Major cycle slanting extraction method for coal mining work surface

A technology for coal mining face and working face, applied in ground mining, mining equipment, earthwork drilling and other directions, can solve the problems of slow speed, low efficiency, cluttered process, etc. The effect of mining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

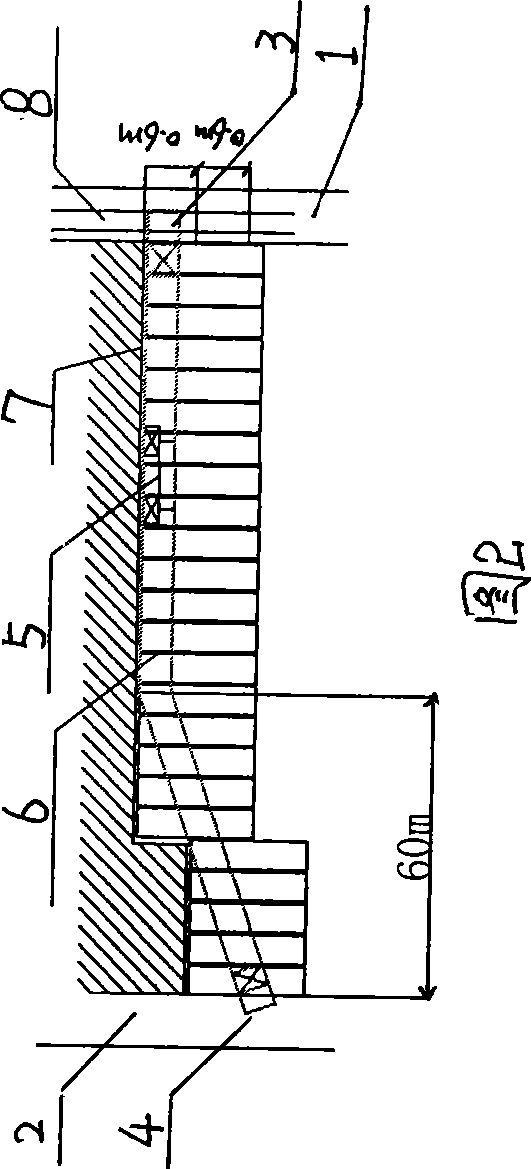

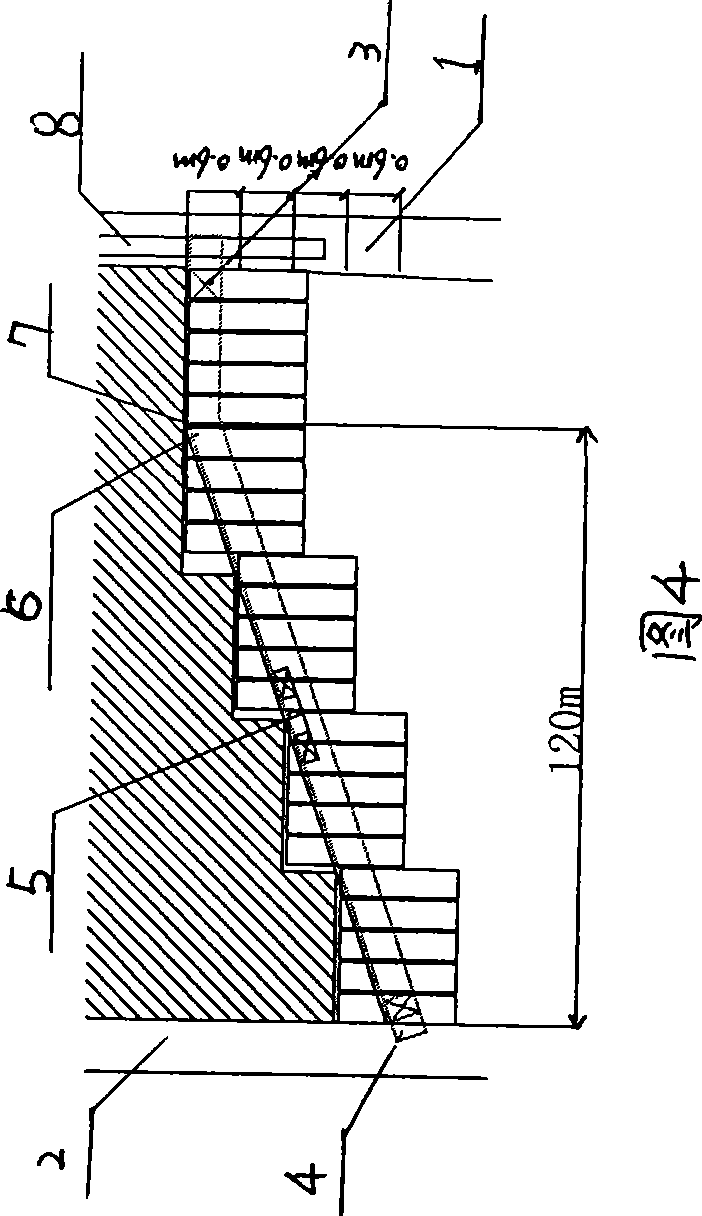

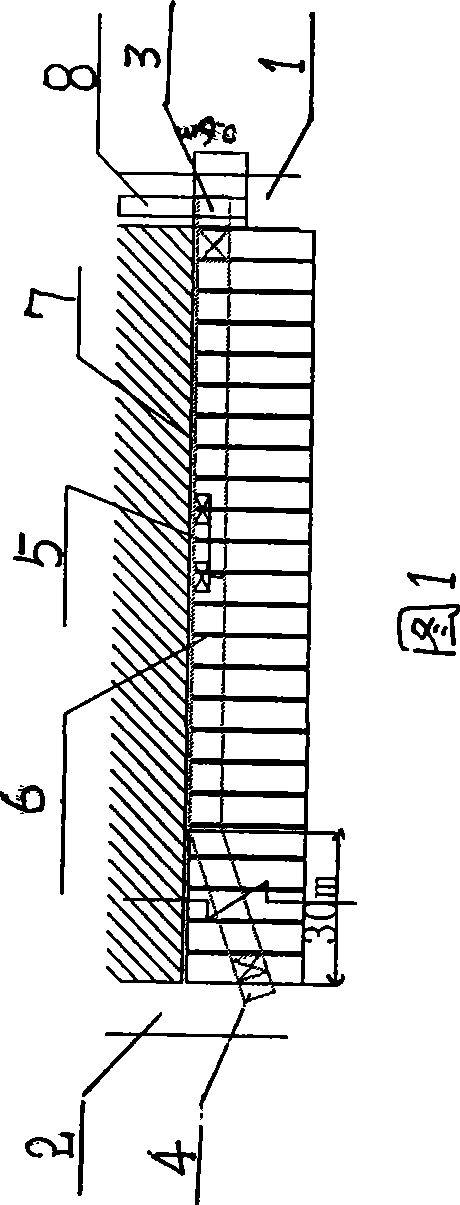

[0021] Below is to be 150m with working face length, is divided into five sections by 30m one section from nose to tail as an example to set forth the oblique mining method of the present invention, the maximum cutting depth of shearer is 0.6m.

[0022] (1) As shown in Figure 1, when the inclined mining starts, the coal shearer 5 cuts the knife normally at the head, and cuts coal normally in the direction of the tail. In the first stage, carry out the inclined top slide 6, and the slide distance gradually decreases from 0.6m to zero from the nose to the tail. Small inclined mining cycle; (2) As shown in Figure 2, after the shearer enters the knife in the second section, the shearer will normally cut coal from the second section to the fifth section in the direction of the machine head, and the shearer will cut coal in the second section When moving the chute inward, the step distance of the chute gradually increases from zero to 0.6m from the tail to the nose, the chute moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com