Self-anchored rope-suspension bridge inclined drawing construction method

A self-anchored suspension bridge and construction method technology, applied in the direction of suspension bridges, bridges, bridge forms, etc., can solve the problems of bracket impact, high cost of brackets in water, brackets affecting navigation and flood discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

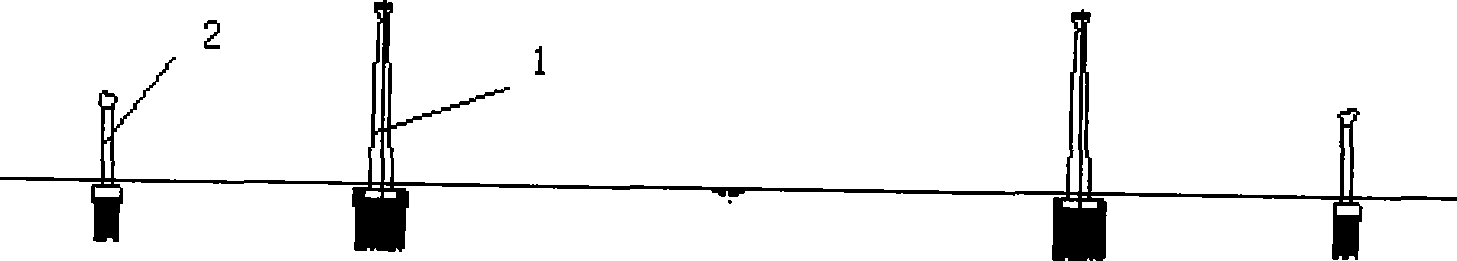

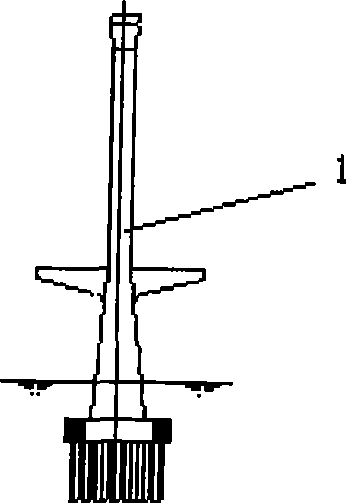

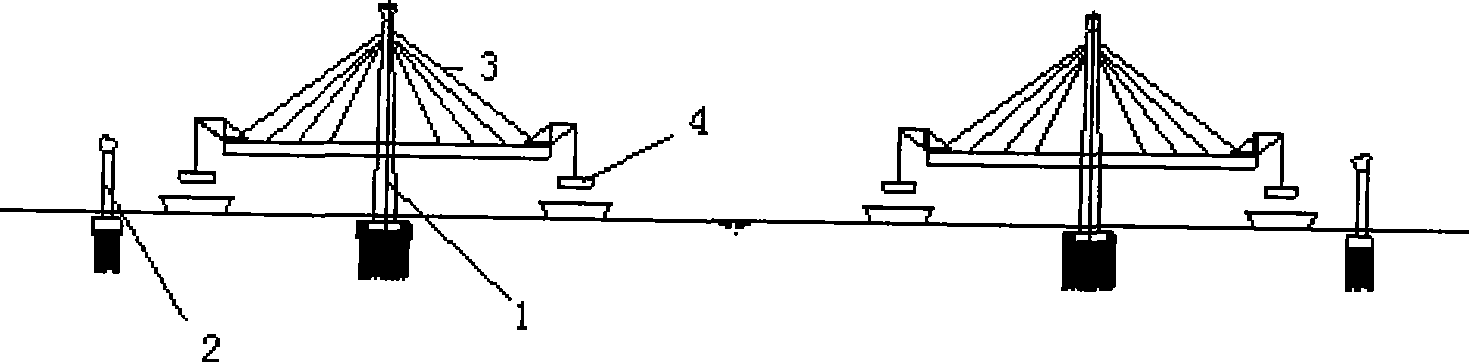

[0025] The construction schematic diagram of the present invention is shown in the figure. figure 1 For step A, use the permanent bridge tower of the self-anchored suspension bridge to carry out the foundation construction of the main tower 1 and the side pier 2, and make the main beam segment 4. image 3 with Figure 4 For step B, use the beam hoist to transport and lift the main beam section 4, adopt the method of tensioning the temporary stay cable 3, use the cable-staying method to assemble the main beam section 4 with symmetrical cantilever beams, and move from the main tower 1 to both sides one by one Assemble forward; Figure 5 with Image 6 In step C, the side spans are closed, that is, after assembling the main girder section 4 to the side pier 2, the main girder section 4 is assembled using a cable-stayed single cantilever until the middle span is closed, and finally the main girder 7 of the cable-stayed bridge is formed; Figure 7 ~ Figure 12 is step D, cable sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com