CMOS image sensor device and its formation method

An image sensor and pattern technology, which is applied in radiation control devices, electric solid devices, semiconductor devices, etc., can solve the problems such as the inability of the lens to focus, achieve the effect of optimizing the sensitivity and improving the forming method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

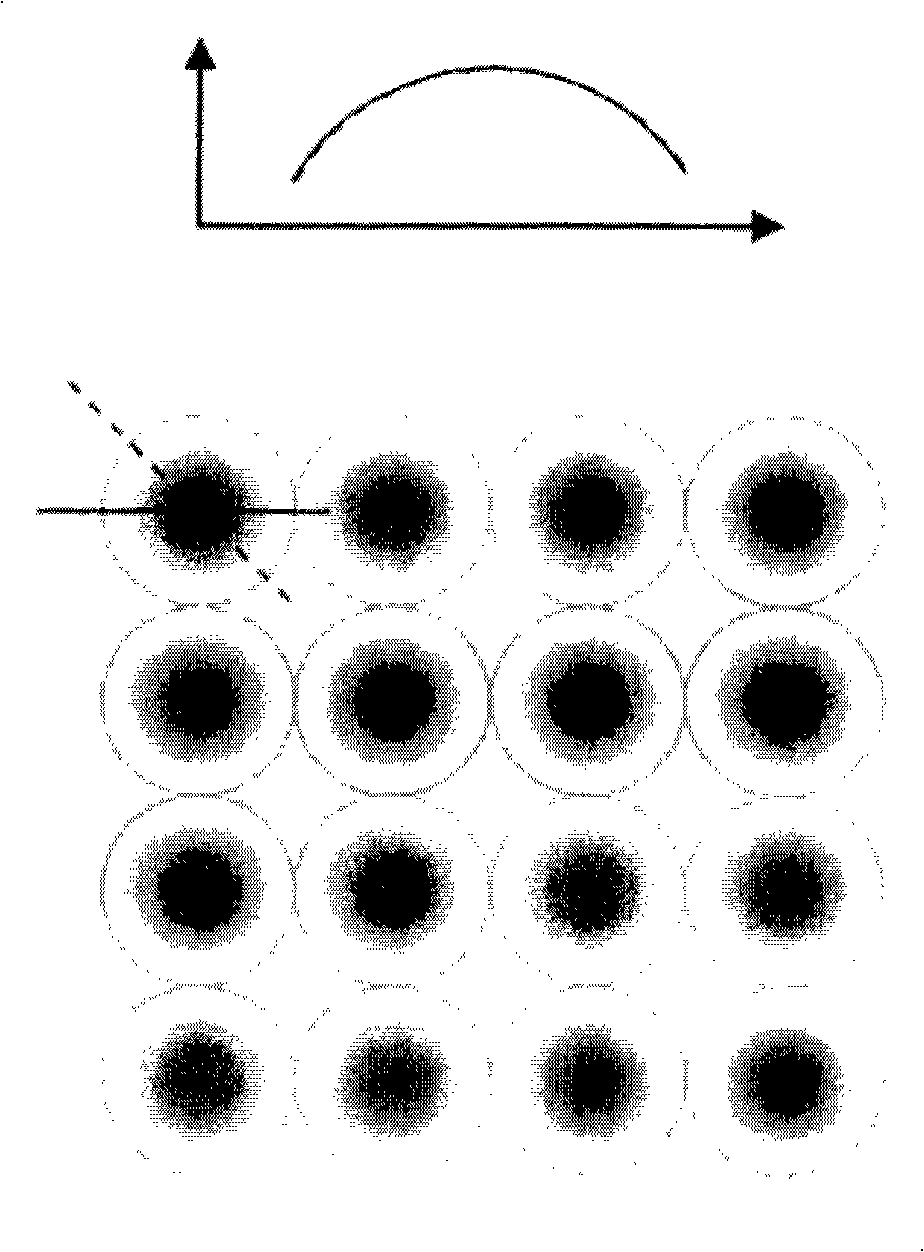

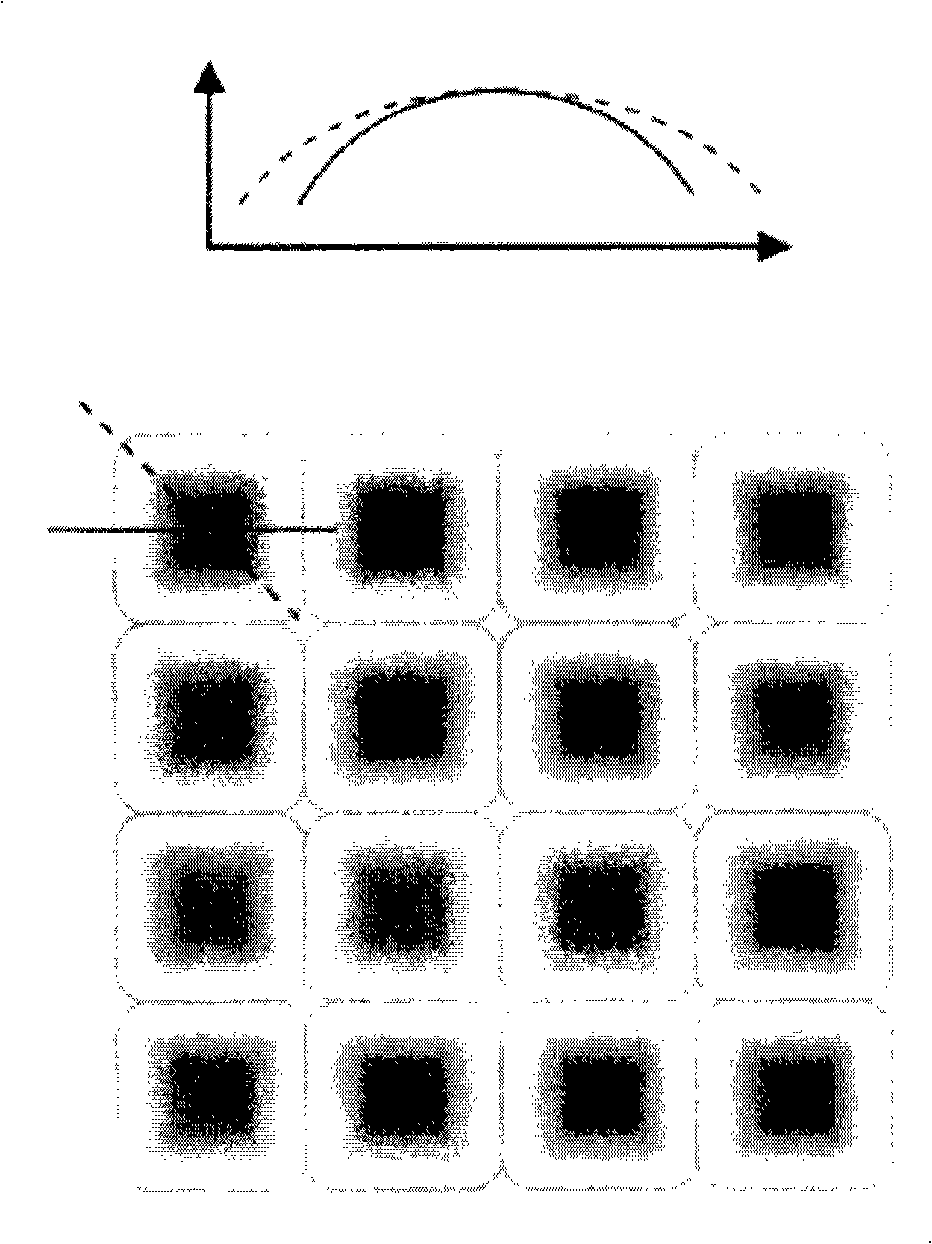

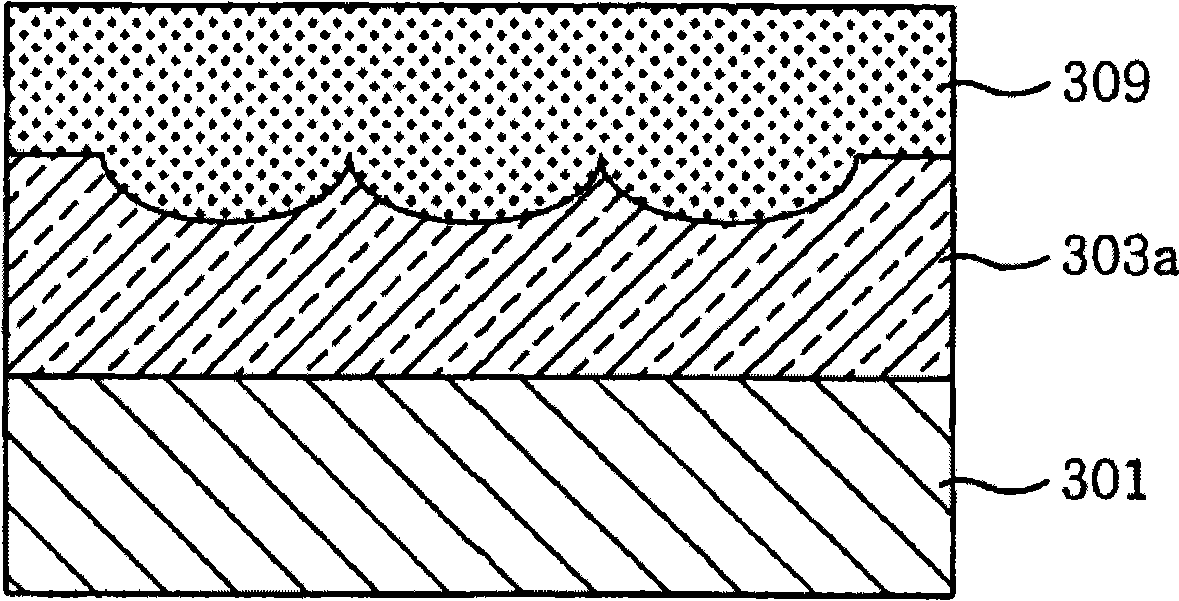

[0018] example figure 2 is a view showing the structure of a CIS device according to an embodiment of the present invention. A photoresist (hereinafter, PR) is coated over the entire surface of the top of the logic part 301 including a photodiode over the semiconductor substrate. Then, a barrier layer for forming an MLA pattern and a PR pattern are sequentially formed over the entire surface of the PR top. The MLA pattern is formed by performing an etching process to selectively remove the barrier layer deposited over the entire surface. The MLA PR pattern 303a is formed by performing isotropic etching using the PR pattern as a mask and then using the MLA pattern as a mask.

[0019] Next, an MLA having a concave structure may be manufactured by filling the material 309 into the entire surface of the top of the MLA PR pattern 303a and performing a planarization process. Material 309 has a refractive index n 2 Higher than the refractive index of the MLA PR pattern 303a.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com