Structure optical parameter demarcating method based on one-dimensional target drone

A structured light and target technology, applied in the field of measurement, can solve the problems of increased cost, limited processing size of high-precision two-dimensional and three-dimensional targets, and difficulty in guaranteeing the processing accuracy of two-dimensional and three-dimensional calibration targets, and achieves low cost and simple structure. , Reduce the effect of parameter calculation link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

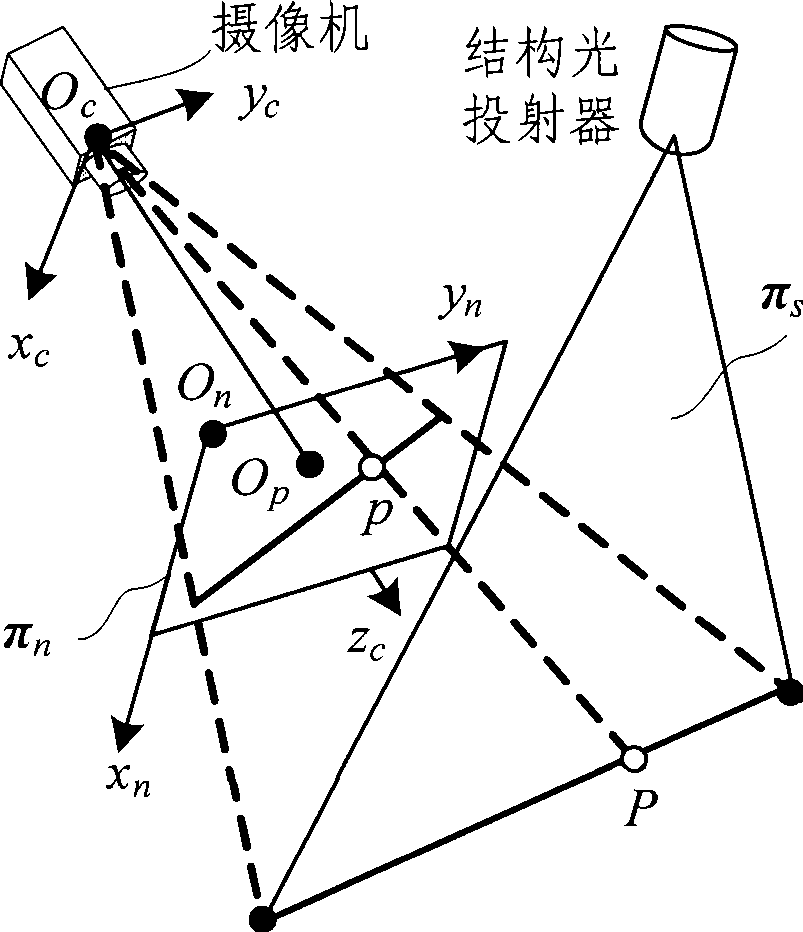

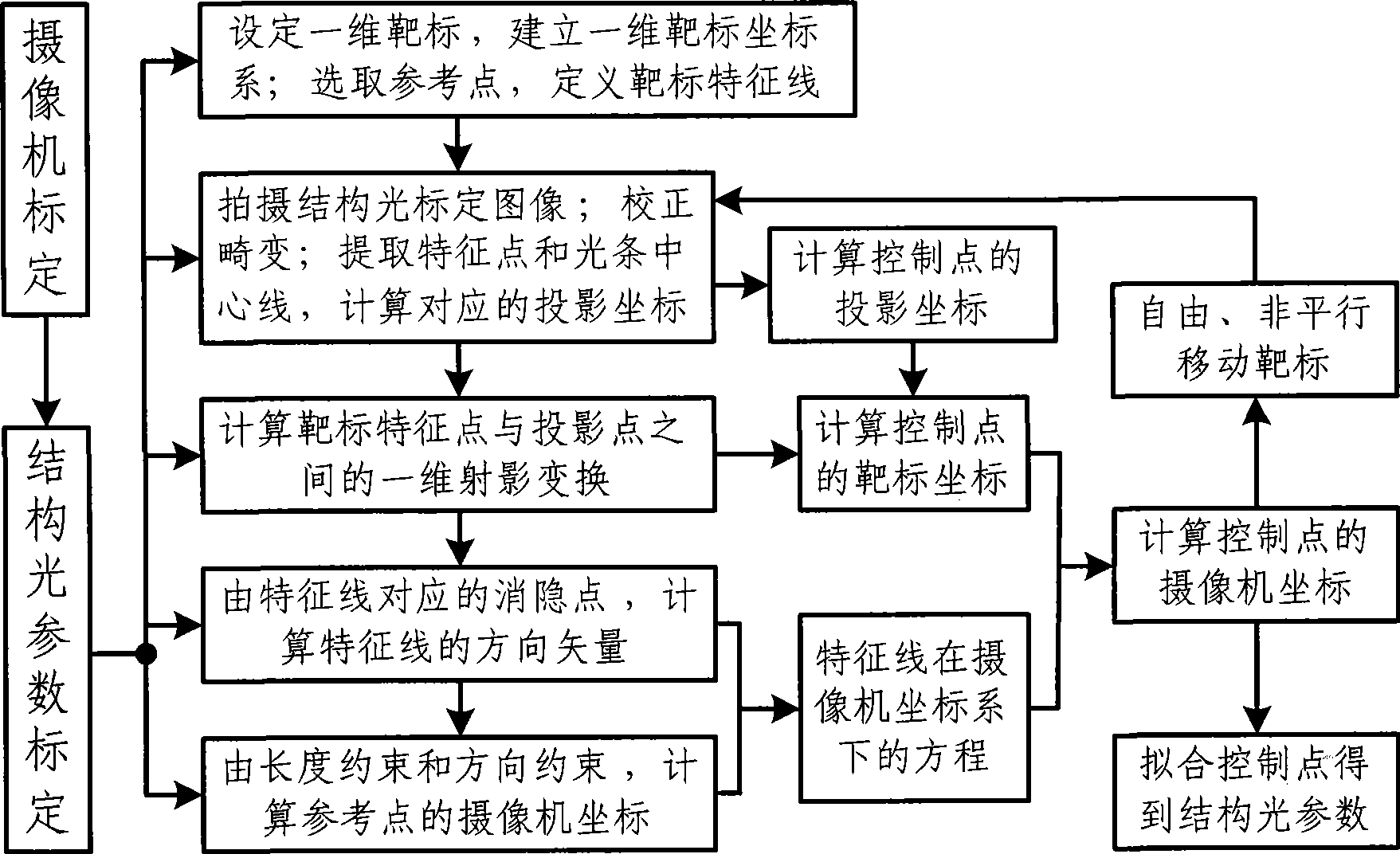

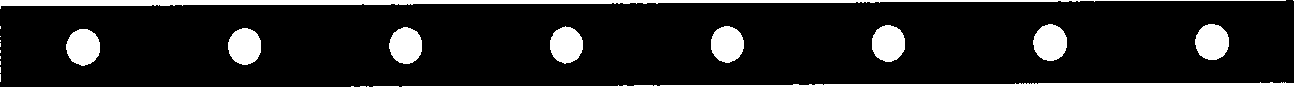

[0071] The process of the structured light parameter calibration method based on the one-dimensional target is as follows: figure 2 shown. WAT-902HCCD camera and 12mm lens are used to form a lens and a structured light projector to form a structured light vision sensor, and the image resolution is 768pixels×576pixels. One-dimensional targets can be designed as image 3 As shown, the center point of the white circle in the figure is the target feature point. The distance between target feature points is 14mm, and 8 feature points are set.

[0072] In order to facilitate the comparison test, a printed two-dimensional checkerboard target is used. The feature points on the target are 6×8 grid points, and the distance between the grid points is 14mm. Figure 4 image for the experiment. According to the planar target calibration method with constant cross ratio, 6 control points can be obtained for each image. image 3 Each row of the shown two-dimensional target is equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com