Tenacity excellent high intensity thick steel plate for high heat energy input welding heat influenced part

A thick steel plate, high tension technology, applied in the field of high tension thick steel plate for welding, can solve the problems of limited HAZ toughness, difficult to achieve microstructure, disappearance of TiN particles, etc., to achieve superior HAZ toughness and promote the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

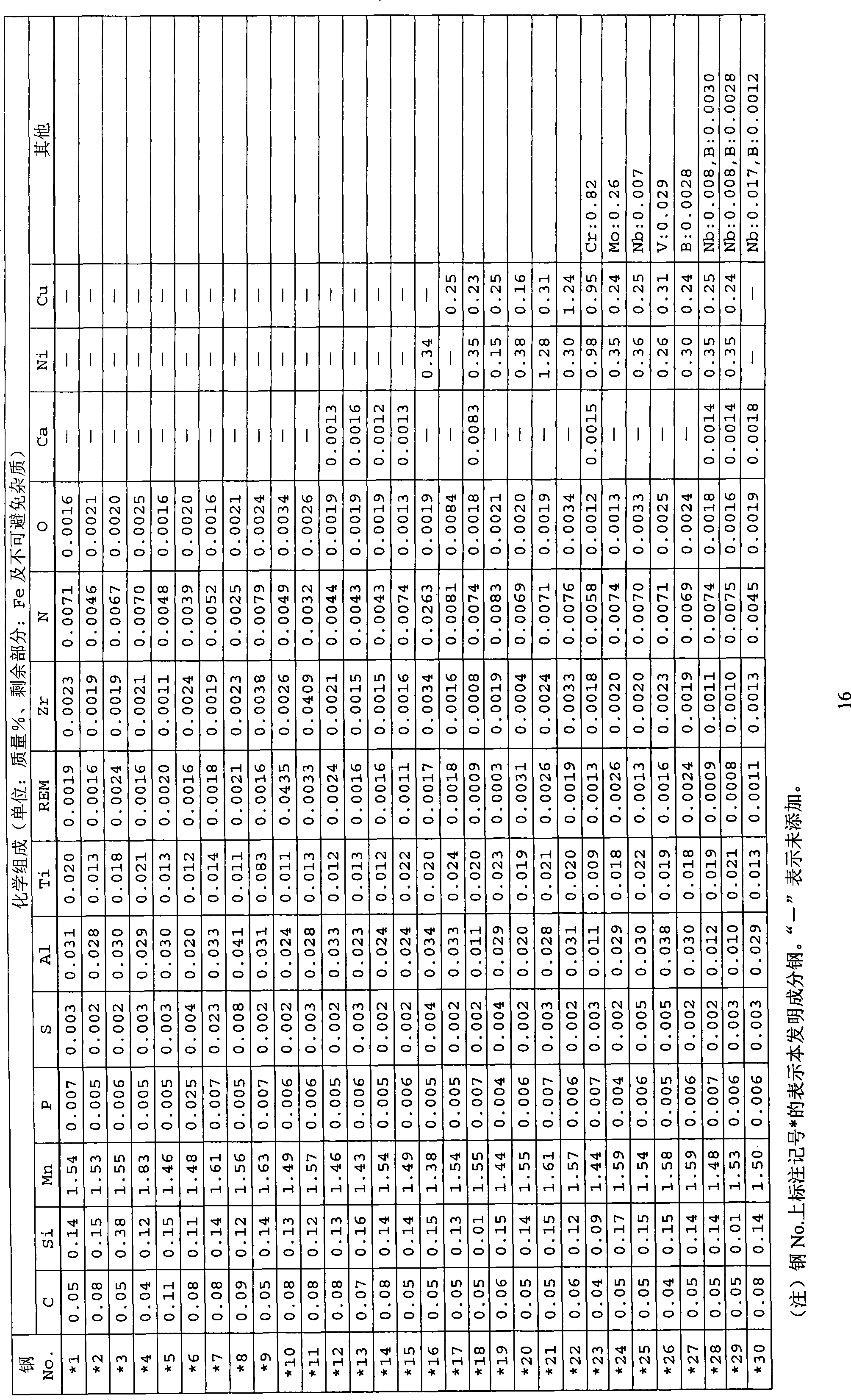

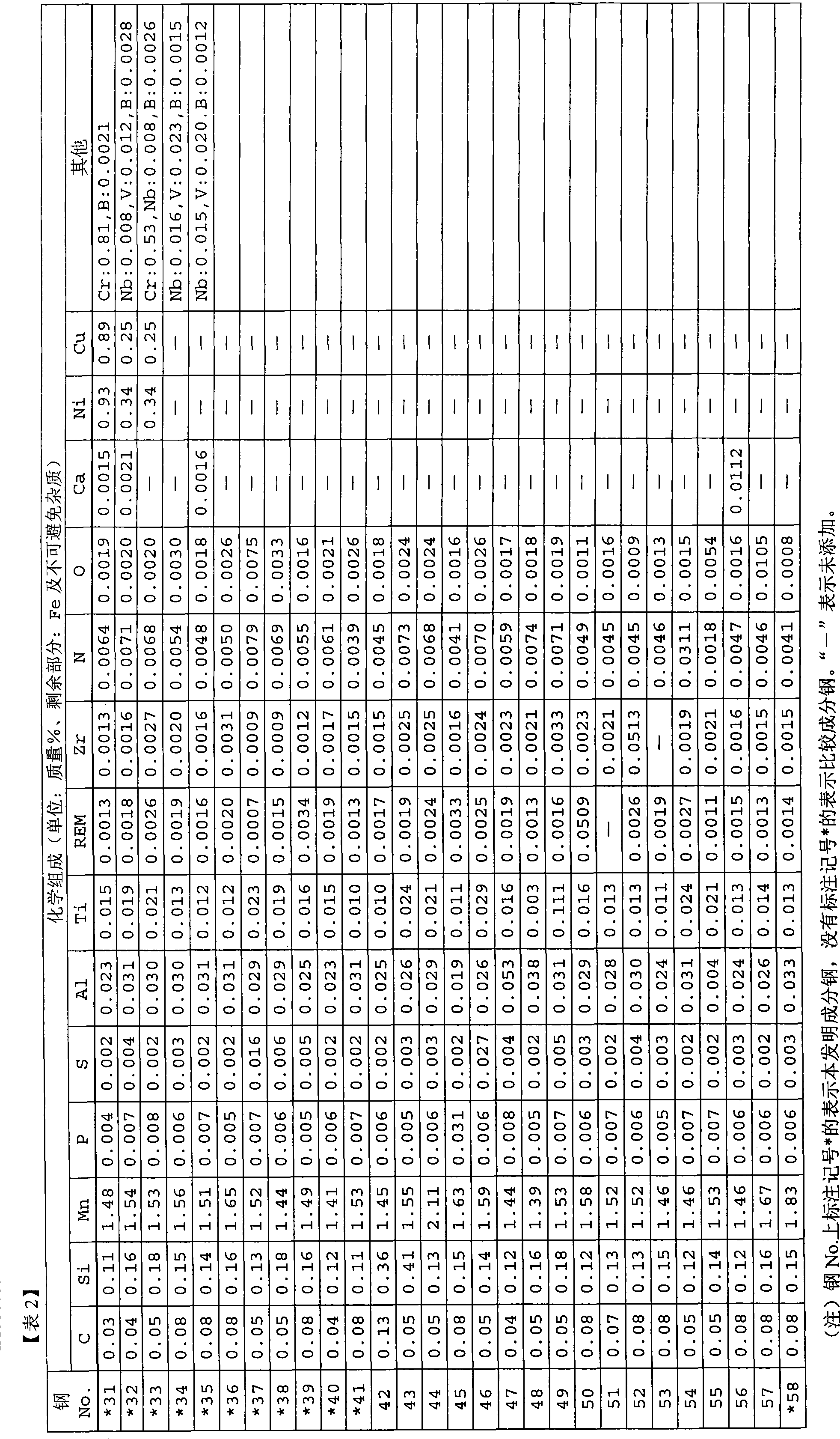

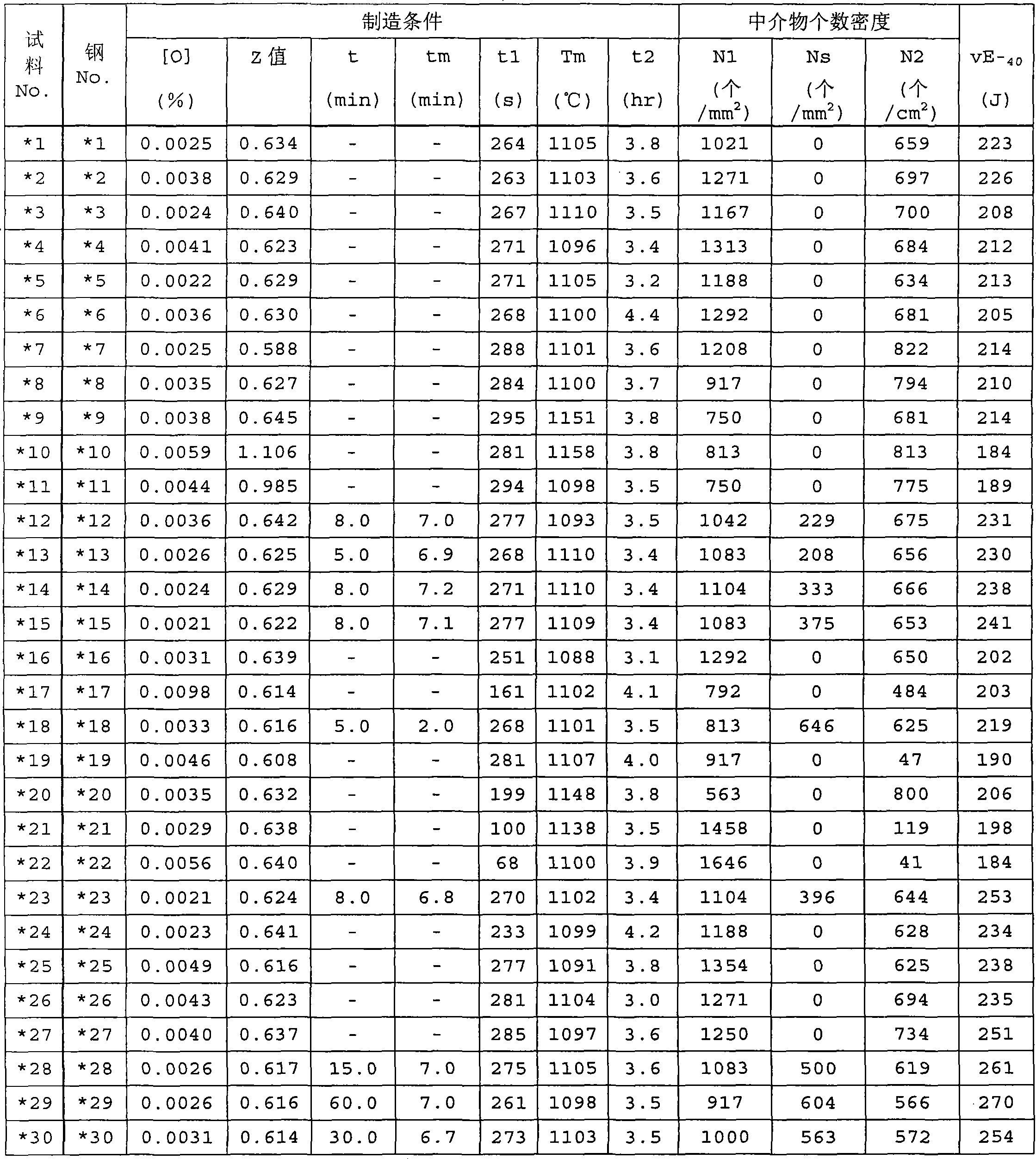

[0045] In the following, the composition and size of the oxysulfides that contribute to the promotion of the intragranular α transformation in accordance with the size and distribution density of the oxides in the steel that contribute to the suppression of the coarsening of the γ grains for the high-tensile steel plate for welding of the present invention As well as the distribution density, and the order of steel composition will be described.

[0046] Generally speaking, in order to suppress the coarsening of γ grains, it is effective to disperse relatively fine intermediary particles at a high density, but as the particle size becomes larger, the coarsening of γ grains cannot be sufficiently suppressed. Therefore, the present inventors, after experimentally studying the particle size of the intermediary that can effectively suppress the coarsening of γ grains, found that by dispersing small oxides smaller than 2 μm in terms of equivalent circle diameter to 500 particles / mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com