Wire restoring device

A technology of a wire take-up and a wire take-up frame is applied in the field of wire take-ups, which can solve the problems of inconvenient air rope retraction, waste of a long time, low work efficiency, etc., and achieves a simple structure, improved work efficiency and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

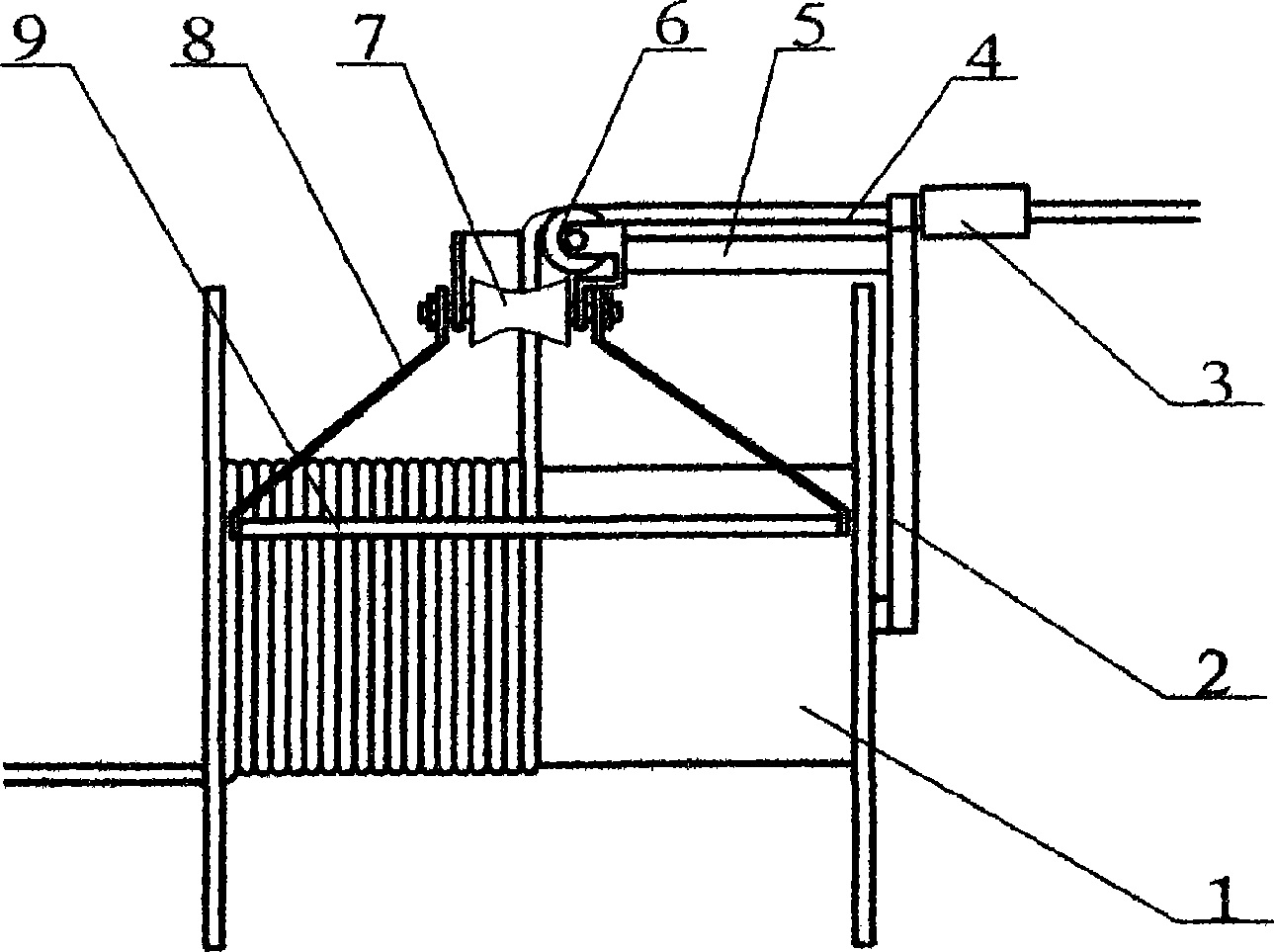

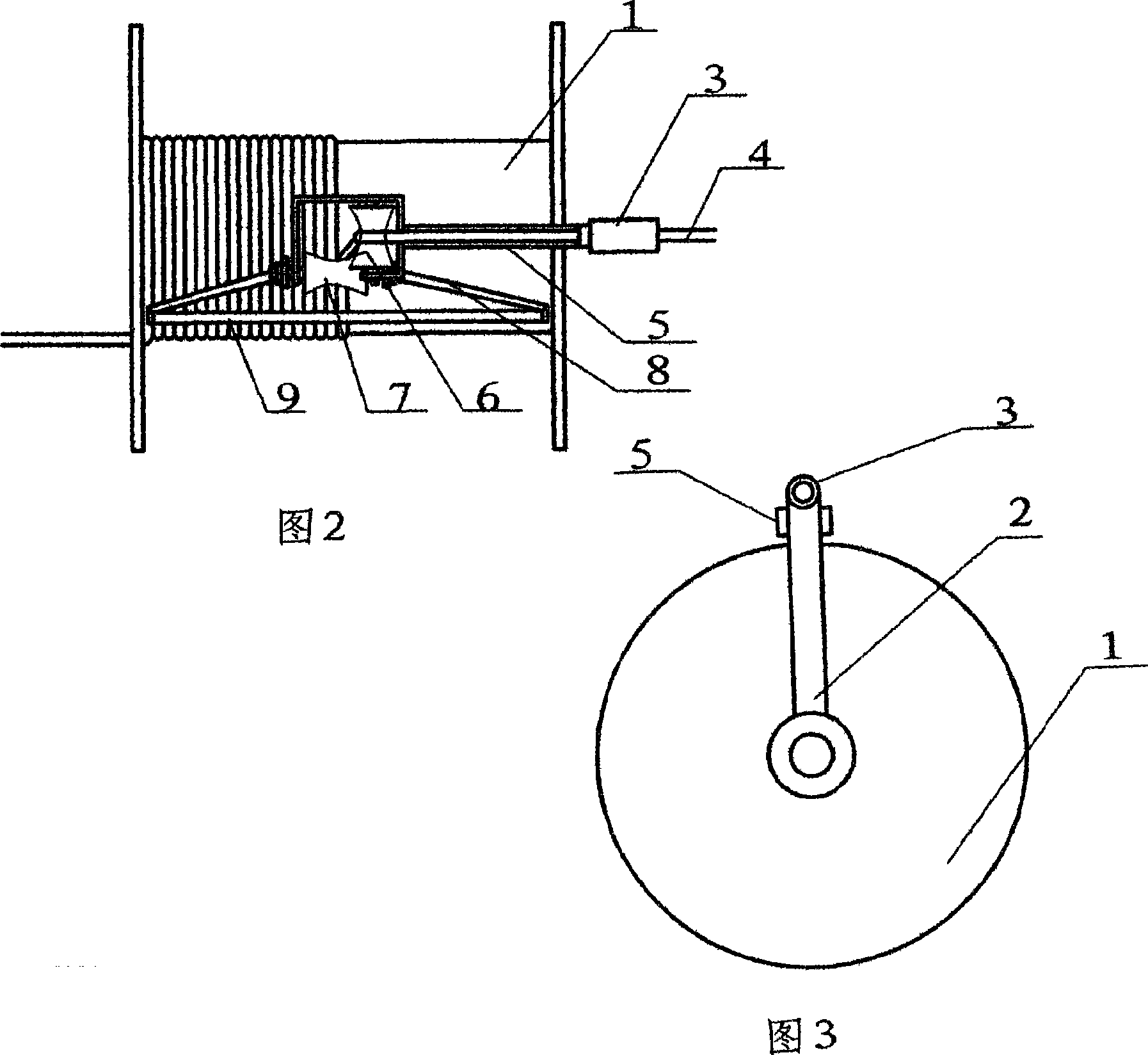

[0013] When the present invention is in use (taking the welding handle wire as an example), the wire take-up device is fixed on a suitable position of the electric welding machine, and one end of the welding handle wire (4) is passed through the hollow handle (3) through the wire take-up wheel (6) by the flat wire The roller (9) presses it, and then passes through the wire hole on the winding wheel (1) and fixes it on the terminal of the electric welding machine. At this time, shake the handle (3) and the wire take-up frame (5) to make a circular motion, and the wire can be welded Rewind on the reel (1); lift the flat roller (9) when unwinding, pull the welding handle wire (4) at the hollow handle (3), and reverse the take-up frame (5) under the action of tension With a circular motion, the thread can be released.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com