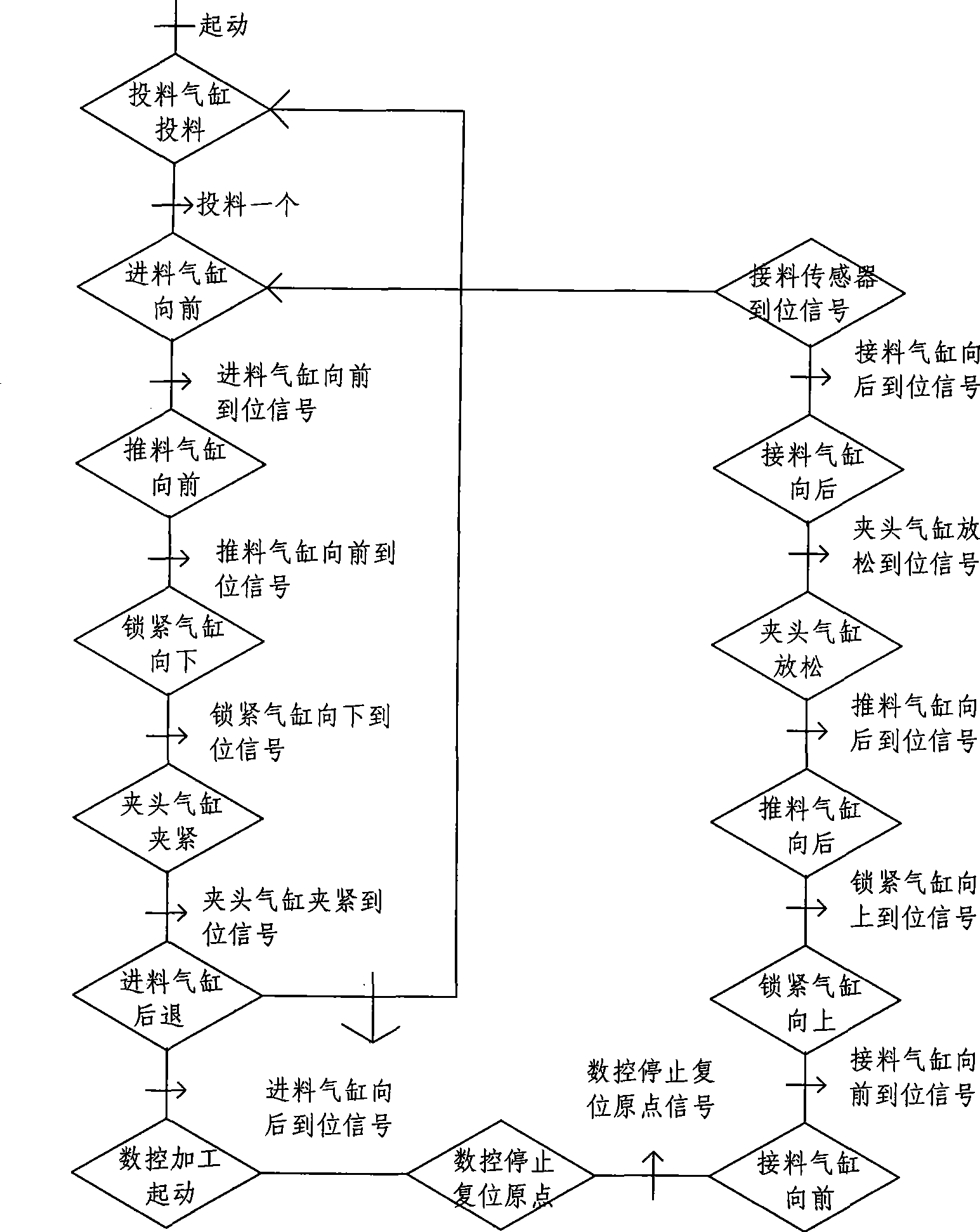

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

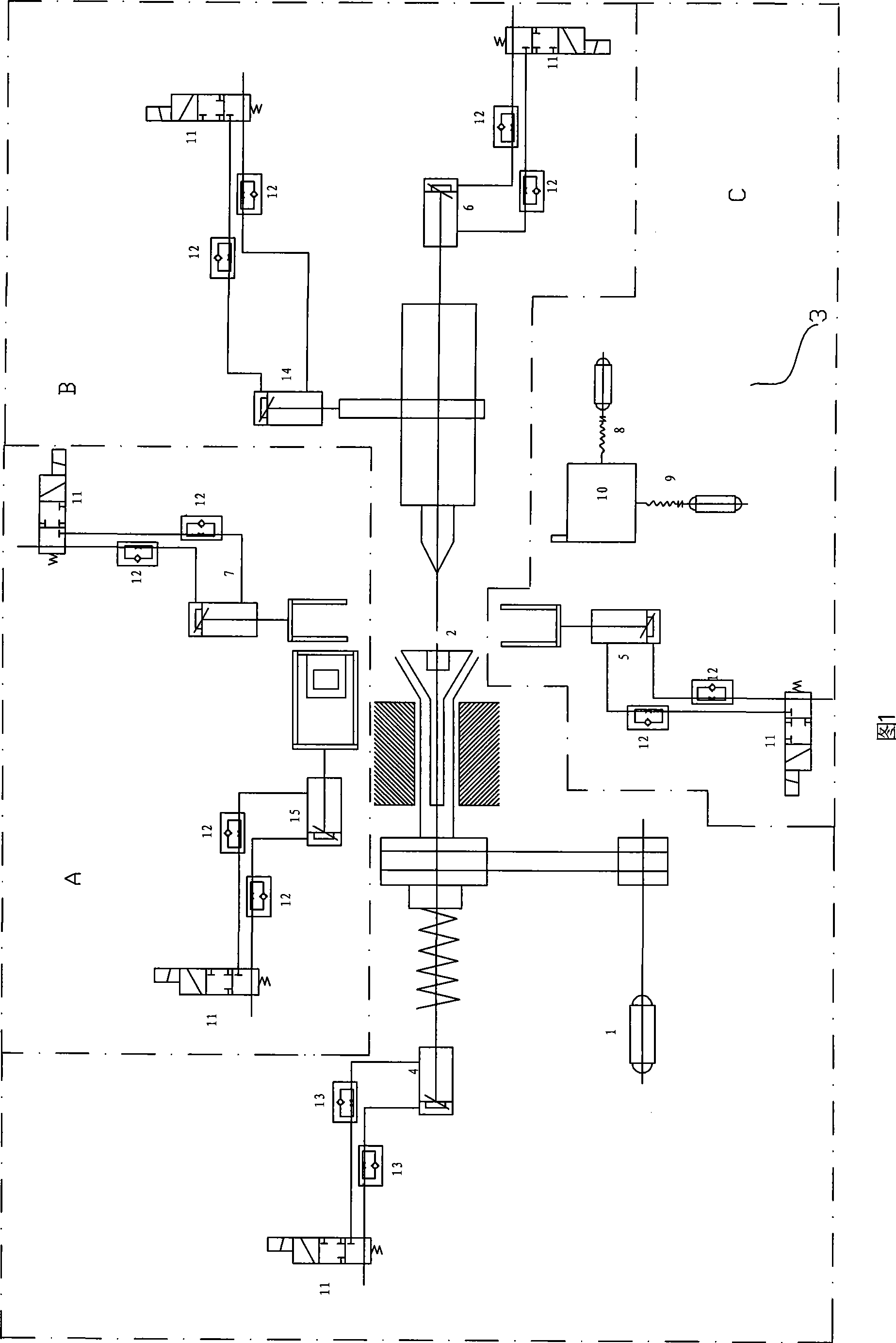

[0039] As shown in the figure, a lathe automatic feeding device for shaft processing, which includes a lathe body, a numerical control system and a control electric box, is similar to the traditional one, and the key point is that a feeding mechanism is installed on the lathe body A. Clamping mechanism B, discharging mechanism C, where:

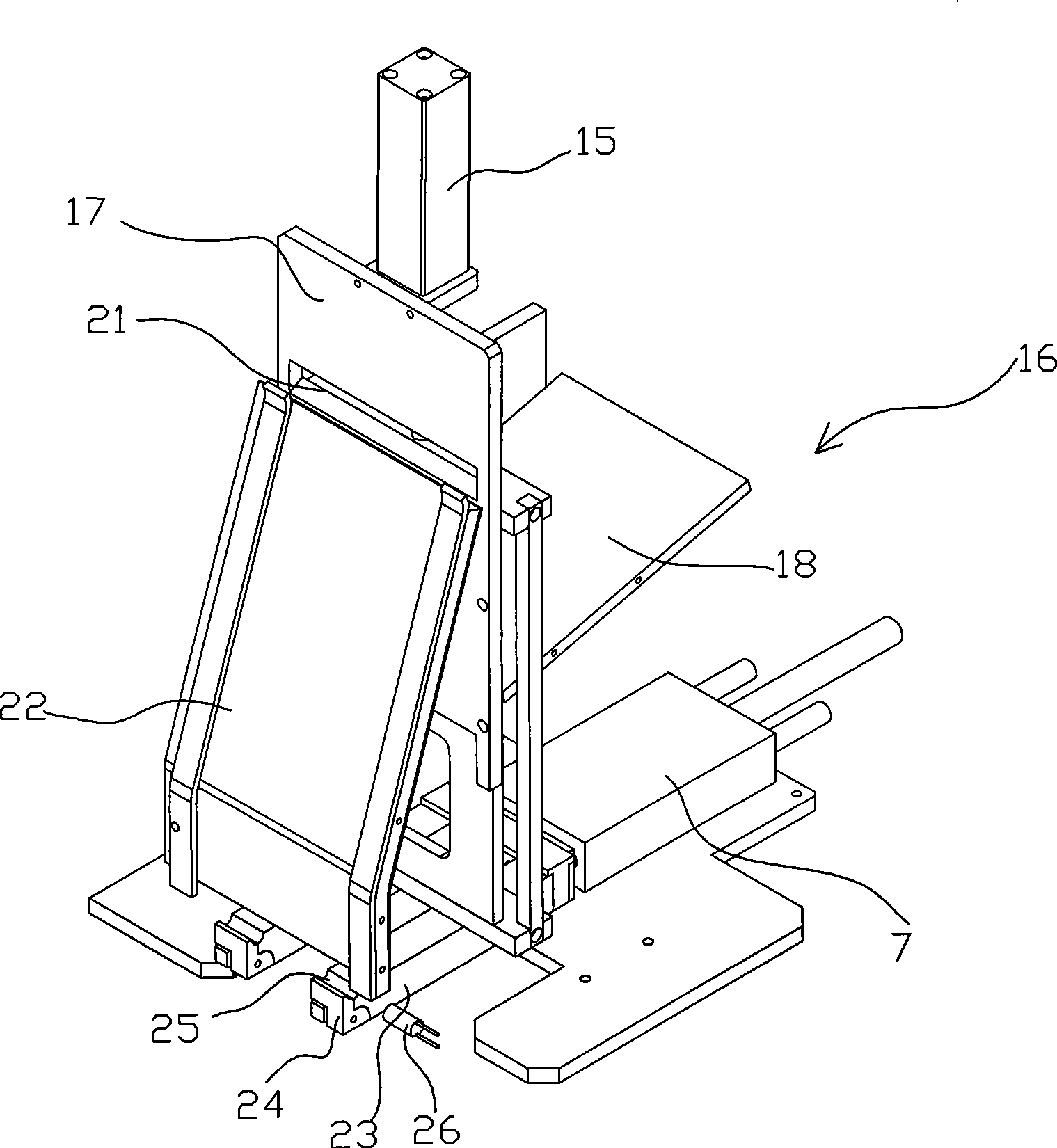

[0040] The feeding mechanism A is installed on the side of the lathe body close to the chuck part 2, so that it is convenient to load the shaft parts to be processed next to it, see Figure 1, 3-5, it includes a feeding rack 16, and the feeding rack 16 is installed There is a feeding cylinder 15, and the feeding cylinder 15 is on the outside of the slide plate 17. The feed rack 15 is obliquely provided with a feed plate 18 on the outside of the slide plate, and an opening for the L-shaped hanging plate 20 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com