Magnetic steel collar

A ring and magnetic technology, applied in textiles and papermaking, can solve the problems of rapid wear, restricting the output and quality of ring spinning, friction and heat generation, etc., and achieve the effects of reducing wear, improving quality and reducing spinning ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

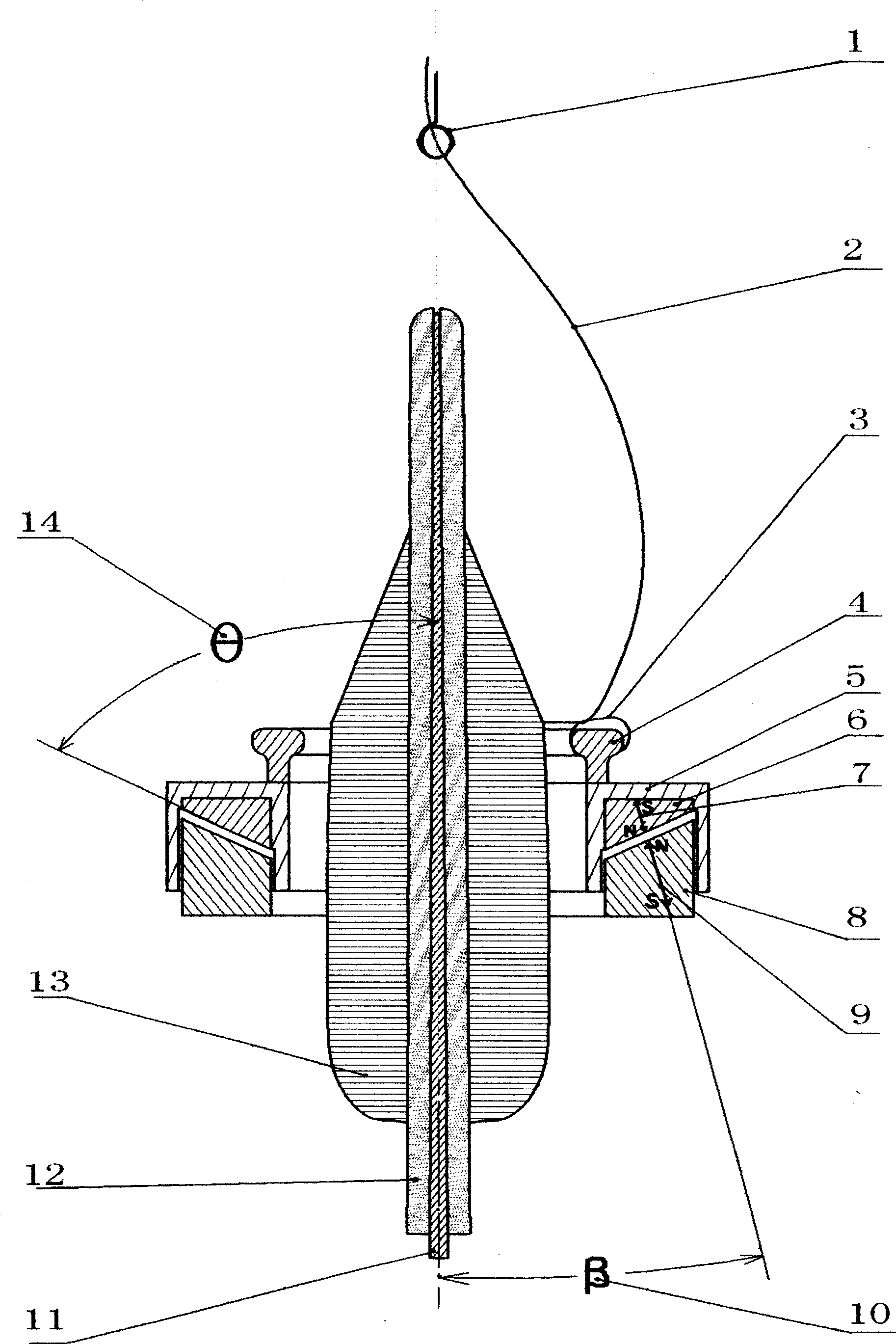

[0010] In the figure, the magnetic levitation layer (6) is installed above the magnetic base (8) and coaxial with the magnetic base (8). Because the magnetic pole direction (7) of the magnetic levitation layer is opposite to the magnetic pole direction (9) of the magnetic base, from the axial section of the spindle (11) axis, the opposite surface of the magnetic levitation layer (6) and the magnetic base (8) is opposite to the spindle There is an included angle (14) between the axes. Therefore, the magnetic suspension layer (6) is suspended above the magnetic base (8), the magnetic isolation layer (5) is fixedly installed on the magnetic suspension layer (6), the circular track (4) is fixedly installed on the magnetic isolation layer (5), and the steel wire Circle (3) is looped on the annular track (4). When working, the yarn (2) is output from the front jaw, passes through the traveler (3) after passing through the yarn guide hook (1), and then is wound on the bobbin (12) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com