Laminated flexible resilient abrasive article

An abrasive product, abrasive technology, applied in the field of flexible elastic sheet abrasive products, sanding tool components, can solve the problems of short life, difficult to grasp, control and operate, achieve low cost, improve flexibility, reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

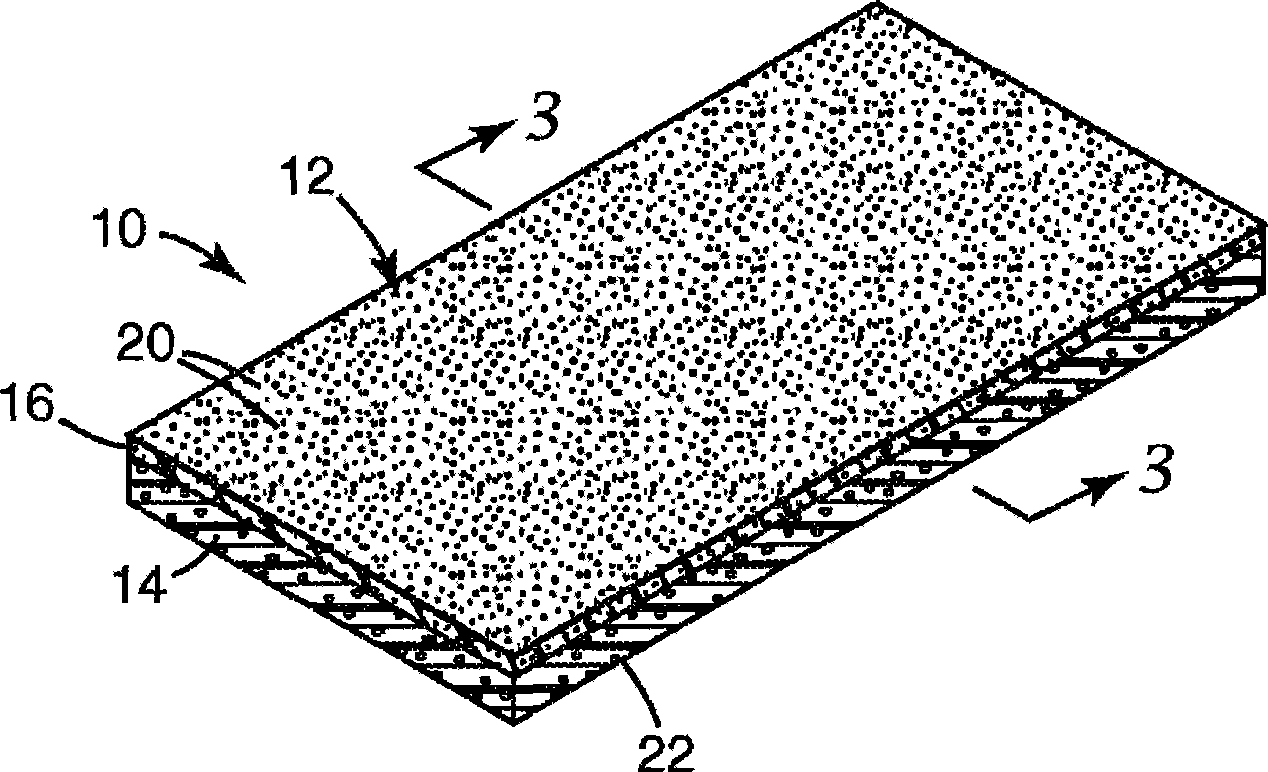

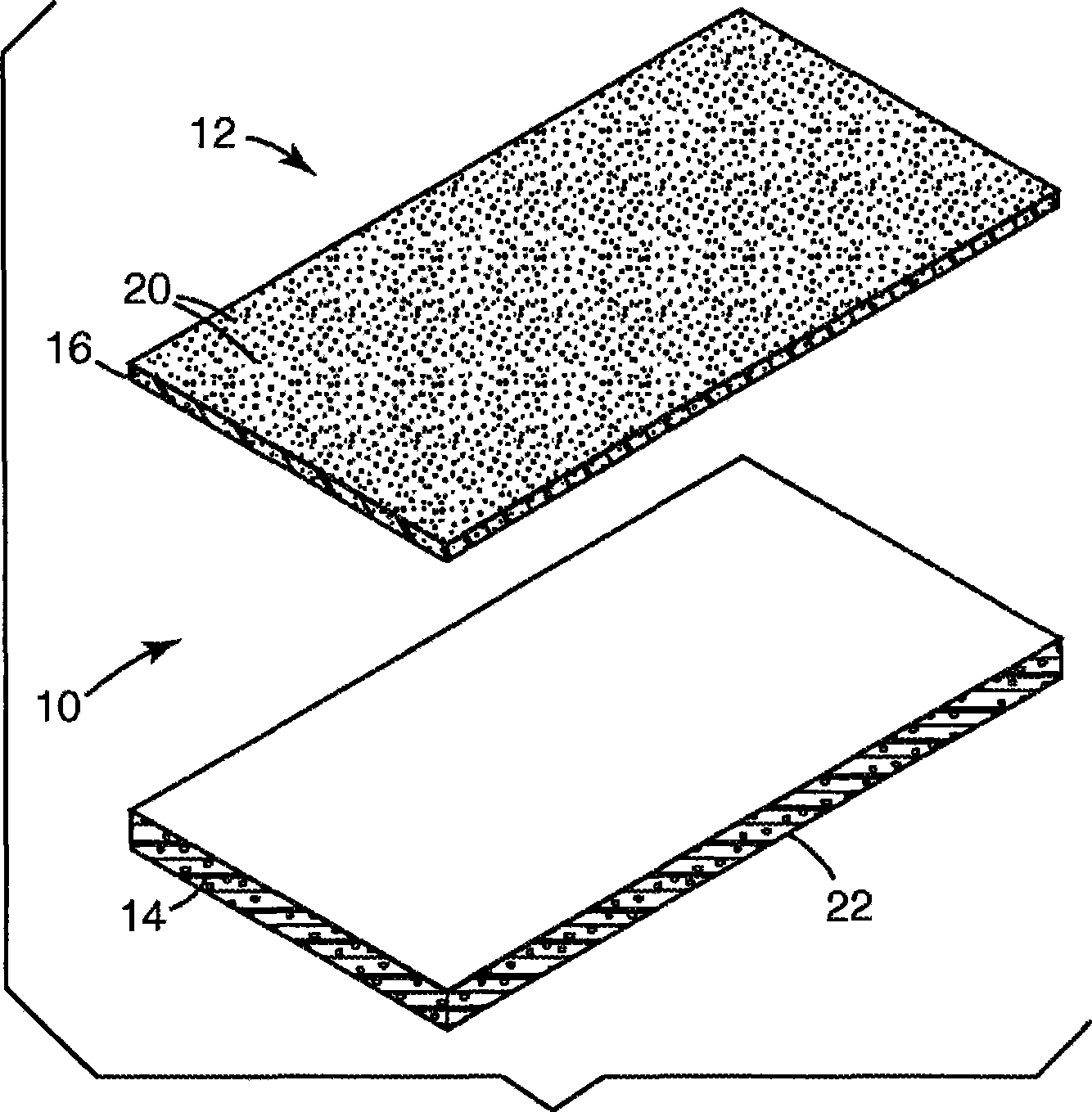

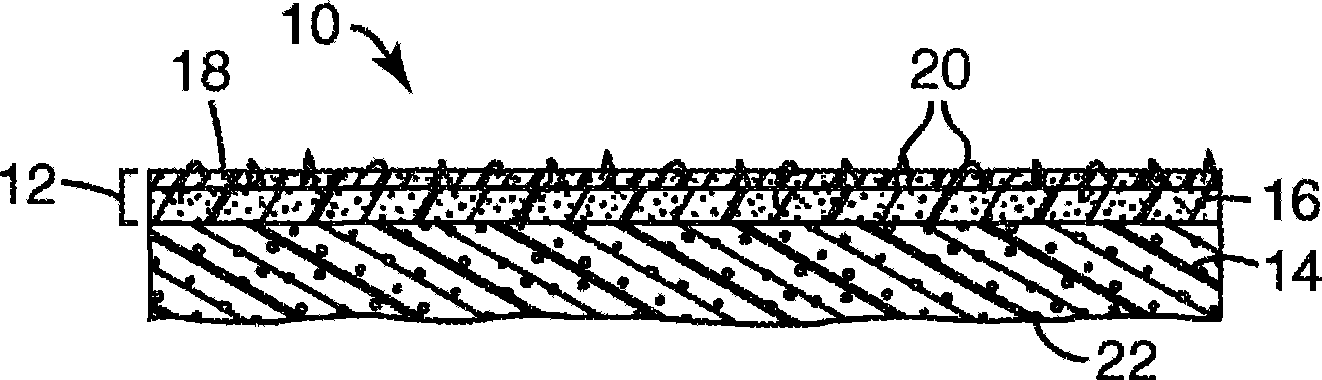

[0026] Referring now to the drawings, in which like reference numerals indicate like or corresponding parts throughout the several views, Figure 1-3 A pliable resilient abrasive article 10 comprising an abrasive sheet 12 and a backing sheet 14 is shown. The abrasive sheet 12 includes an abrasive support layer 16 attached to a backing sheet 14, an integral coating 18 ( image 3 ) on the abrasive support layer 16, and a plurality of abrasive particles 20 at least partially embedded in the integral coating 18. The abrasive support layer 16, integral coating 18 and abrasive grains 20 included in the abrasive sheet 12, and the backing sheet 14 are described in detail below.

[0027] Backing sheet 14

[0028] The backing sheet 14 is formed from a durable elastic conformable material. The backing sheet 14 provides a comfortable gripping surface for the user and also provides a degree of conformability to the abrasive article whereby the abrasive article 10 can more effectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com