Grinding device

A grinding and mounting technology, which is applied in the direction of grinding drive device, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of camera cost, wafer crack, and insufficient center position alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

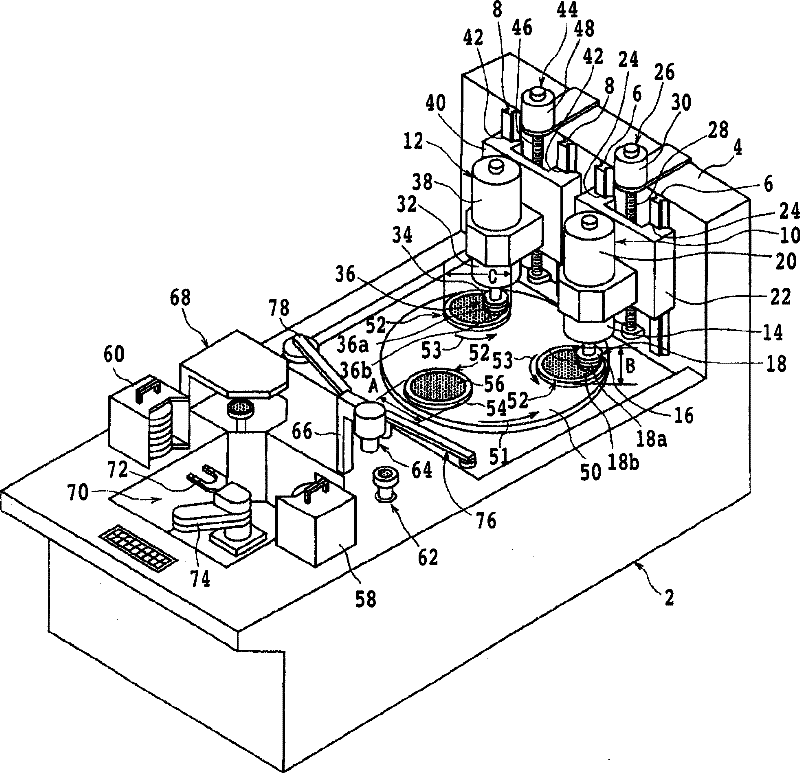

[0041] A grinding device according to an embodiment of the present invention will be described in detail below with reference to the drawings. refer to figure 1 , figure 1 A perspective view showing a grinding device according to an embodiment of the present invention. The grinding device includes a substantially cuboid-shaped device housing 2 . The vertical support plate 4 is adjacent to the upper right end of the device housing 2 .

[0042] Two pairs of guide rails 6 and 8 extending in the vertical direction are provided on the inner side of the vertical support plate 4 . A rough grinding unit 10 is vertically movable to one guide rail 6 , and a finish grinding unit 12 is vertically movable to the other guide rail 8 .

[0043]The rough grinding unit 10 is constituted to have: a unit housing 14; a grinding wheel 18 mounted on a wheel base 16 which is freely rotatable and mounted on the lower end of the unit housing 14; an electric motor 20 mounted on the The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com