Soldered ball surface defect detection device and method based on machine vision

A defect detection and machine vision technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of ineffective detection of solder ball surface defects, affecting chip quality, and high false detection rate, and achieve accurate detection of solder ball surface defects. , the device structure is simple, the effect of strong classification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operating procedures are given, but the scope of protection of the present invention is not limited to the following Mentioned examples.

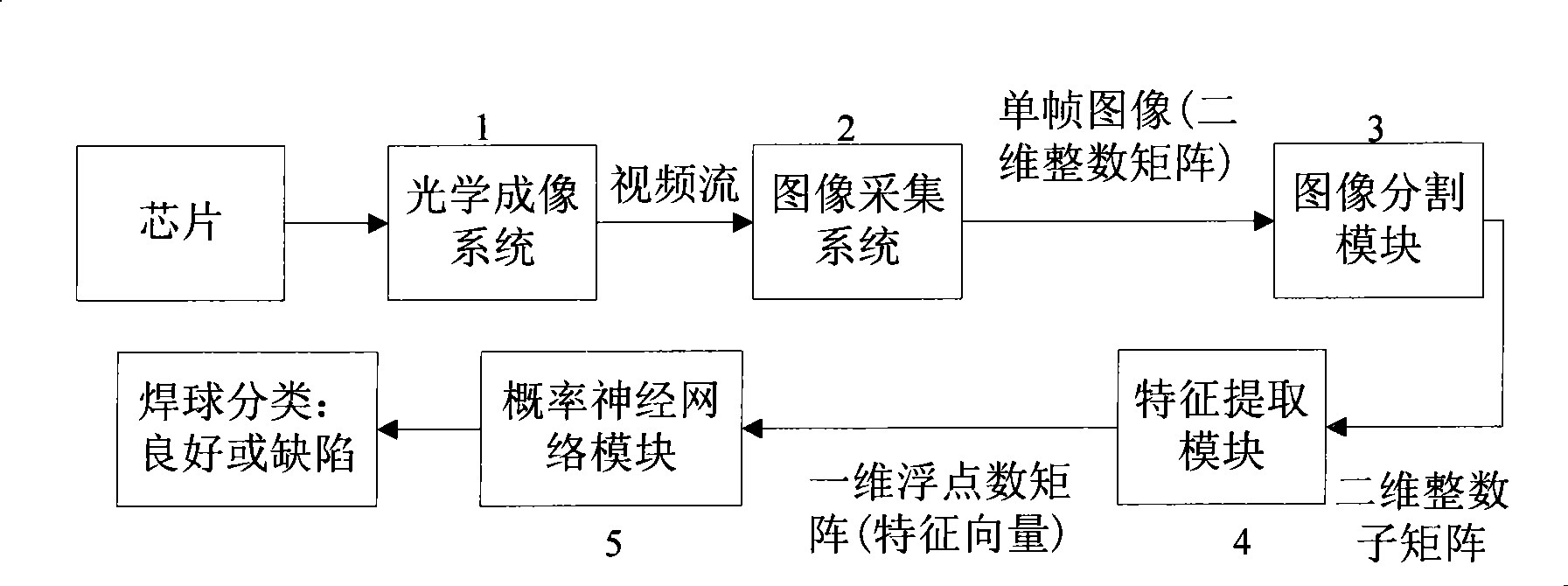

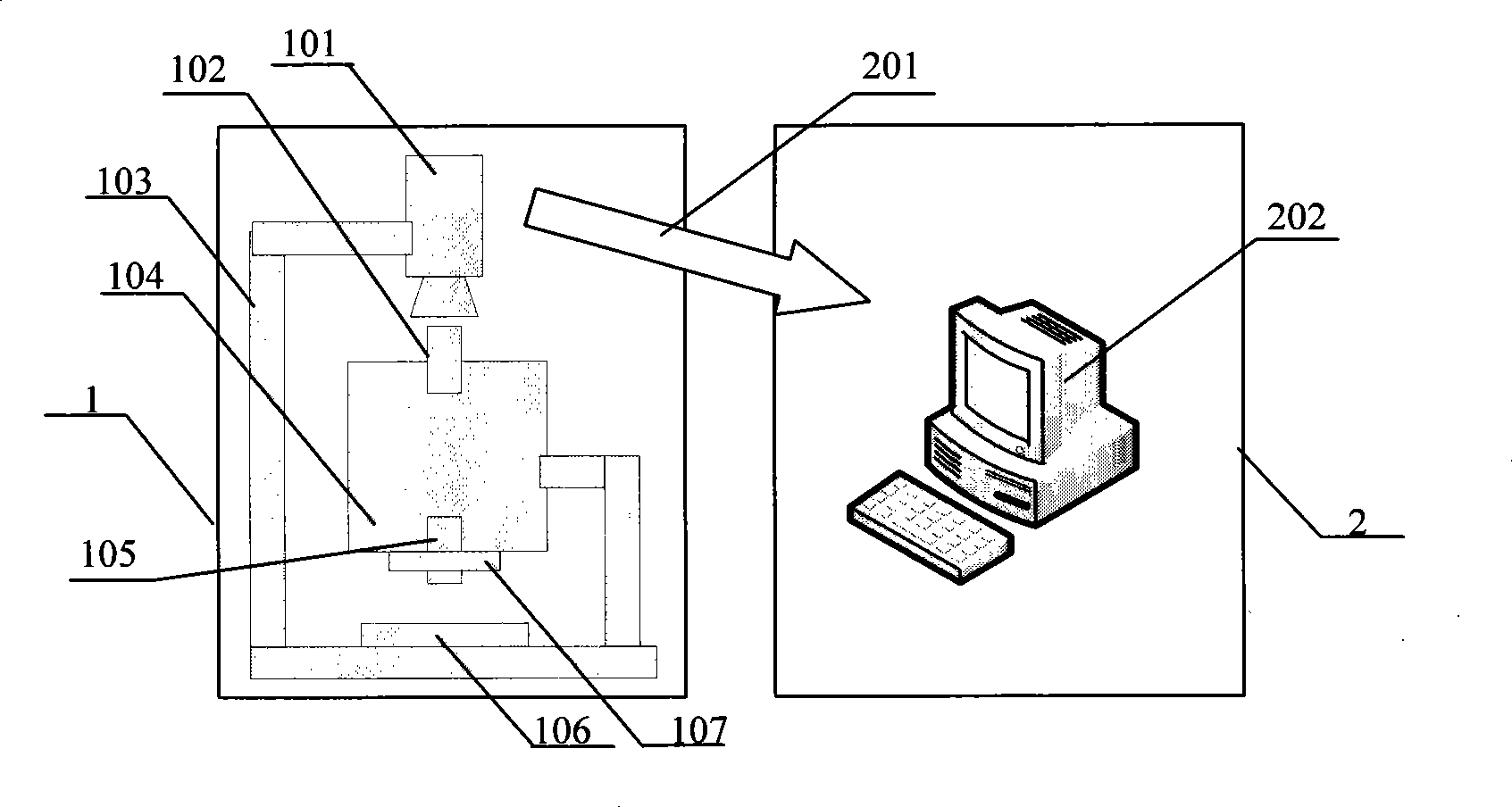

[0036] Such as figure 1 As shown, the device for detecting solder ball surface defects based on machine vision in this embodiment is composed of an optical imaging system 1, an image acquisition system 2, an image segmentation module 3, a feature extraction module 4, and a probabilistic neural network module 5. Among them:

[0037] The optical imaging system 1 uses a black and white CCD camera to collect chip images;

[0038] The image acquisition system 2 receives the chip image from the black and white CCD camera and transmits it to the computer, uses software to trigger the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com