A new ignition system and ignition method for multiple ignition of liquid ramjet

A ramjet engine, multiple ignition technology, applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve the problems of poor maintainability, complex system, etc., achieve wall temperature reduction, simple system, and guaranteed reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

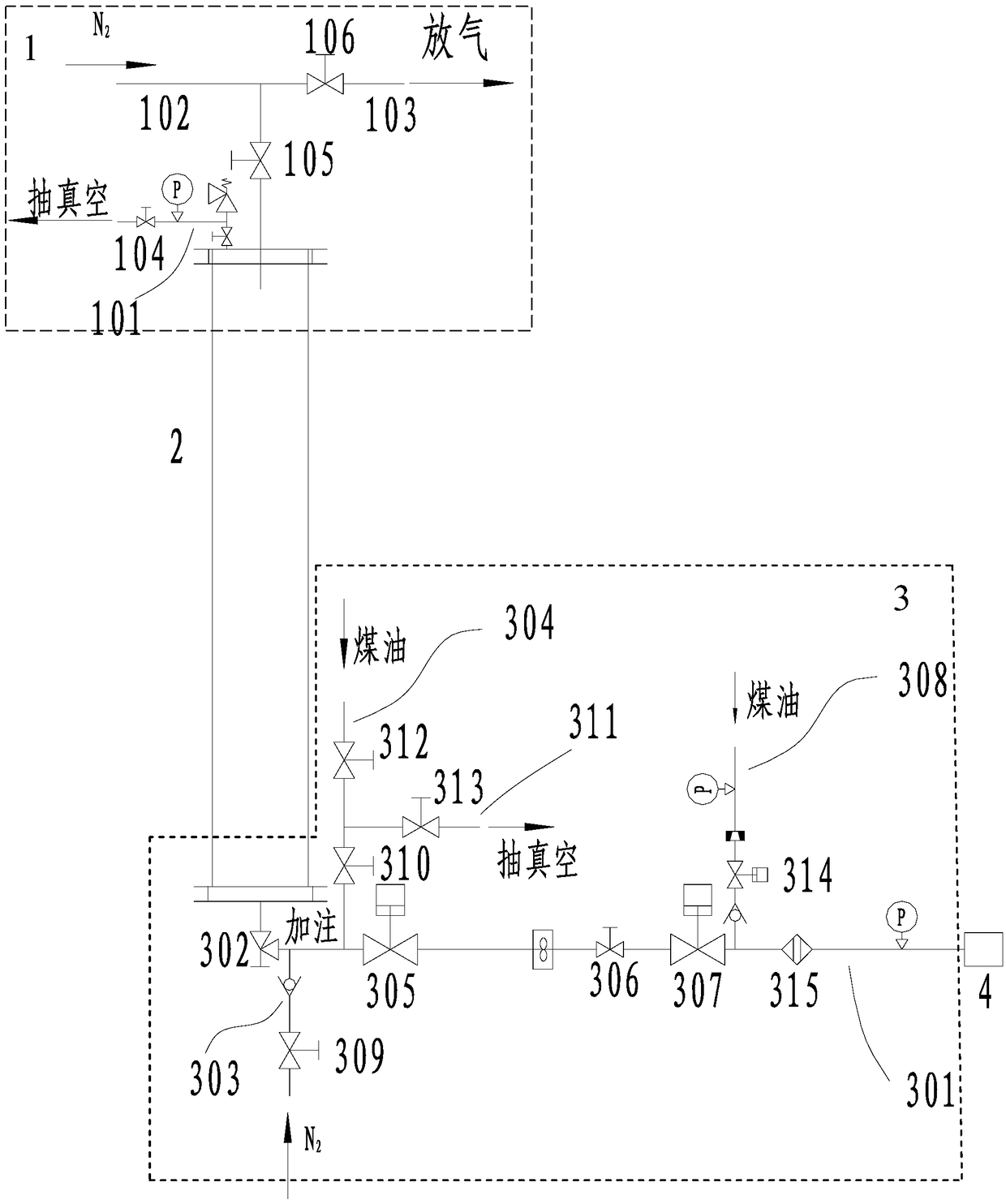

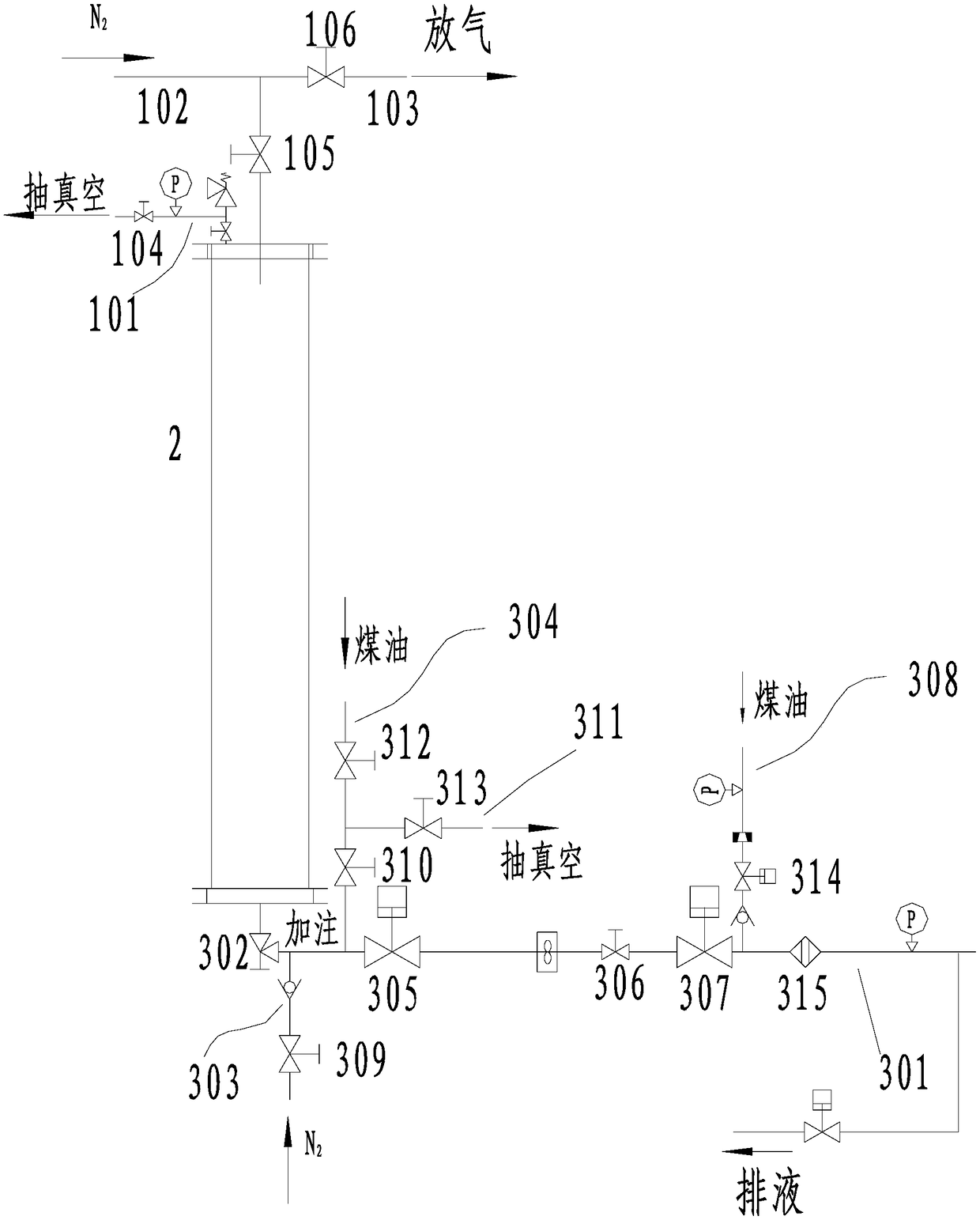

[0041] Such as figure 2 As shown, the novel ignition system disclosed by the present invention for multiple ignition of liquid ramjet includes a booster system 1 , an igniter storage tank 2 , a supply system 3 and an injector 4 connected in sequence.

[0042] The pressurization system 1 includes a first vacuum pipeline 101 and a pressurization pipeline 102 installed on the upper end of the igniter storage tank 2; , an exhaust pipeline 103 is reserved on the pressurization pipeline 102 . A first vacuum isolation valve 104 is provided on the first vacuum pipeline 101, a pressurized gas isolation valve 105 is installed on the pressurized pipeline 102, a pressurized gas replacement valve 106 is installed on the exhaust pipeline 103, and the aforementioned All valves are manual valves; along the exhaust gas flow direction, the exhaust pipeline is located at the rear end of the pressurized gas isolation valve.

[0043] The igniter storage tank 2 is used to store the igniter. Befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com