Hydrogen gas security protection system for fuel cell engine

A fuel cell and safety protection technology, applied in fuel cells, fuel cell additives, electrical components, etc., can solve problems such as high-pressure hydrogen gas leakage, fire, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

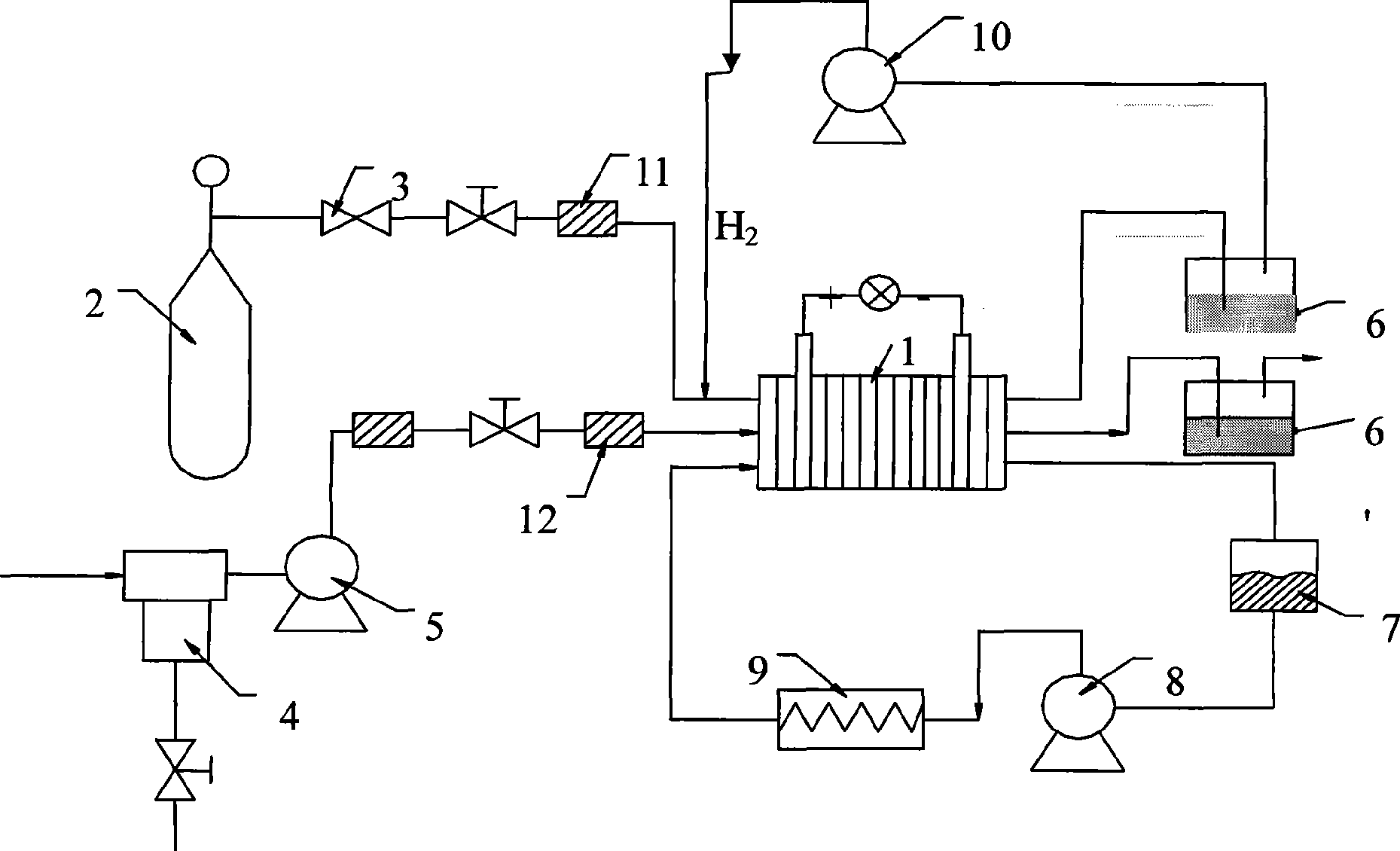

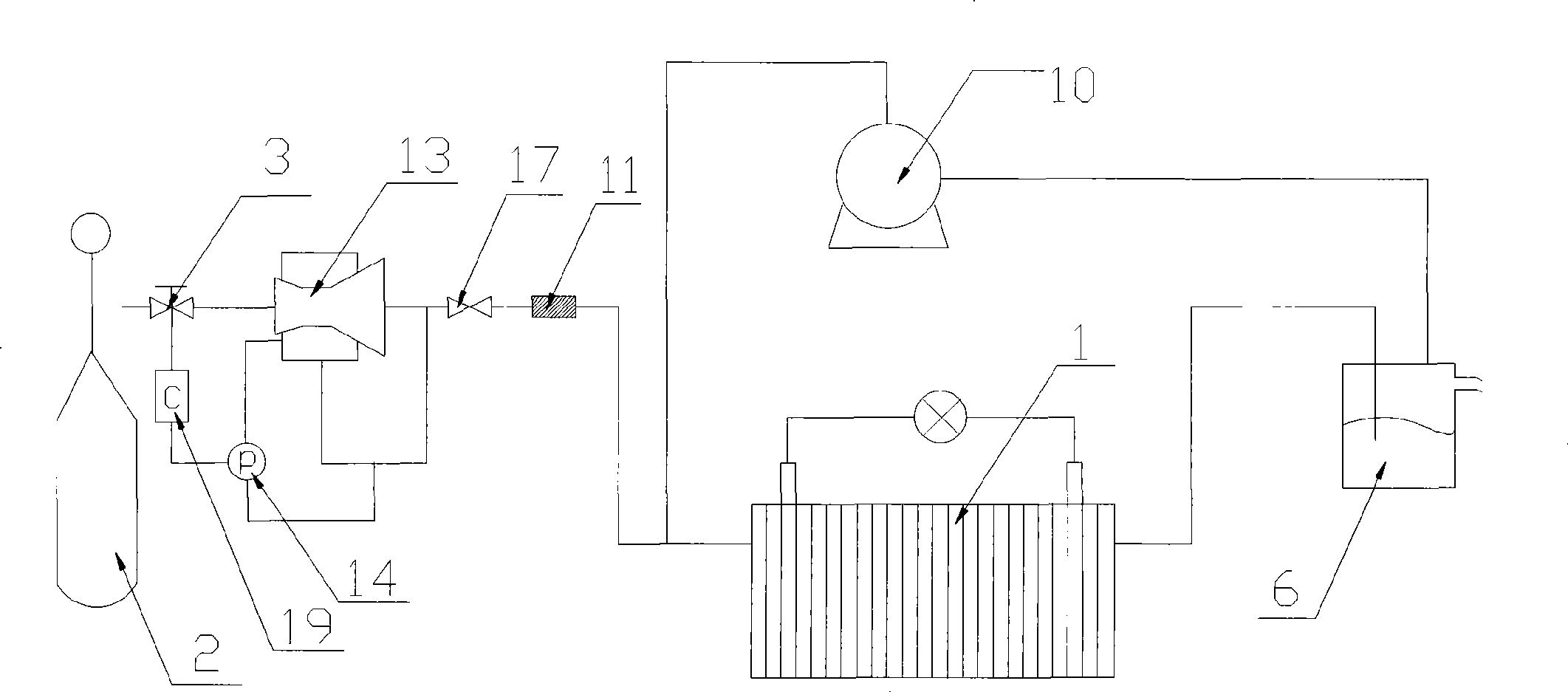

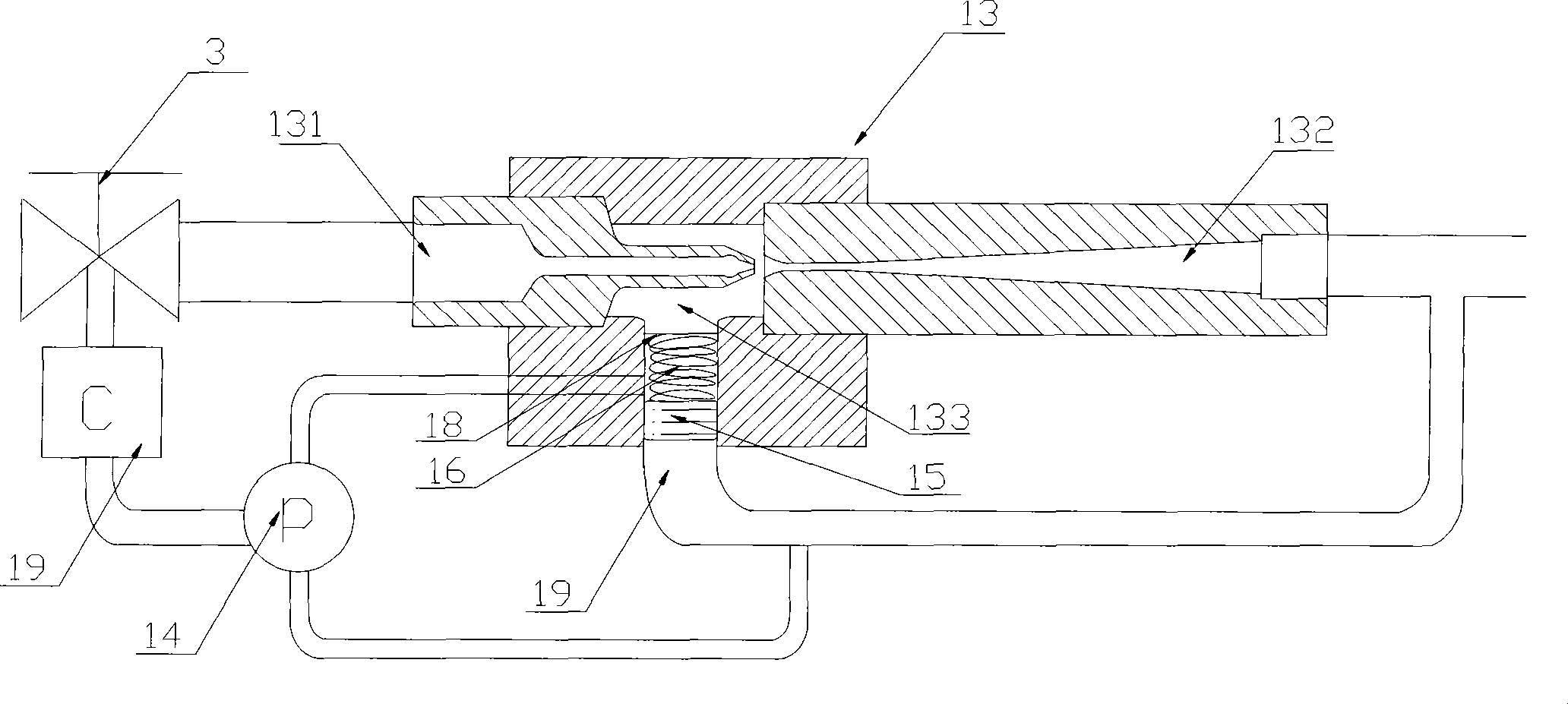

[0033] see Figure 1 ~ Figure 3 , a hydrogen circulation system of a 10kw fuel cell system, the allowable maximum flow rate of hydrogen is set to 100L / min, the sensors are respectively connected to the spring and the stop valve, when the hydrogen flows through the hydrogen decompression protection device, the sensor can detect The displacement variable or deformation rebound force △b generated by the spring deformation, the detection value a=k△b, the detection value a is transmitted to the controller, and the hydrogen is delivered or cut off by the controller controlling the cut-off valve switch. The cut-off valve is pneumatic After the hydrogen flows out of the hydrogen storage device, it passes through the stop valve and reaches the hydrogen decompression protection device to reduce the hydrogen pressure to 1 atm. After the hydrogen pressure is stabilized at 1 atm through the pressure stabilizing valve, it enters the fuel cell stack 1. When the hydrogen flow exceeds the allow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com