Internal bridge connecting and protection implementing method for linkage standby electricity supply mode

A technology of internal bridge wiring and backup power supply, applied in emergency protection circuit devices, electrical components, circuit devices, etc., can solve the problems of increased cost, system complexity, and increased system complexity, and achieves the goal of reducing system cost and simplifying system design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the description.

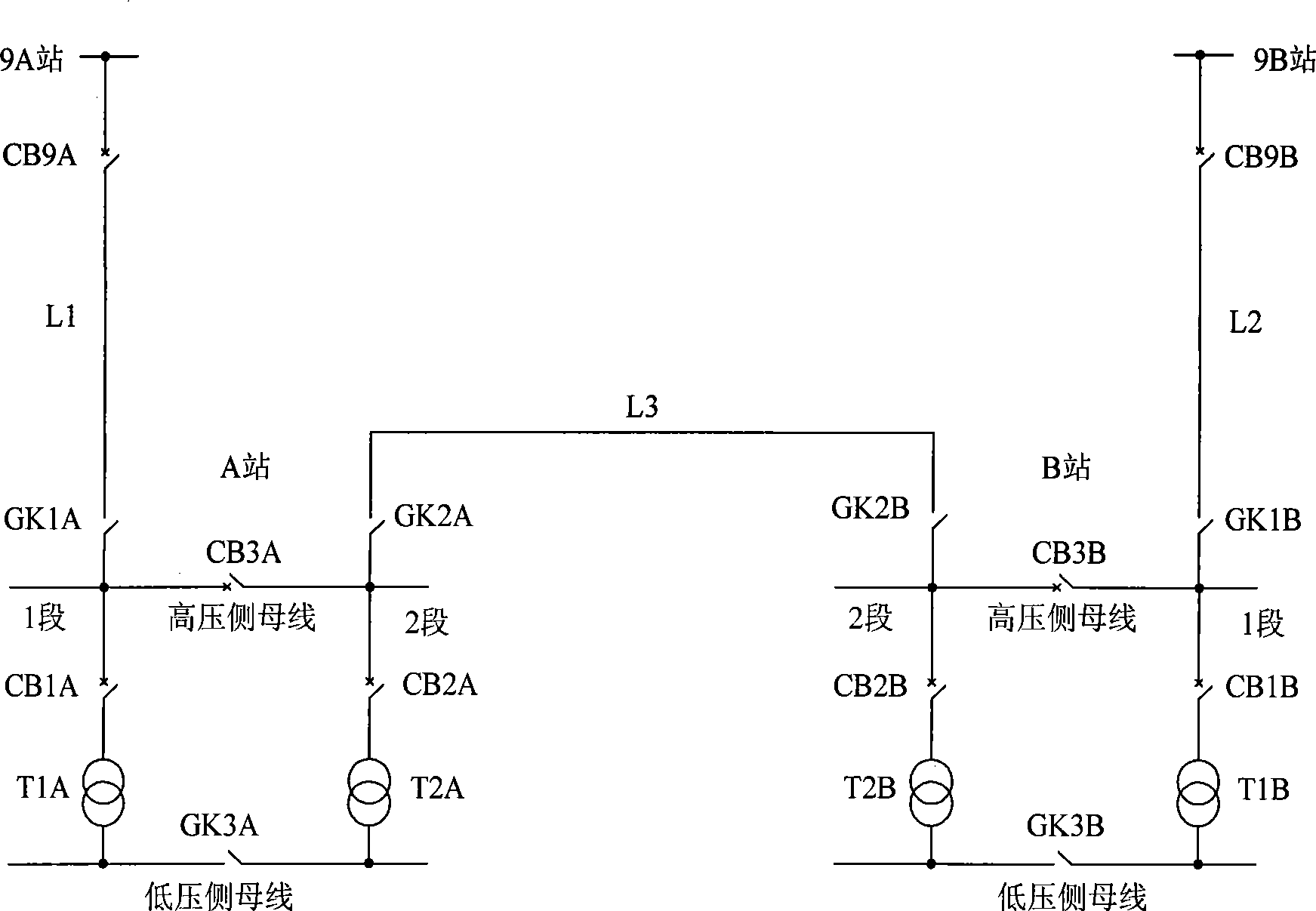

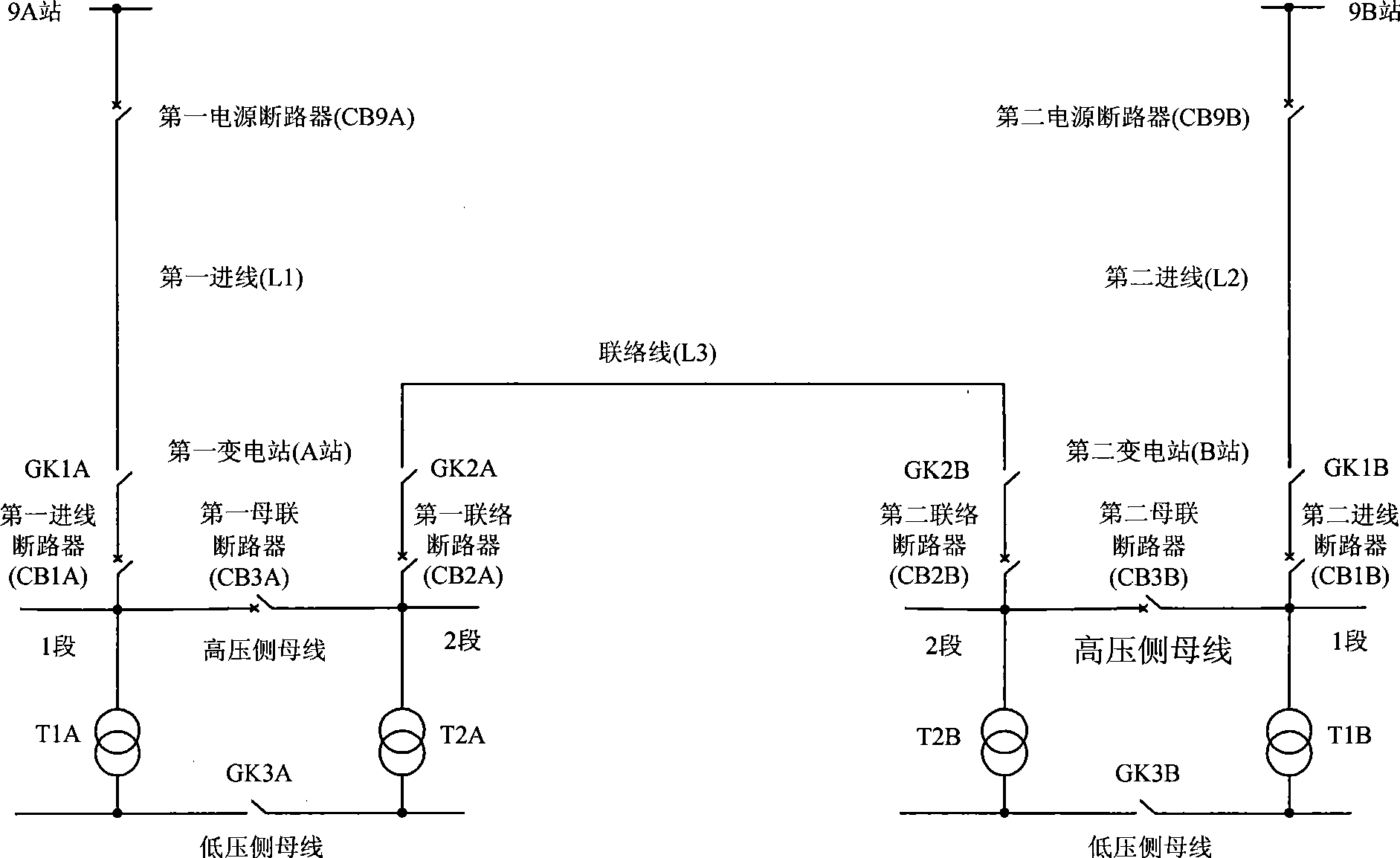

[0027] Such as figure 2 Shown is the wiring diagram of the inner bridge wiring mode of the present invention, the first substation A and the second substation B are two adjacent substations, and the power supply is provided by the first incoming line L1 and the second incoming line L2 respectively, in order to ensure reliable power supply Specifically, the high-voltage side bus bar of the first substation A is connected to the high-voltage side bus bar of the second substation B through a tie line to form a backup power supply mode for linking two substations, which is characterized by:

[0028] Install a first tie circuit breaker CB2A between the tie line and the 2-section bus on the high-voltage side of the first substation A, and install a second tie circuit breaker CB2B between the tie line and the 2-section b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com