Method for manufacturing flexible printed circuit board and detection method thereof

A flexible printing and inspection method technology, applied in the directions of printed circuit manufacturing, printed circuits, circuit inspection/monitoring/correction, etc., can solve the problems of not being able to obtain stable inspection quality, reducing the reliability of electrical inspection, increasing production costs, etc. Check performance, improve competitiveness, reduce the effect of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Various modifications are possible for the embodiments of the present invention, and the scope of the present invention is not limited to the embodiments described below. The embodiments of the present invention are intended to provide more sufficient explanations to those skilled in the art. Therefore, the shapes and the like of the components in the drawings are exaggerated for further emphasis.

[0043] Refer below Figure 1 ~ Figure 1 0 The embodiments of the present invention will be described in detail.

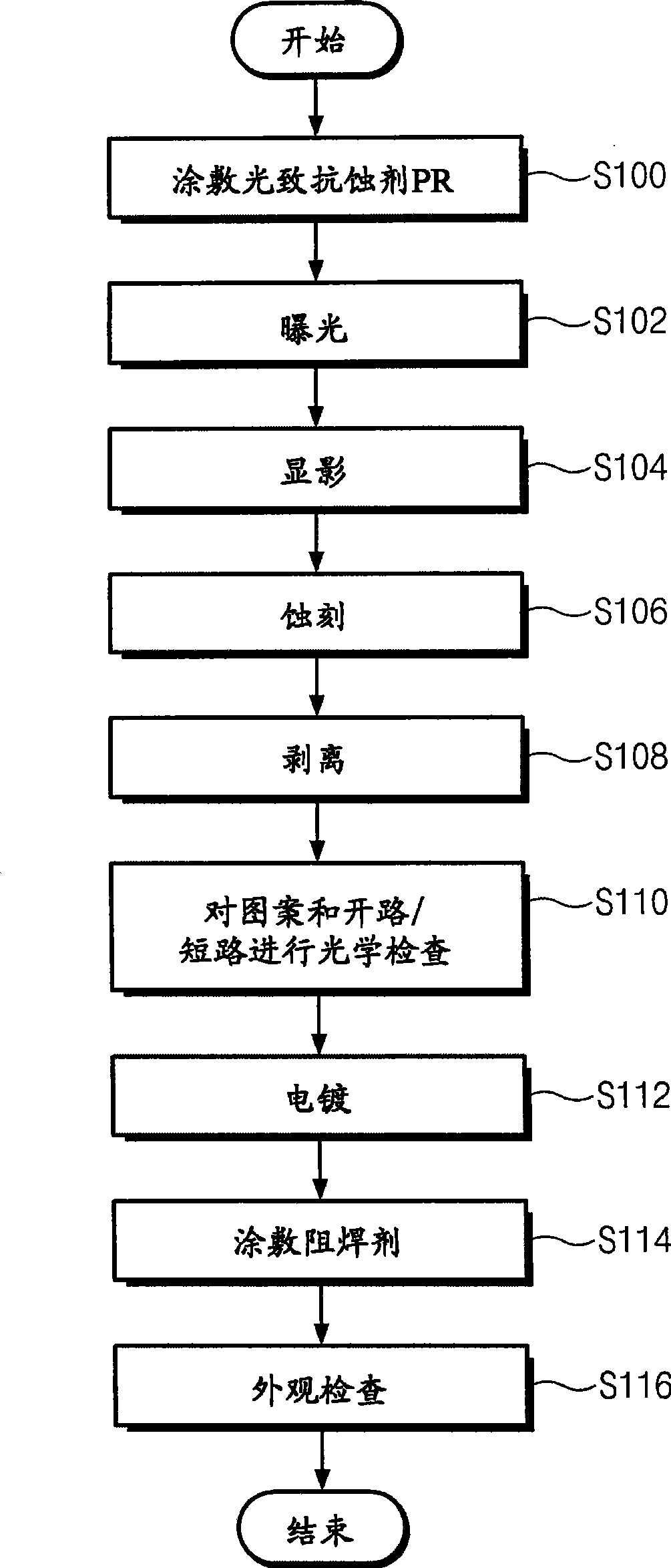

[0044] figure 1It is a flowchart showing the manufacturing procedure of the flexible printed circuit board for a display driver chip having an ultrafine circuit pattern of the present invention.

[0045] Such as figure 1 As shown, the manufacturing sequence of the flexible printed circuit board of the present invention is as follows: in step S100, a photoresist is coated on the base plate provided with copper foil, and in step S102 and step S104, exposure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com