Novel ultra-thin type electromagnetic relay

An electromagnetic relay, ultra-thin technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve the problems of low breaking load capacity of contact parts, small mechanical reaction force of contact parts, low efficiency of relay magnetic circuit, etc., to achieve Increased creepage distance, improved dielectric withstand voltage, and improved magnetic circuit efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

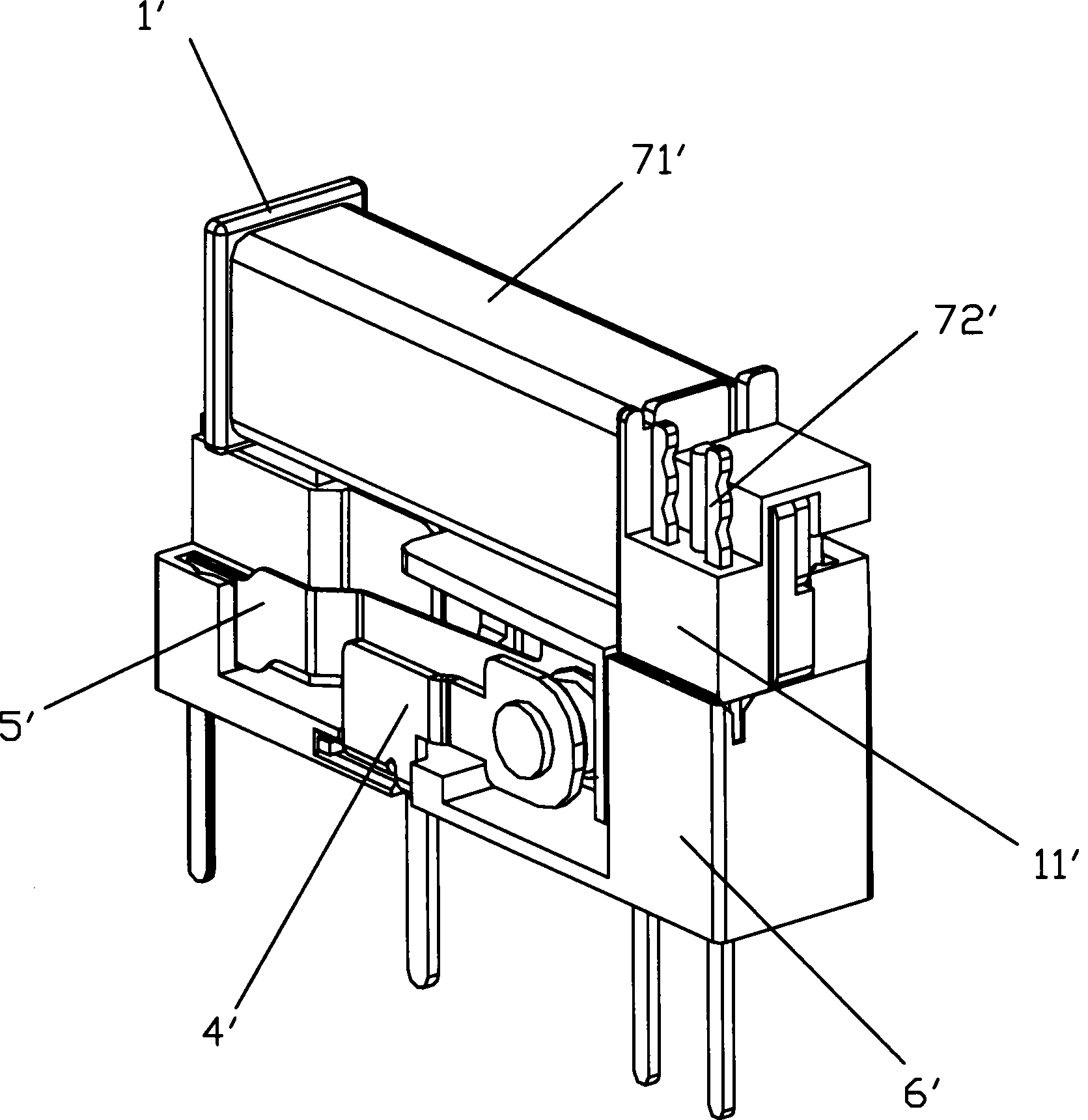

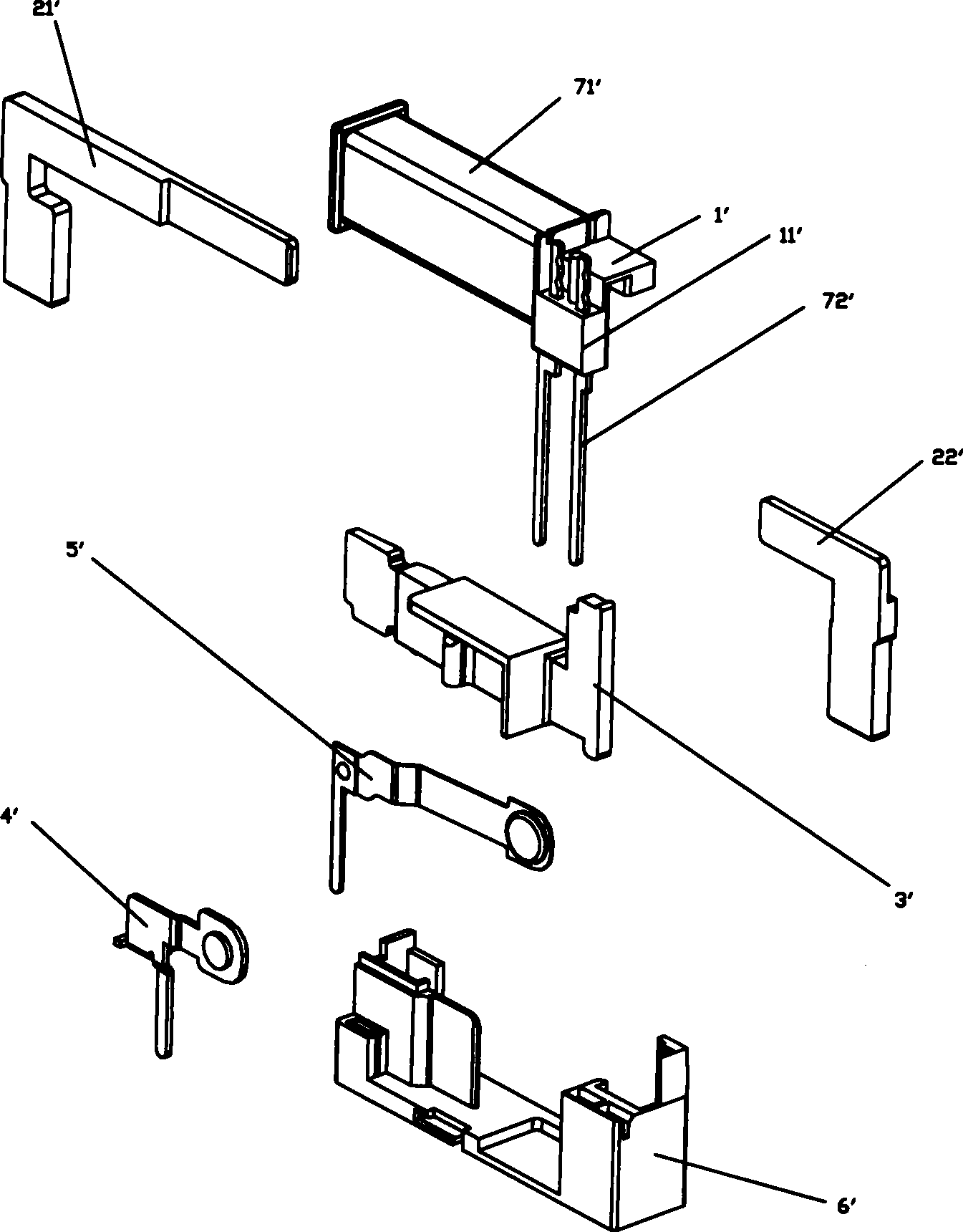

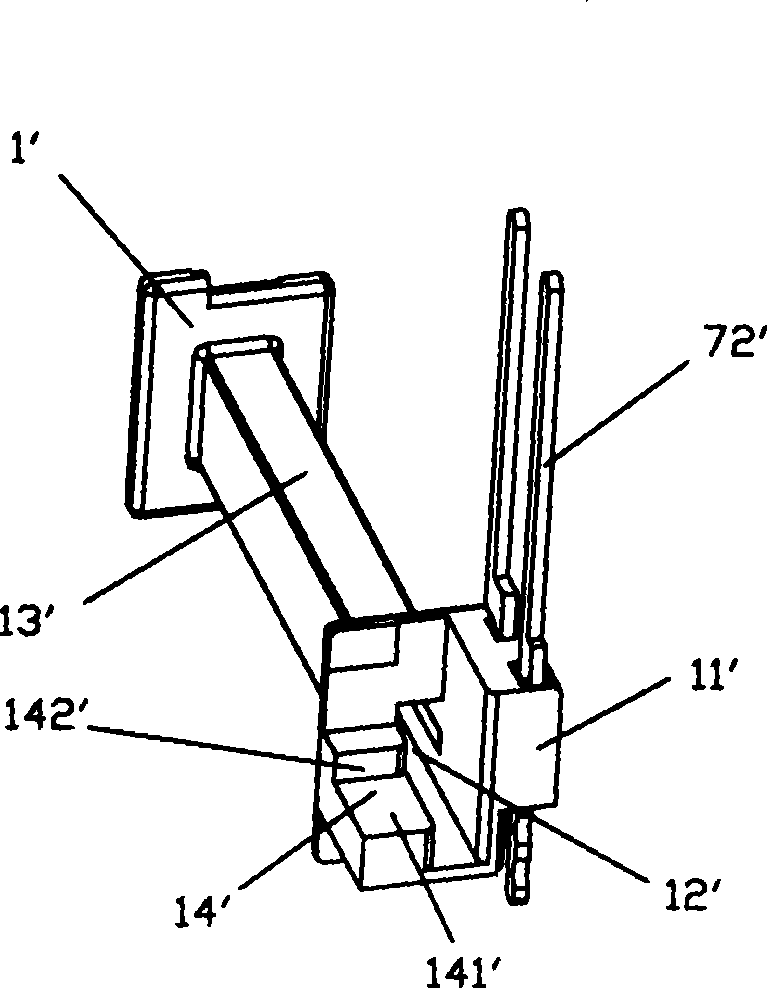

[0040] see Figure 8 to Figure 15 As shown, a new type of ultra-thin electromagnetic relay of the present invention includes a contact part, a magnetic circuit part, and a base; the contact part and the magnetic circuit part are correspondingly mounted on the base; the contact part includes a static reed assembly 4, Moving reed assembly 5; the magnetic circuit components include a coil frame 1, a yoke / iron core 2, an armature assembly 3, a base 6, a winding coil 71, and a coil pin 72; the coil pin 72 is fixed on the coil frame 1 In the part 11, the fixing part 11 is arranged on one side of the bobbin 1;

[0041] The yoke / core 2 of the magnetic circuit component is an integral structural member with an inverted U-shape;

[0042] The bottom end of the bobbin 1 of the magnetic circuit component is provided with a strip opening along the axis of its bobbin 13, and the strip opening of the bobbin extends to both sides so that the bottom end of the bobbin can be used Embedded yoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com