Anode component for X ray tube

A technology for anode components and light tubes, which is applied to X-ray tube parts, X-ray tube electrodes, bearing components, etc., can solve the problem that the service life of movable parts cannot be guaranteed, and the coordination relationship cannot be well coordinated. X-ray tube anode vibration and noise problems, to achieve the effect of attenuating vibration, ensuring stability, and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

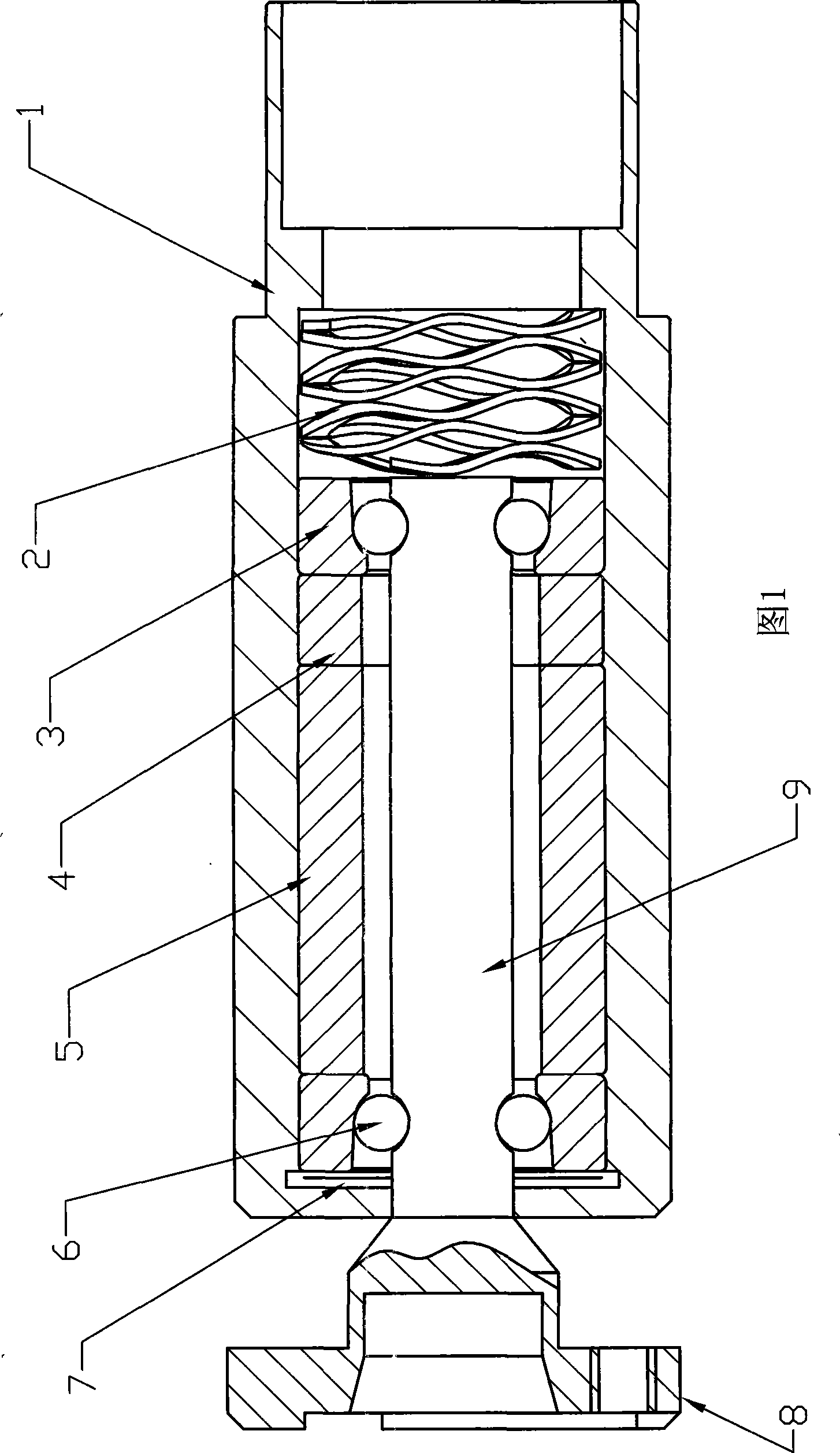

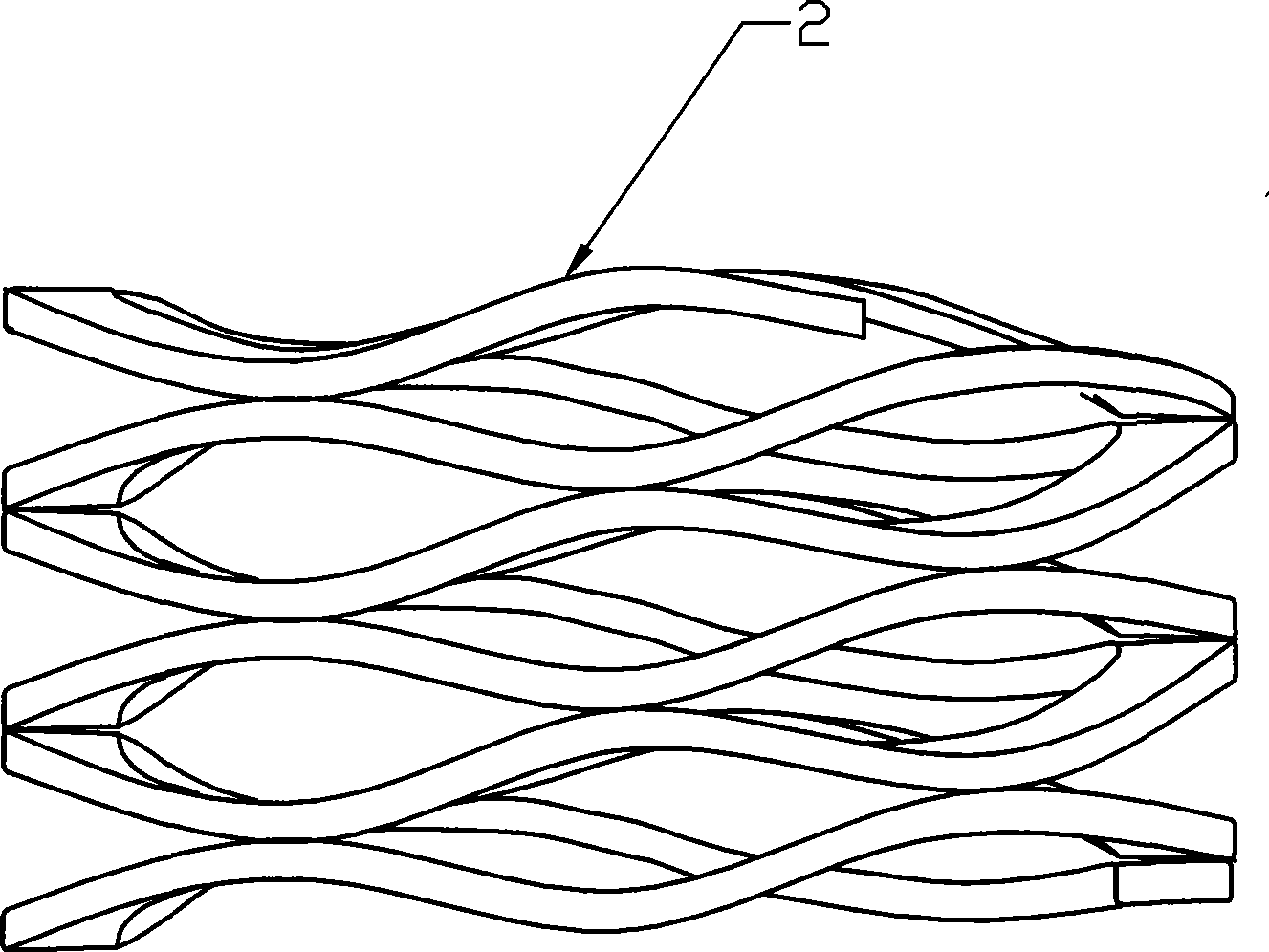

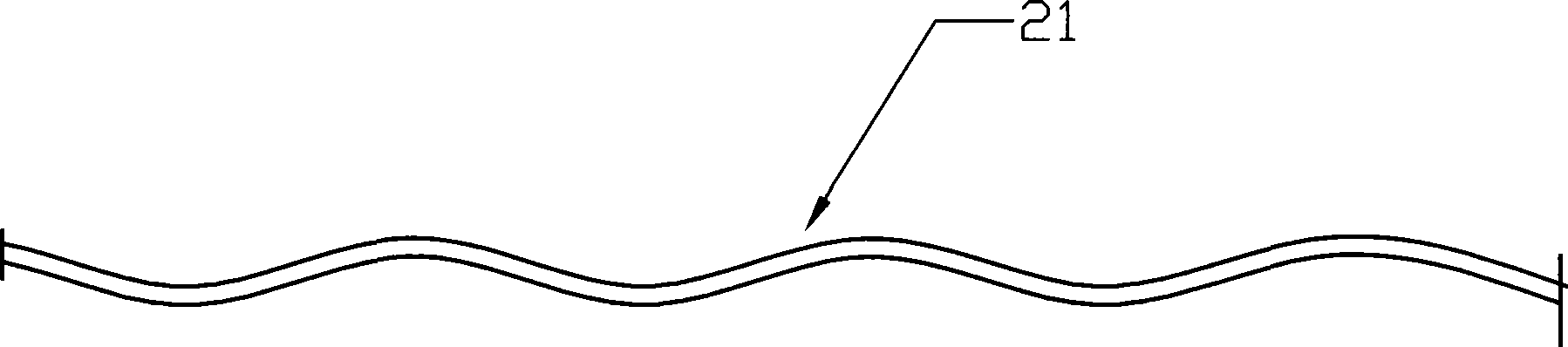

[0023] See accompanying drawings 1, 2, 3, 4, 5, 6, the anode assembly in the X-ray tube of the present invention comprises a hollow anode rod body 1, an outer ring 3, a ball 6 and a connecting shaft 9, and the outer ring 3 is sleeved on the connection On the outer side of the shaft 9 , the outer peripheral surface of the connecting shaft 9 is provided with a channel 10 corresponding to the outer ring 3 , and the ball 6 is located between the outer ring 3 and the channel 10 .

[0024] There are two outer rings 3, and a cylindrical support sleeve 5 and a C-shaped loading adjustment ring 4 are sleeved between the two outer rings 3 on the connecting shaft 9. The two outer rings 3 and the support sleeve 5, The C-shaped loading adjustment rings 4 are axially stacked together.

[0025] One end of the connecting shaft 9 is located in the anode rod body 1, and the other end extends to the outside of the anode rod body 1, and a connecting flange 8 is connected to the protruding end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com