Method for extracting biological sclerotin calcium phosphate

An extraction method and calcium phosphate technology are applied in the field of extracting bone calcium phosphate from bovine bones, which can solve the problems of low absorption and utilization rate and low calcium content, and achieve the effect of increasing bone density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

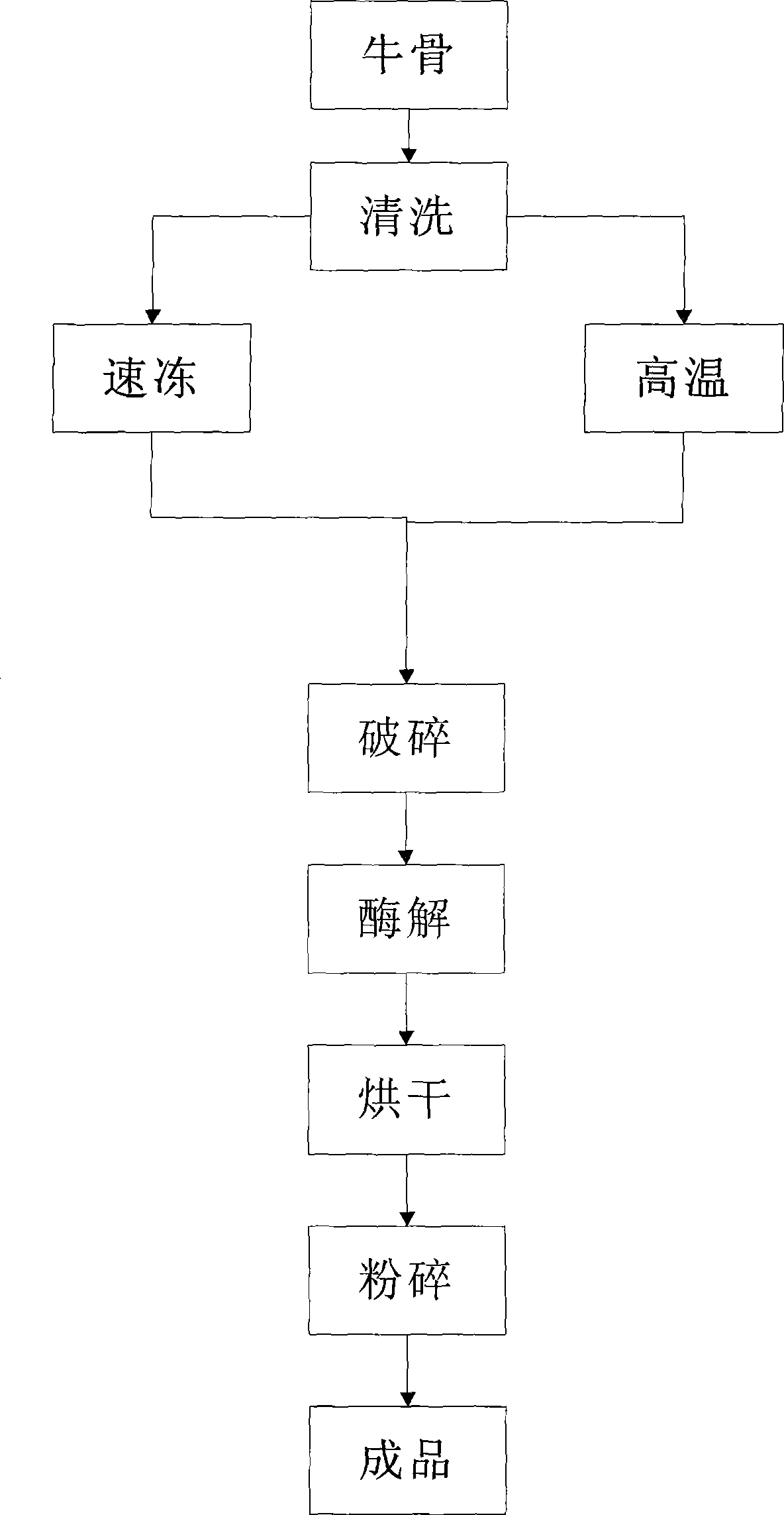

Image

Examples

Embodiment 1

[0019] a) Cleaning process: use pure water to wash fresh beef bones to remove blood stains and sundries;

[0020] b) Quick-freezing process: freezing the cleaned bovine bones to -40°C, which not only prevents the pollution and deterioration of fresh bovine bones, but also improves the fragility of bovine bones to facilitate the crushing and grinding of bovine bones;

[0021] c) High-temperature process: wash the cleaned bovine bone and then process it in a high-temperature furnace at 1100°C for 30 minutes to remove grease, bone marrow and other useless substances in the bovine bone and improve the ratio of phosphorus to calcium;

[0022] d) Crushing process: After mixing the bovine bones prepared by the quick-freezing process and the bovine bones prepared by the high-temperature process, they are crushed into 80-100 meshes. The weight ratio of the bovine bones prepared by the quick-freezing process to the bovine bones prepared by the high-temperature process is 1:1.5.

[0023]...

Embodiment 2

[0028] a) Cleaning process: use pure water to wash fresh beef bones to remove blood stains and sundries;

[0029] b) Quick-freezing process: freezing the cleaned bovine bones to -60°C, which not only prevents the pollution and deterioration of fresh bovine bones, but also improves the fragility of bovine bones to facilitate the crushing and grinding of bovine bones;

[0030] c) High temperature process: process the cleaned bovine bone in a high temperature furnace at 1150°C for 40 minutes to remove fat, bone marrow and other useless substances in the bovine bone and improve the ratio of phosphorus to calcium;

[0031] d) Crushing process: After mixing the bovine bones prepared by the quick-freezing process and the bovine bones prepared by the high-temperature process, they are crushed into 80-100 meshes. The weight ratio of the bovine bones prepared by the quick-freezing process to the bovine bones prepared by the high-temperature process is 1:2.

[0032] e) Enzymolysis proces...

Embodiment 3

[0037] a) Cleaning process: use pure water to wash fresh beef bones to remove blood stains and sundries;

[0038] b) Quick-freezing process: freezing the cleaned bovine bones to -80°C, which not only prevents the pollution and deterioration of fresh bovine bones, but also improves the fragility of bovine bones to facilitate the crushing and grinding of bovine bones;

[0039] c) High-temperature process: process the cleaned beef bone in a high-temperature furnace at 1200°C for 50 minutes to remove grease, bone marrow and other useless substances in the beef bone and improve the phosphorus-calcium ratio;

[0040] d) Crushing process: After mixing the bovine bones prepared by the quick-freezing process and the bovine bones prepared by the high-temperature process, they are crushed into 80-100 meshes. The weight ratio of the bovine bones prepared by the quick-freezing process to the bovine bones prepared by the high-temperature process is 1:2.5.

[0041] e) Enzymolysis process: un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com