Catalyst for removing trace amounts of olefin hydrocarbon in arene

A catalyst, a technology for removing olefins, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of ineffective removal, short operation period, unfavorable environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

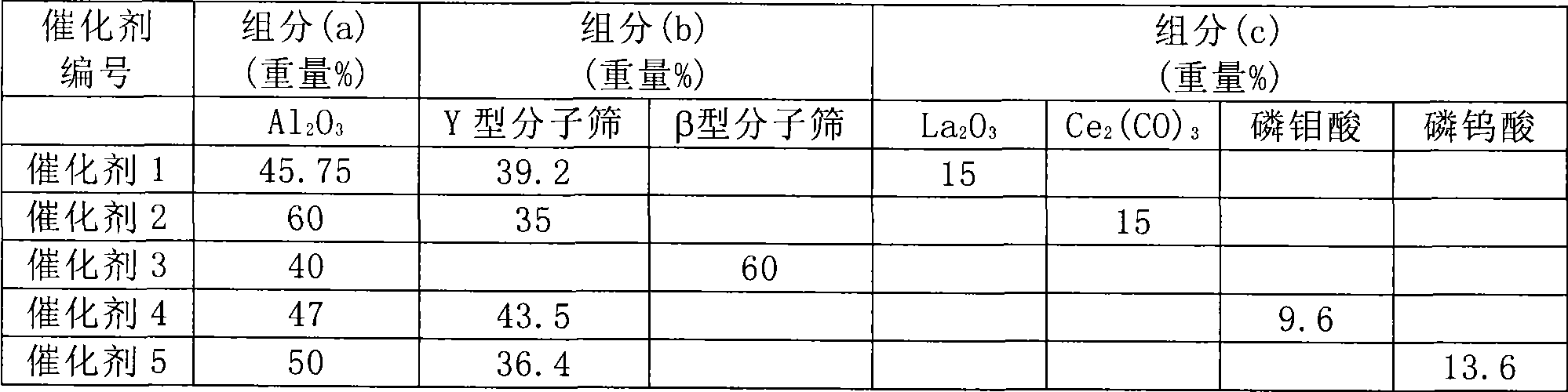

[0034] The preparation method of deolefin catalyst of the present invention comprises the following steps:

[0035] (1) Mix alumina and molecular sieve powder evenly;

[0036] (2) Add lanthanide rare earth, P, W, Nb, M to the uniformly mixed powder in step (1) o The compound of at least one metal, then add acid, mix, or the compound of at least one element selected from lanthanide rare earth, P, W, Nb, Mo is dissolved in acid, and the solution is added to step (1) In the prepared mixture, mix;

[0037] (3) extruding the mixture obtained in step (2) into strips;

[0038] (4) Roasting the strips prepared in step (3) at 350-750° C. for 3-9 hours.

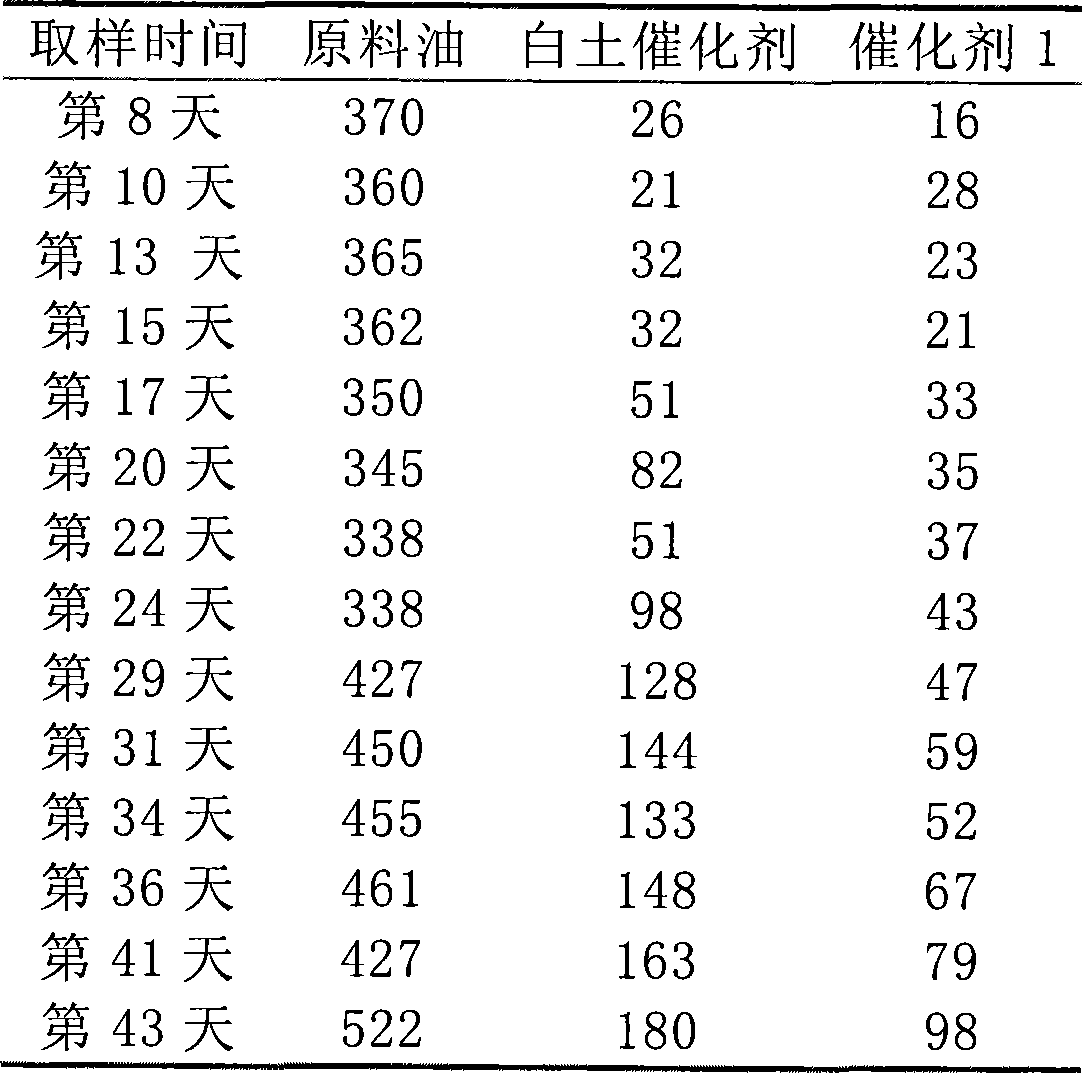

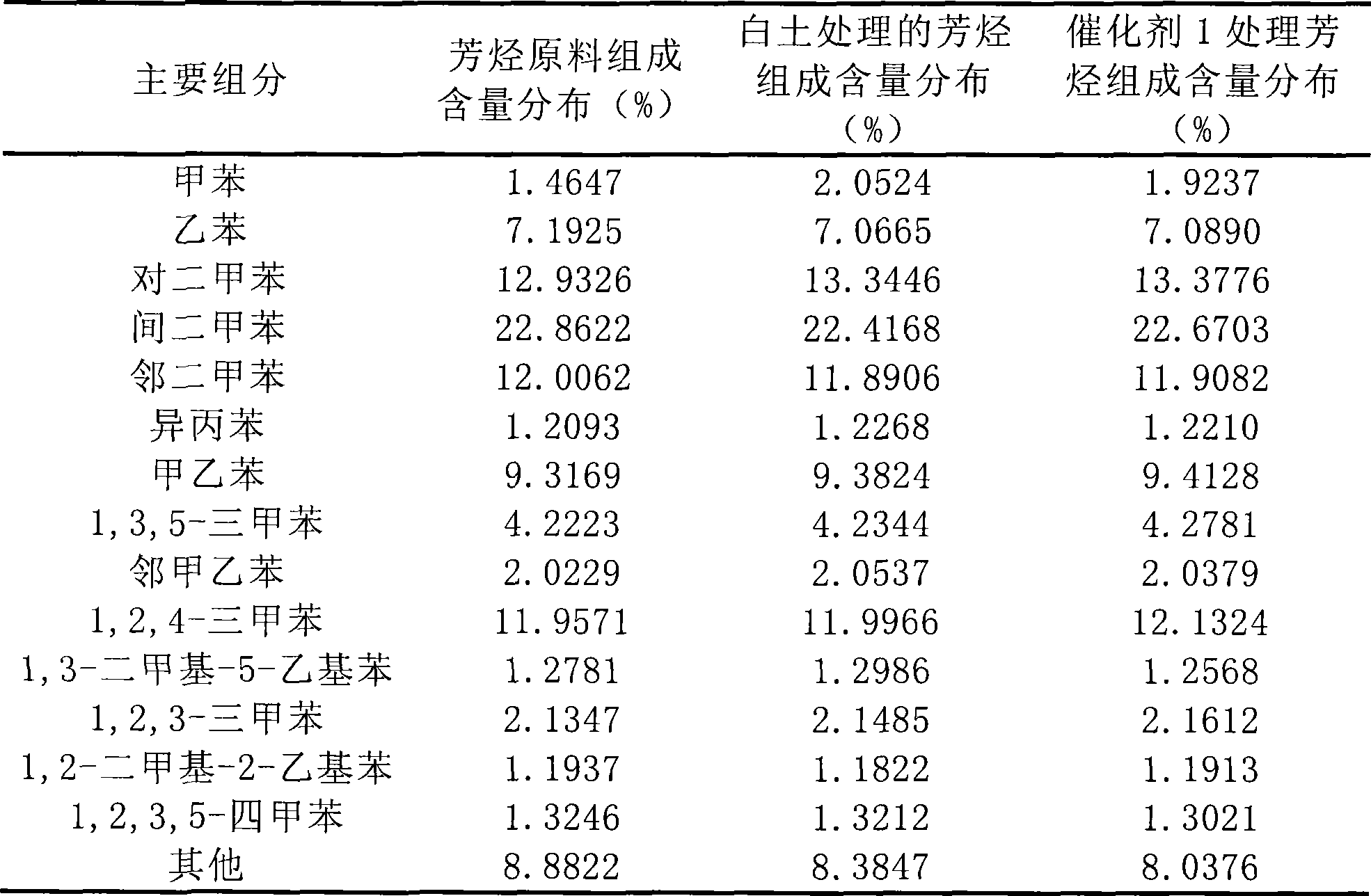

[0039] As a catalyst for removing trace olefins in aromatics, the present invention can be directly filled into the clay tower without rebuilding the device, which saves construction costs. In addition, the clay needs to be replaced in a short period of time. Compared with the clay catalyst, the catalyst of the present invention has...

preparation example 1

[0046] 60 g NH 4 Add 70 grams of Al to Y molecular sieve 2 o 3 , 23 grams La 2 o 3 ,well mixed;

[0047] Add 40ml of nitric acid dropwise to the mixture, mix well and extrude;

[0048] The above catalyst was calcined at 450°C for 9 hours, and the obtained solid catalyst was Catalyst 1.

preparation example 2

[0050] 70 g NH 4 Add 100 grams of Al to Y molecular sieve 2 o 3 , 30 g Ce 2(CO 3 ) 3 ,well mixed;

[0051] Add 50ml of nitric acid dropwise to the mixture, mix well and extrude;

[0052] The above catalyst was calcined at 400°C for 9 hours, and the obtained solid catalyst was Catalyst 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com