Spray cooling system for large-sized steam turbine air cooling heat radiator

An air-cooled radiator and spray cooling technology, which is applied in the field of cooling pipeline system, can solve the problems of limited load operation of steam turbine units, and the heat dissipation effect cannot meet the design requirements, and achieve the effect of improving operating economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

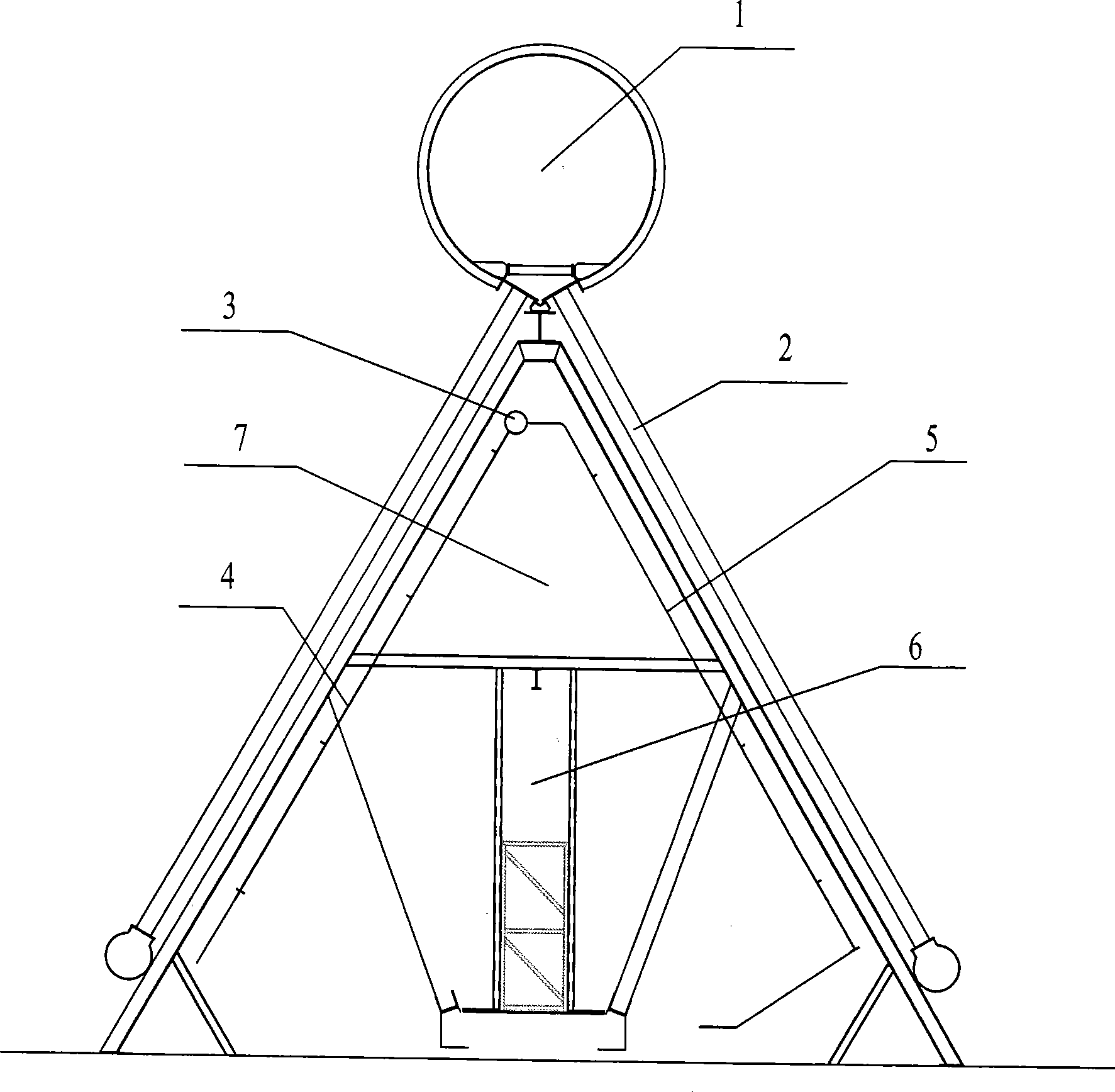

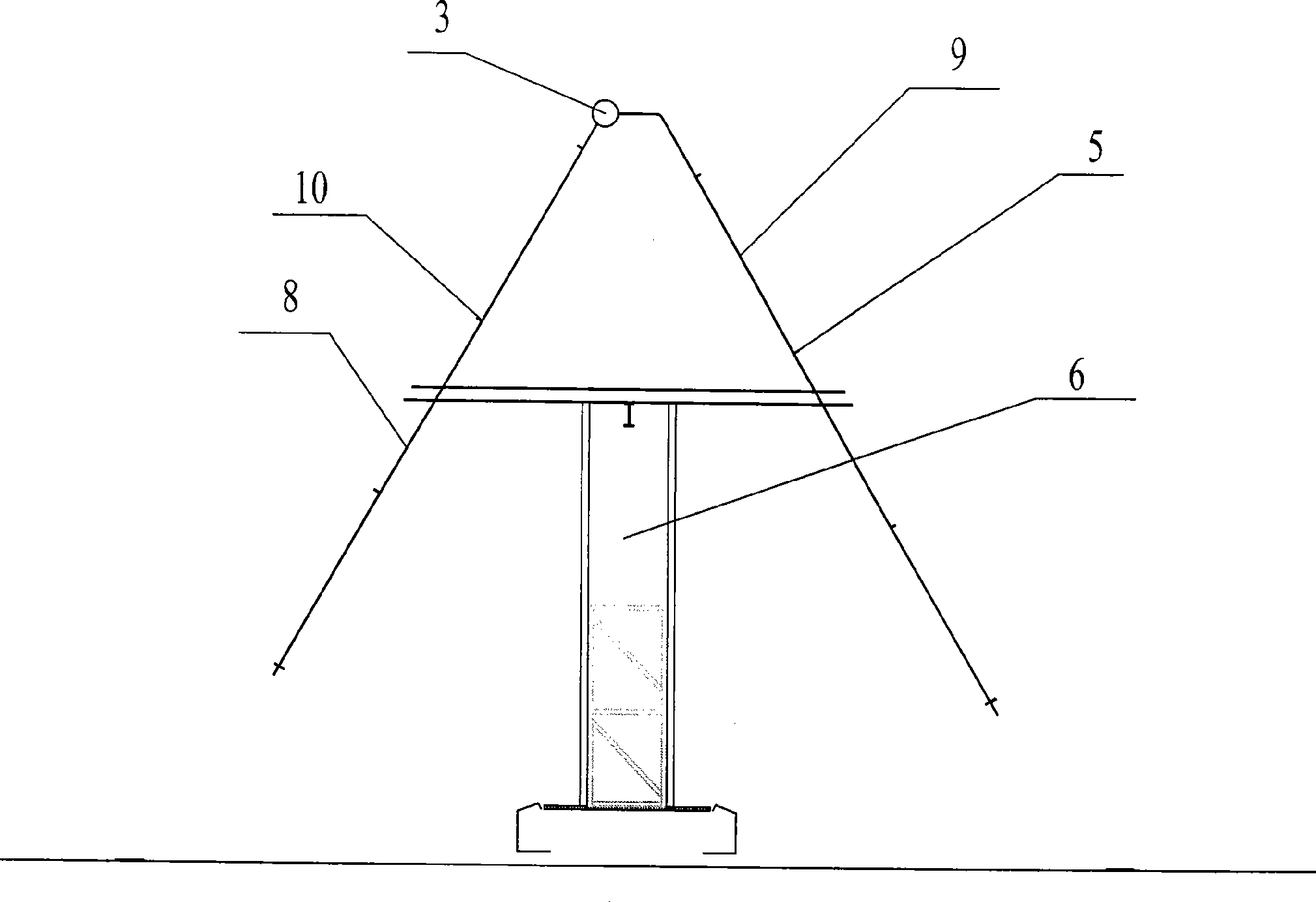

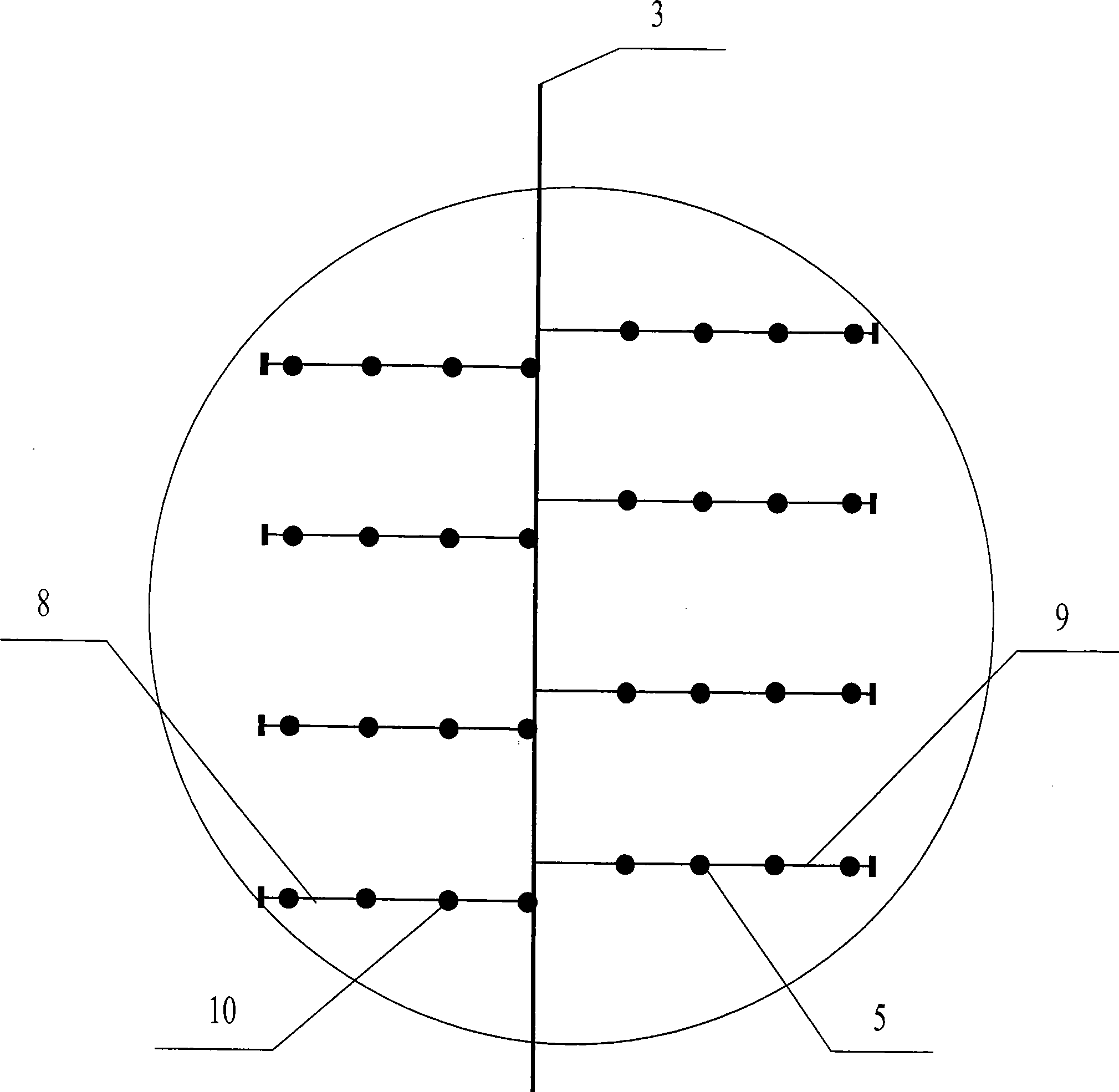

[0012] The spray cooling system for the air-cooled radiator of a large steam turbine includes a cooling water main pipe 3, a cooling water branch pipe 4 and a cooling water nozzle. The water right branch pipe 9, the cooling jellyfish pipe 3, one group of cooling water left branch pipe 8 and another group of cooling water right branch pipe 9 together form a triangular roof frame 7, which is arranged on the triangular cooling and heat radiation of the large steam turbine. In the unit 2, the cooling jellyfish pipe 3 is arranged at the top beam of the triangular roof frame body 7, a group of cooling water left branch pipes 8 is arranged at the left rafter beam position of the triangular roof frame body 7, and another group of cooling water right branch pipes 9 Set at the right rafter beam position of the triangular roof frame body 7, the upper ends of a group of cooling water left branch pipes 8 communicate with the cooling jellyfish pipe 3, the lower ends of a group of cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com