Circuit connecting adhesive film, circuit member connecting structure and circuit member connecting method

A technology for circuit connection and circuit components, applied in the field of adhesive film for circuit connection, which can solve the problems of inability to maintain the insulation of adjacent electrodes, insufficient number of contact points, high resolution of difficult adhesives, etc., and achieve excellent long-term connection reliability, Excellent high resolution and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Acrylic particle-containing resin (acrylic particle-containing resin ( Nippon Shokubai Co., Ltd., trade name: BPA328) 10 parts by mass, bisphenol A solid epoxy resin (manufactured by Yuka Shell Epoxy Resin Co., trade name: YL980) 20 parts by mass, imidazole-based curing agent (manufactured by Asahi Kasei Kogyo Co., Ltd. , product name: NOVACURE HX-3941) 35 parts by mass and silane coupling agent (manufactured by Japan Unica Co., Ltd., product name: A187) 3 parts by mass, dissolved in toluene as a solvent to obtain an insulating property of 50 mass % of solid content A coating solution for forming an adhesive layer.

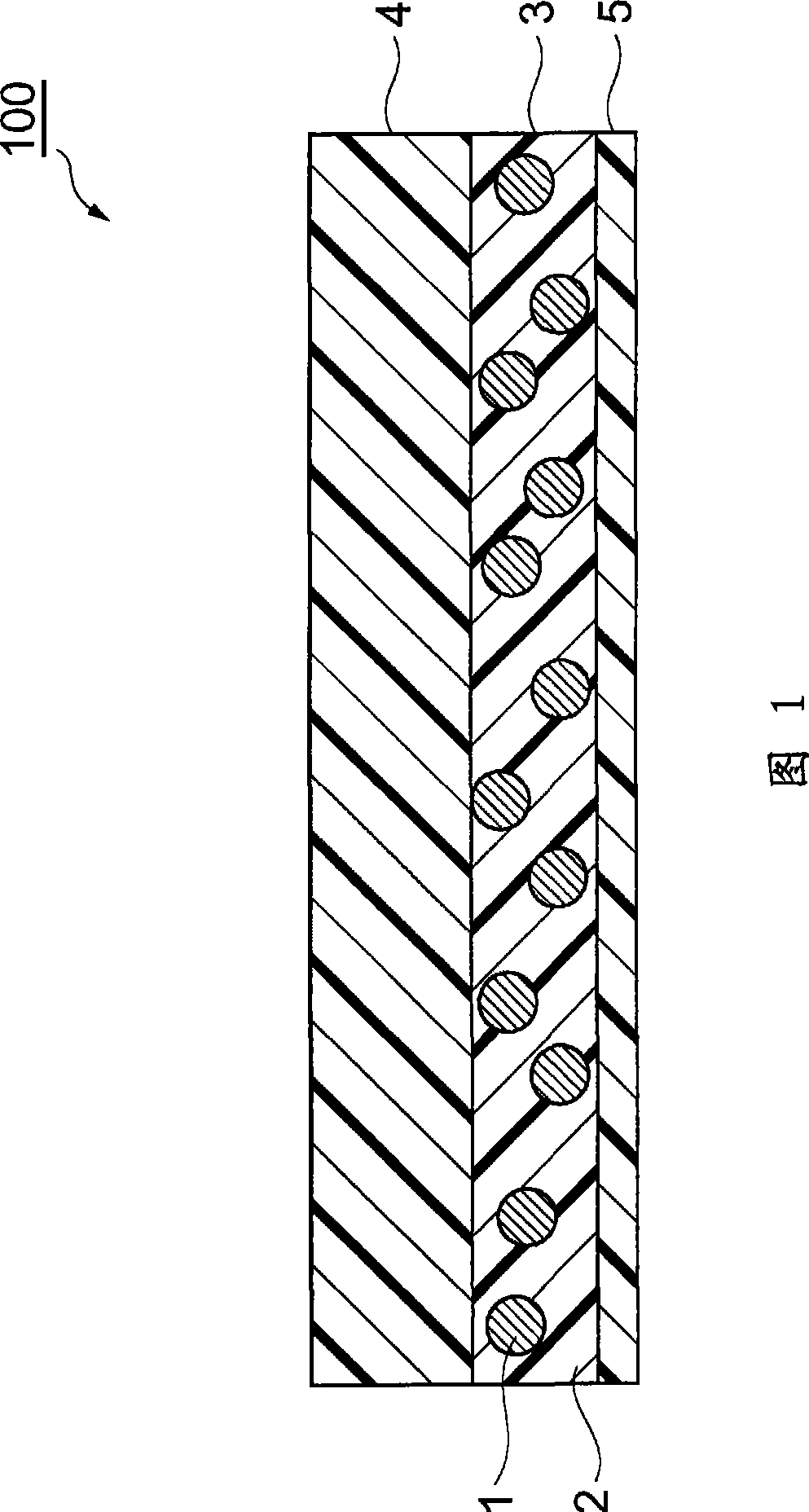

[0078] Next, using a coating device, the coating solution was applied to a PET film with a thickness of 50 μm that had been subjected to mold release treatment on one side (the surface on which the coating solution was applied), and dried with hot air at 70° C. for 10 minutes, thereby An insulating adhesive layer (a) having a thickness of 11 μm was formed ...

Embodiment 2

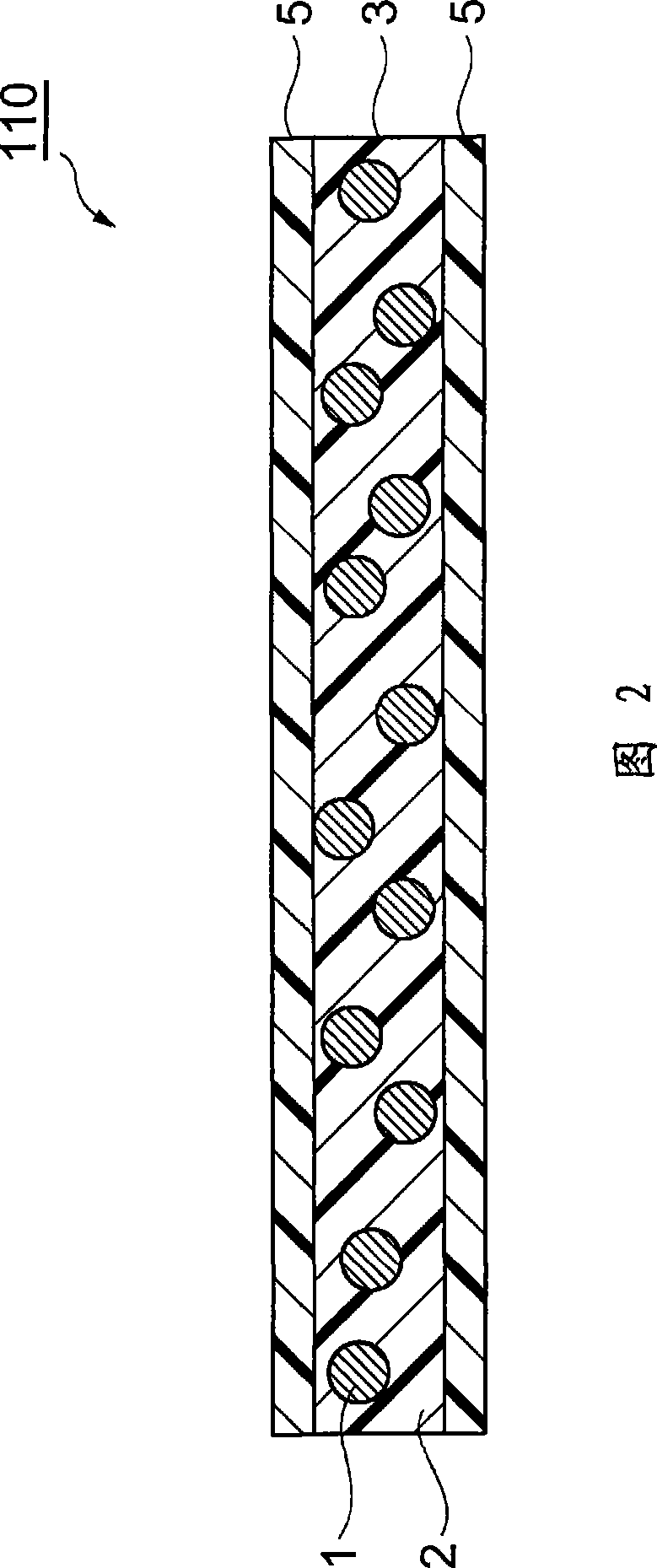

[0084]In addition to making the thickness of the insulating adhesive layer (a) 8 μm, making the thickness of the insulating adhesive layer (b) 5 μm, and further making the thickness of the conductive adhesive layer (c) 10 μm, It carried out similarly to Example 1, and obtained the adhesive film for circuit connections of a 3-layer structure.

Embodiment 3

[0086] The thickness of the insulating adhesive layer (a) is 12 μm, the thickness of the insulating adhesive layer (b) is 0.1 μm, and the thickness of the conductive adhesive layer (c) is 10 μm. , and in the same manner as in Example 1, an adhesive film for circuit connection with a three-layer structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com