Supersonic speed combustion chamber burner scheme with novel injection structure

A technology of supersonic combustion chamber and combustion chamber, which is applied in the direction of combustion chamber, combustion method, continuous combustion chamber, etc., can solve the problems that have not been proposed, and achieve the effect of improving effective mixing and small total pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

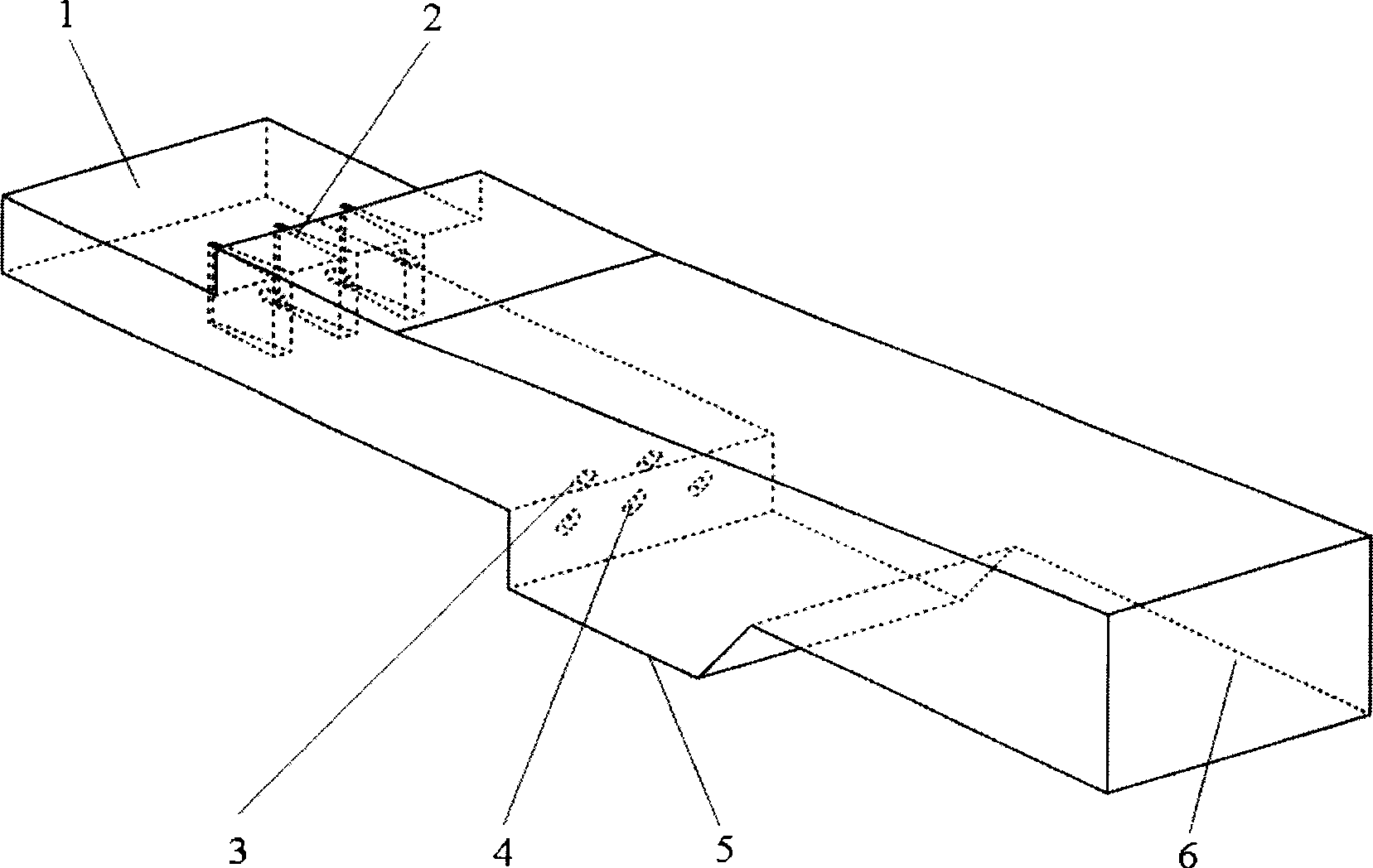

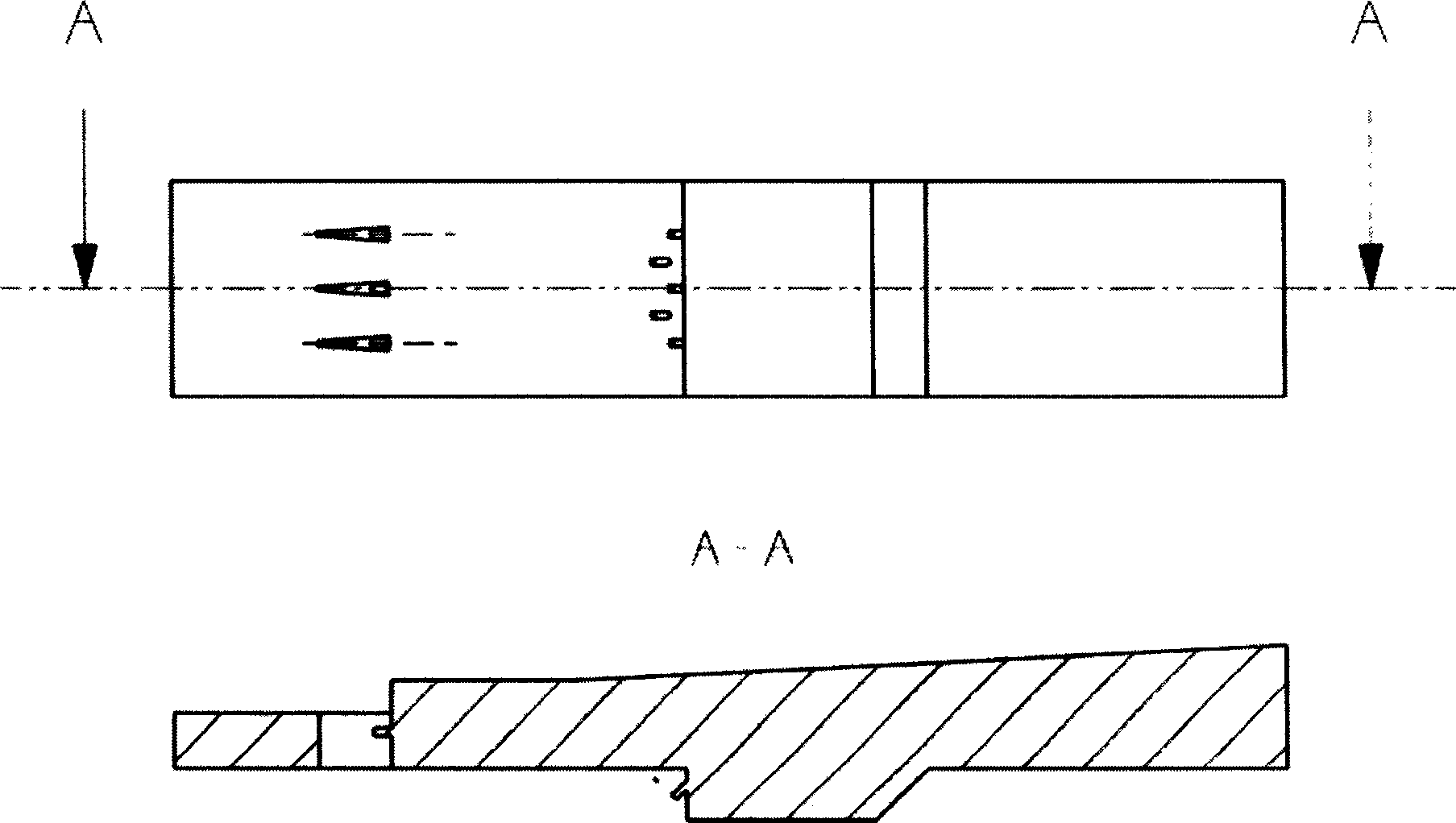

[0026] The specific implementation of the supersonic combustion chamber nozzle design scheme of the new injection structure proposed by the present invention can be carried out in the following design manner. When designing the actual combustion chamber structure, according to the specific design requirements, the layout positions of the groove, the groove front nozzle and the groove front wall nozzle can be appropriately modified, and after the simulation analysis is carried out with a certain numerical value, the fuel nozzle The design ideas and schemes are applied to the structural design of the supersonic combustion chamber. In this way, on the one hand, it can reduce the research and development expenses in the initial stage of the design work in the past; on the other hand, to a large extent, the weight of the supersonic ramjet engine can be reduced, the size of the final product can be reduced, and the maneuverability of the final power system product can be increased. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com