Ternary evaporator non-frost cold storage

An evaporator and cold storage technology, which is applied in the field of ternary evaporator frost-free cold storage, can solve the problems of decreased cooling effect, decreased humidity of the cold storage, and failure to achieve the cooling effect, so as to reduce defrosting operations, prevent liquid shock, reduce The effect of frosting phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

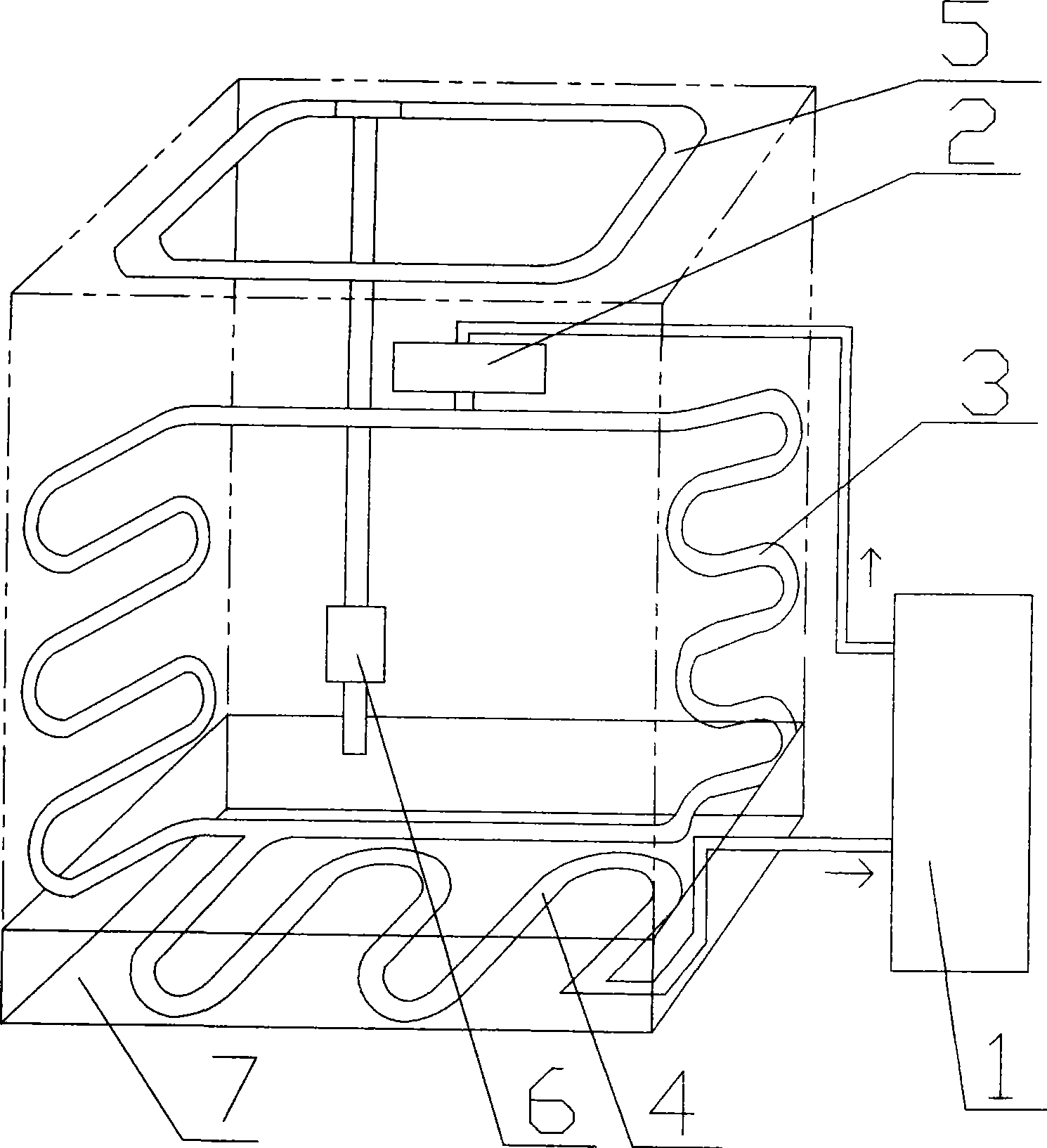

[0012] Accompanying drawing is an embodiment of the present invention, and it comprises compression refrigerating unit 1, air cooler 2, wall evaporating pipe 3 and the floor shallow pool 7 that is equipped with refrigerant at the bottom of the cold storage, the floor shallow pool 7 Evaporation pipe 4 etc. in the pool. A refrigerant is placed in the shallow pool 7 on the floor. The wall evaporating row pipe 3 is arranged on any other wall body or multiple walls except that the cooling fan is housed. The liquid outlet end of the compression condensing refrigeration unit 1 is connected to one end of the cooling fan 2, the other end of the cooling fan 2 is connected to the wall evaporation pipe 3, the other end of the wall evaporation pipe 3 is connected to the evaporation pipe 4 in the pool, and the evaporation pipe 4 in the pool The other end communicates with the steam return end of the compression condensing refrigeration unit 1 . The refrigerant first enters the cooling fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com