Nozzle apparatus and semiconductor processing apparatus employing the nozzle apparatus

A nozzle device and semiconductor technology, applied in the field of microelectronics, can solve problems such as large dependence on external components, and achieve the effects of small dependence, easy installation and disassembly, and easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

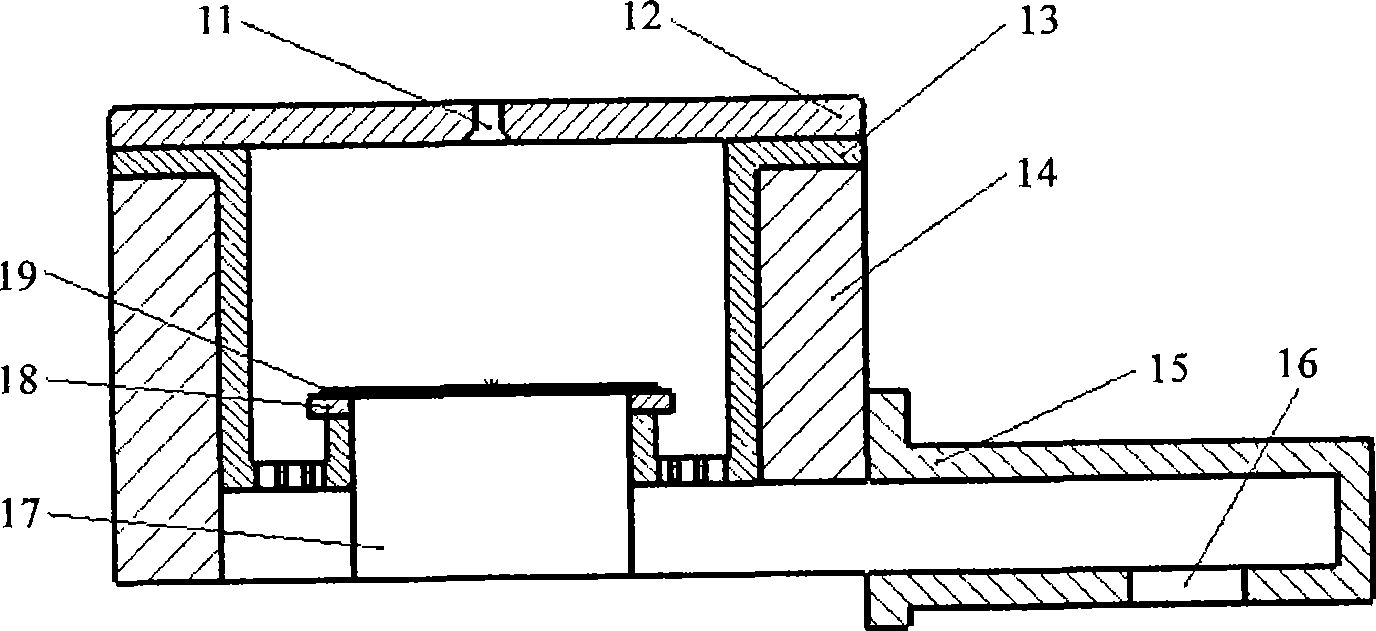

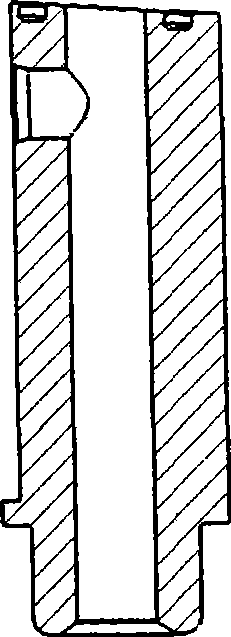

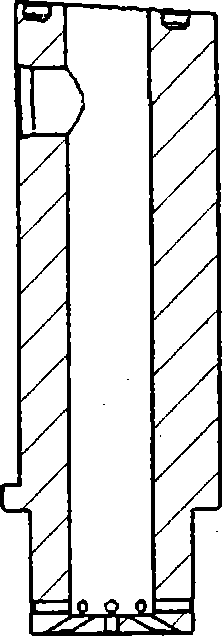

[0047] The technical core of the nozzle device provided by the present invention and the semiconductor processing equipment using the nozzle device is that by connecting the inlet part and the outlet part of the nozzle device into one body, and making the outlet part include a cavity connected to the inlet part, Therefore, the nozzle device is not only easy to assemble and disassemble and seal, but also has less dependence on external components; at the same time, it also makes the semiconductor processing equipment using the nozzle device easy to disassemble and seal. In addition, the nozzle device provided by the present invention and the semiconductor processing equipment using the nozzle device can make the gas entering the reaction chamber uniformly reach the surface of the processed / processed device such as a wafer, so that the processing / treatment of the processed / processed device surface The rate is uniform, which in turn leads to good machining / handling results.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com