typesetting machine

A typesetting machine and rack technology, applied in sustainable manufacturing/processing, instrument, final product manufacturing, etc., can solve the problems of cell or substrate glass wear, inconvenient detection and positioning, etc., to improve position accuracy and improve matching accuracy. , the effect of precise offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

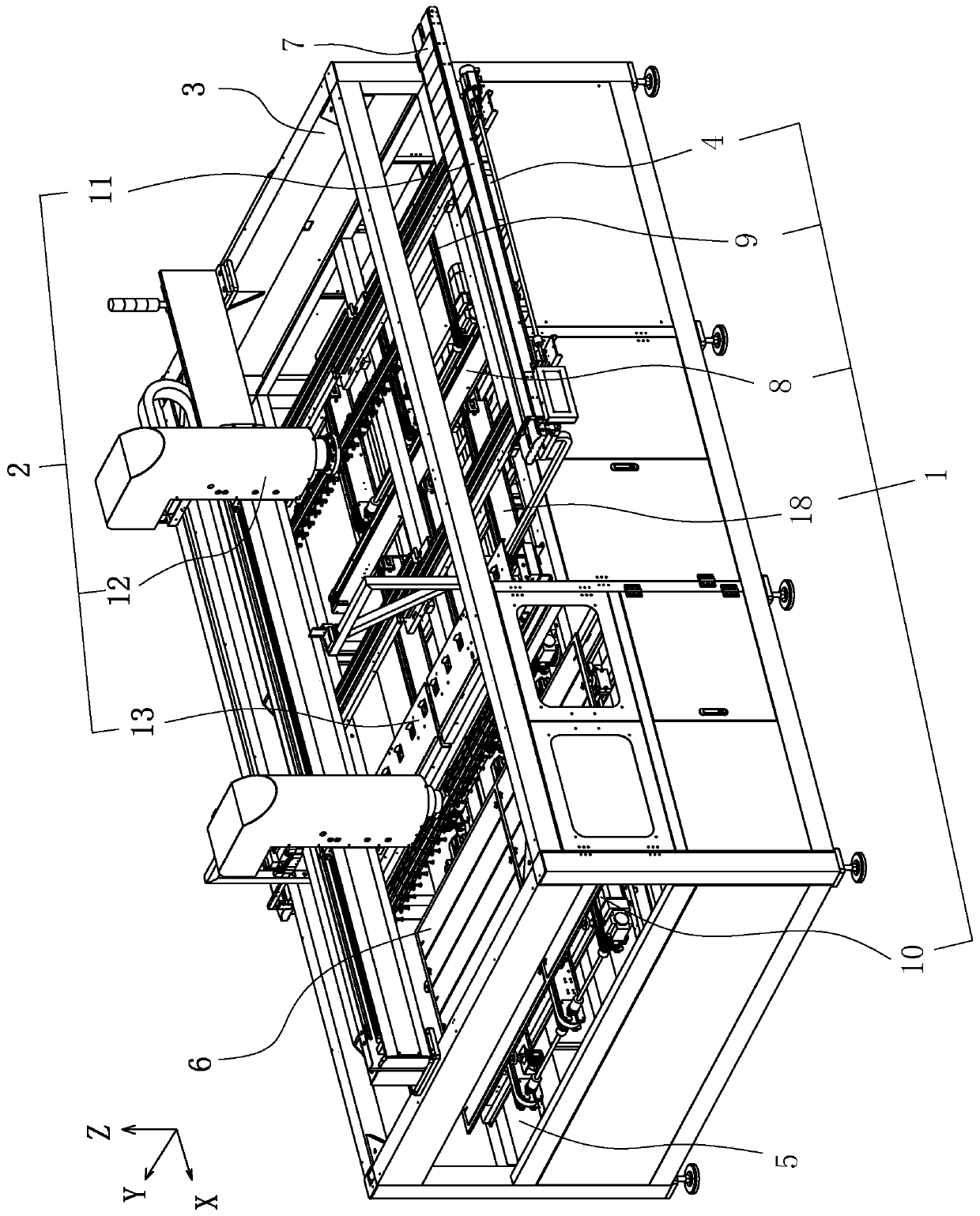

[0049] refer to figure 1 , a typesetting machine, including frame 3, glass delivery system 1 and battery string delivery system 2; The string conveying system 2 includes a battery string transport mechanism 11 , a battery string grasping mechanism 12 and a battery string normalizing mechanism 13 .

[0050] The composition and structure of various mechanisms and components will be described below according to the order in which the battery strings 7 are laid out on the substrate glass 6 .

[0051] The frame 3, substrate glass 6 and battery string 7 mentioned below all refer to figure 1 .

[0052] About the glass transmission mechanism 8:

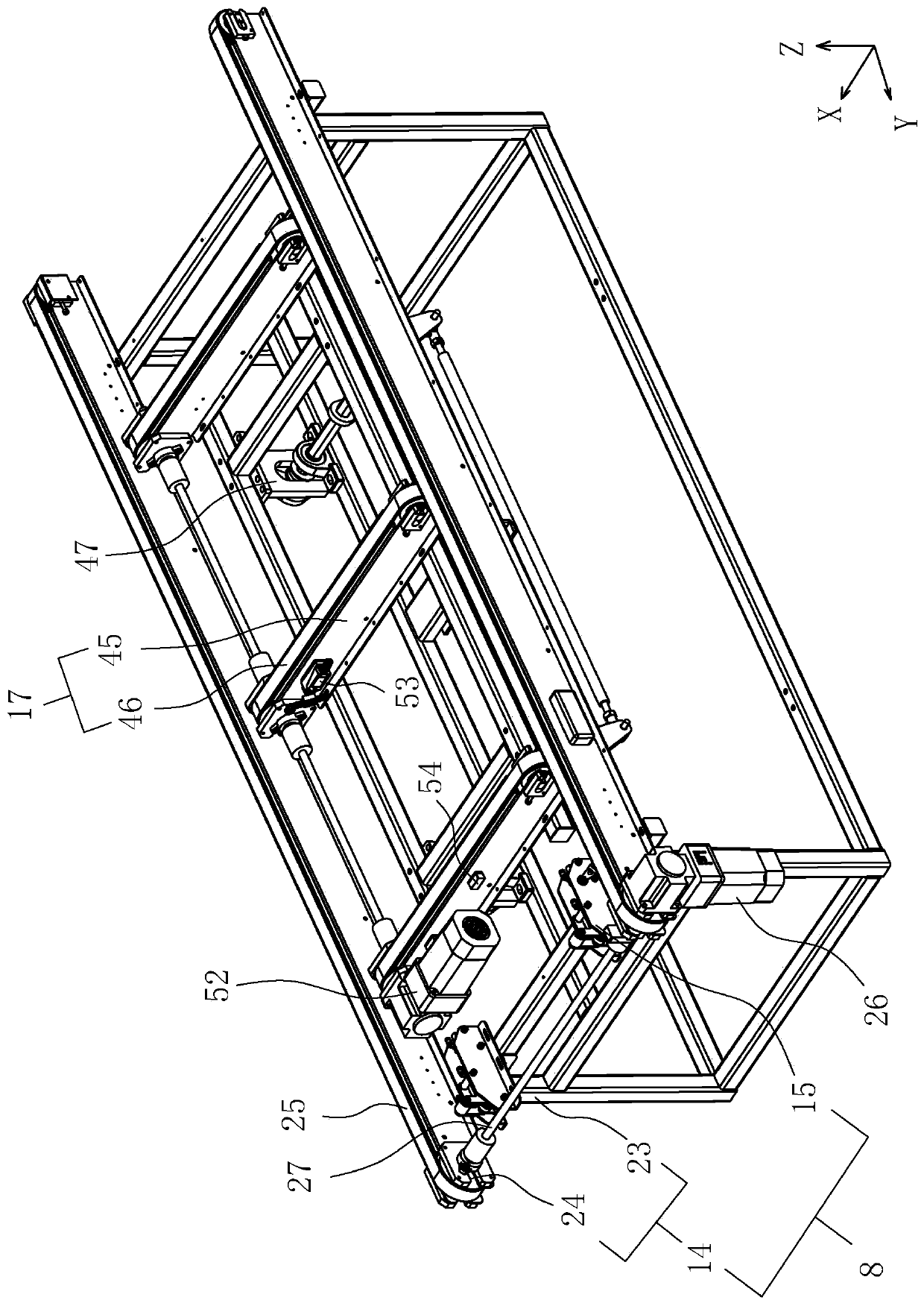

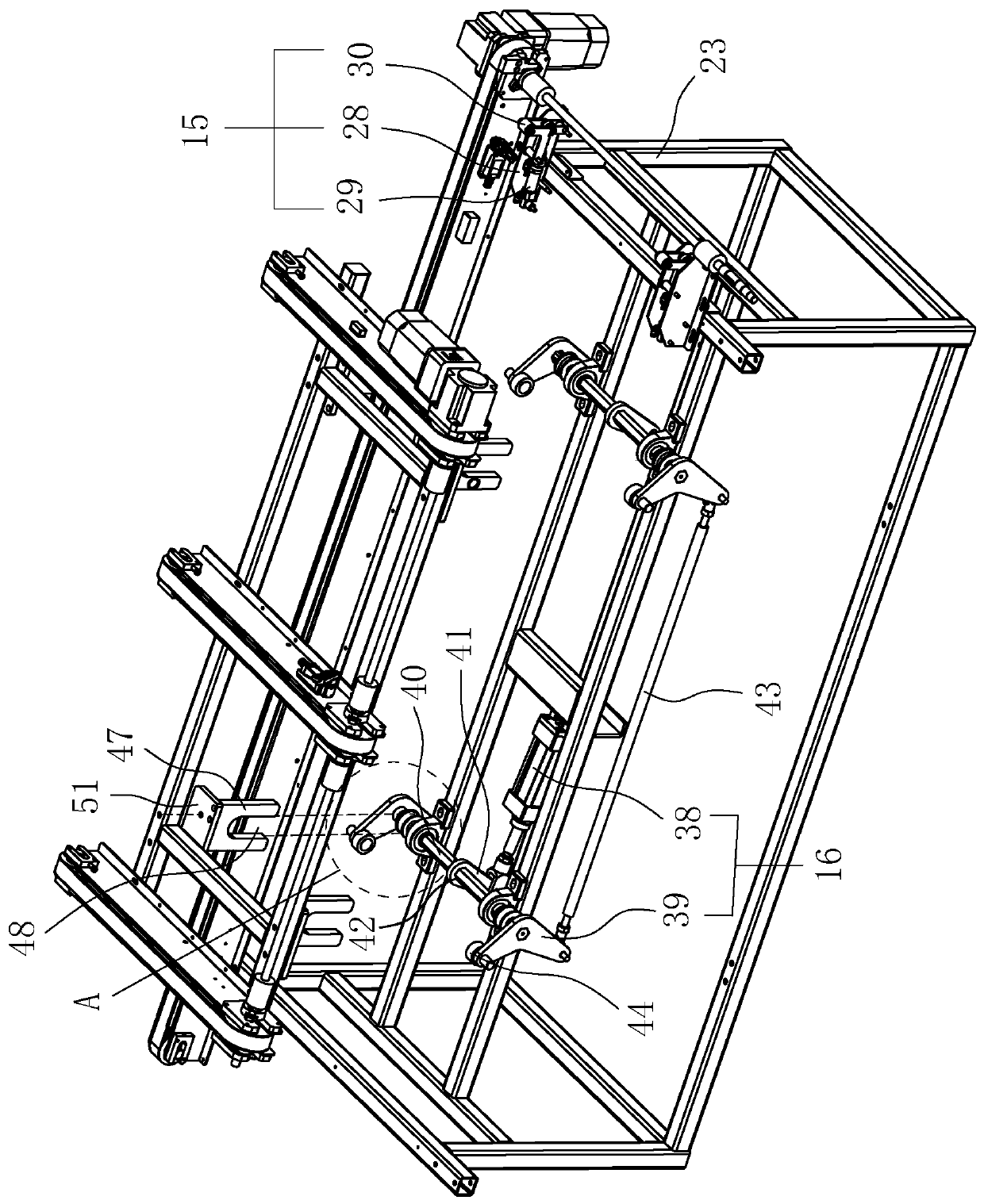

[0053] refer to figure 2 and image 3 , the glass transmission mechanism 8 includes an input assembly 14 and a limit assembly 15; the input assembly 14 is used to transport the substrate glass 6 into the frame 3; the limit assembly 15 is used to limit the position of the substrate glass 6, so that the substrate glass 6 can be more Accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com