Electrostatic charge image developer, process cartridge and image forming apparatus

一种静电图像显影、显影剂的技术,应用在显影剂、应用电荷图形的电记录工艺的设备、应用电荷图形的电记录工艺等方向,能够解决转印图像不均匀、球形调色剂颗粒溜走、转印难等问题,达到减少图像的不均匀和机内污染、减少不均匀和机内污染、减少再现性低下的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

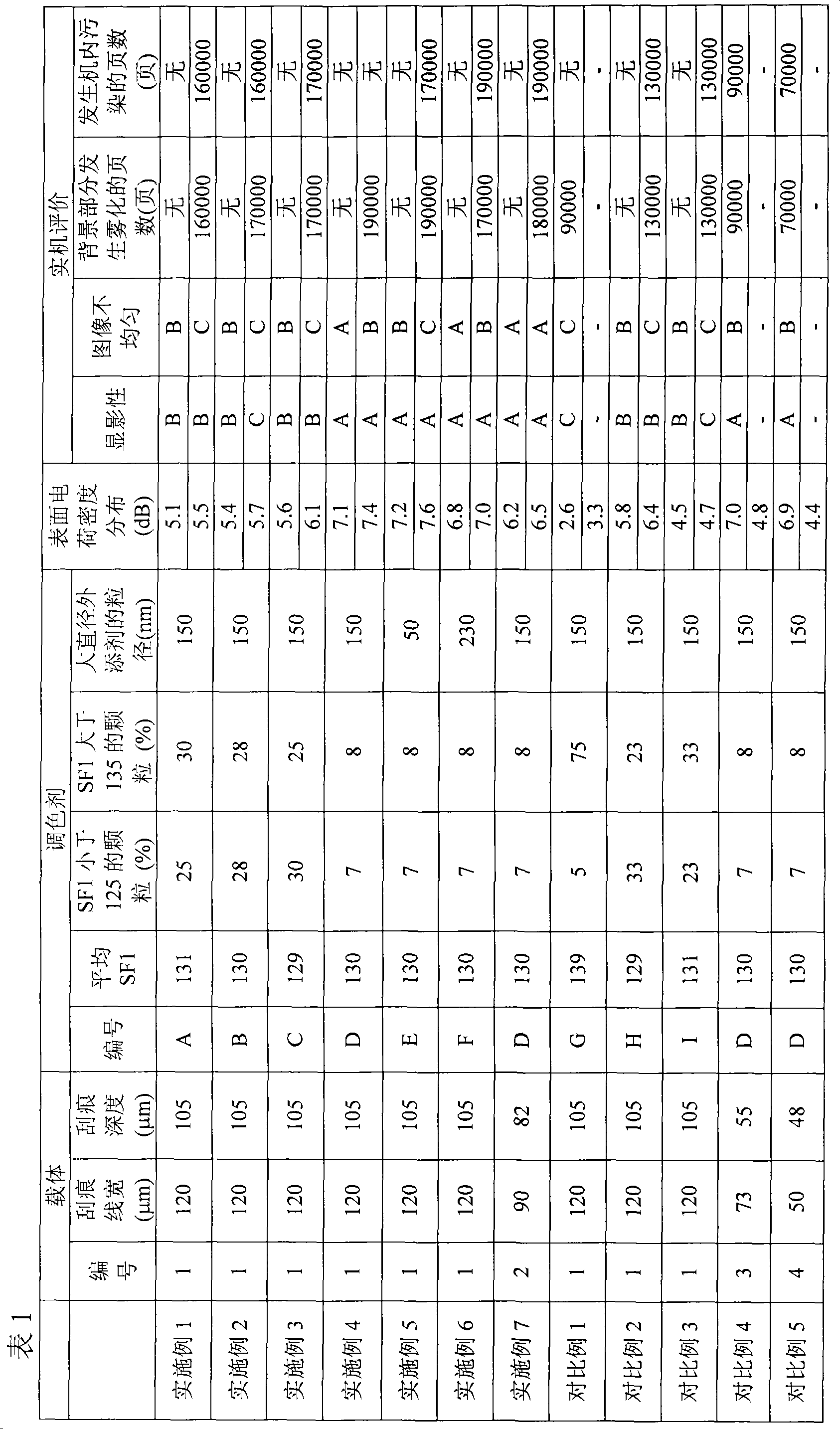

[0318] A developer (1) obtained by combining Carrier 1 and Toner A as shown in Table 1 was charged into a developing unit of DOCU CENTER COLOR A450 (trade name, manufactured by Fuji Xerox Co., Ltd.), and copying was performed test. First, a solid image of 2 cm×5 cm was copied in an environment of 22° C. and 50% RH, and the developer on the sleeve was sampled. The particle size and charge amount were measured by E-SPARTANALYZER, and the surface charge density distribution D represented by the formula (1) was calculated.

[0319] Next, by continuous printing, images to be described later are output on 100,000 sheets. During continuous printing, the number of pages with fogging in the background portion and the number of pages with in-machine contamination were obtained. Fogging and in-machine contamination of the background portion were evaluated based on the following criteria.

[0320] (fogging of the background part)

[0321] An image having two solid images of 2 cm x 5 c...

Embodiment 2~7

[0337] (embodiment 2~7, comparative example 1~5)

[0338] Each evaluation was performed in the same manner except that each developer obtained by combining each carrier and each toner shown in Table 1 was used instead of the developer (1) in Example 1, respectively. The results are summarized in Table 1.

[0339]

[0340] As shown in Table 1, in each embodiment, no matter in a normal temperature and humidity environment or a high temperature and high humidity environment, the fogging and internal contamination of the background part are stable, and will not cause obvious problems, and there is no problem with the image quality . On the other hand, in the comparative example, a problem occurred in at least one of the plurality of evaluation items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com