High sound intensity ultrasonic processing apparatus for metal and alloy solidification and processing method thereof

An ultrasonic treatment and high-sound technology, applied in the field of high-sound-intensity ultrasonic treatment devices, can solve problems such as poor ultrasonic treatment effect, resonance frequency drift, impedance and frequency mismatch, achieve degassing and component homogenization, and solve frequency drop Drift, to achieve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

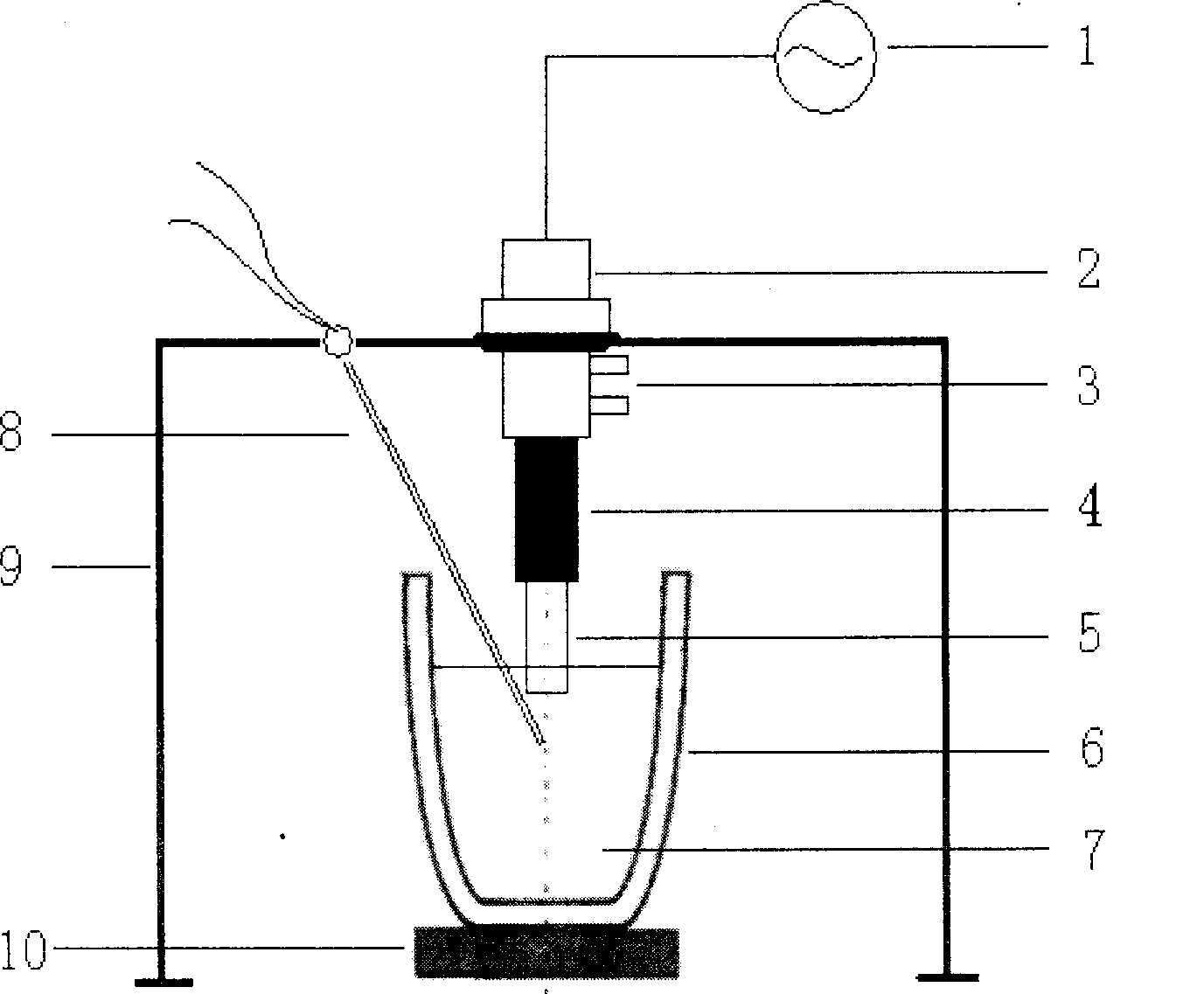

[0032] (Embodiment 1) When directly used in the solidification situation of metal and alloy melt sand molds, the curved coupling head 5 is directly inserted at the pouring riser, and a coupling head 5 is placed at a pouring riser, and the inside of the coupling head is a solid structure that is Yes, as attached figure 1 As shown, the position of the container 1 at this time is equivalent to the sand mold.

Embodiment 2

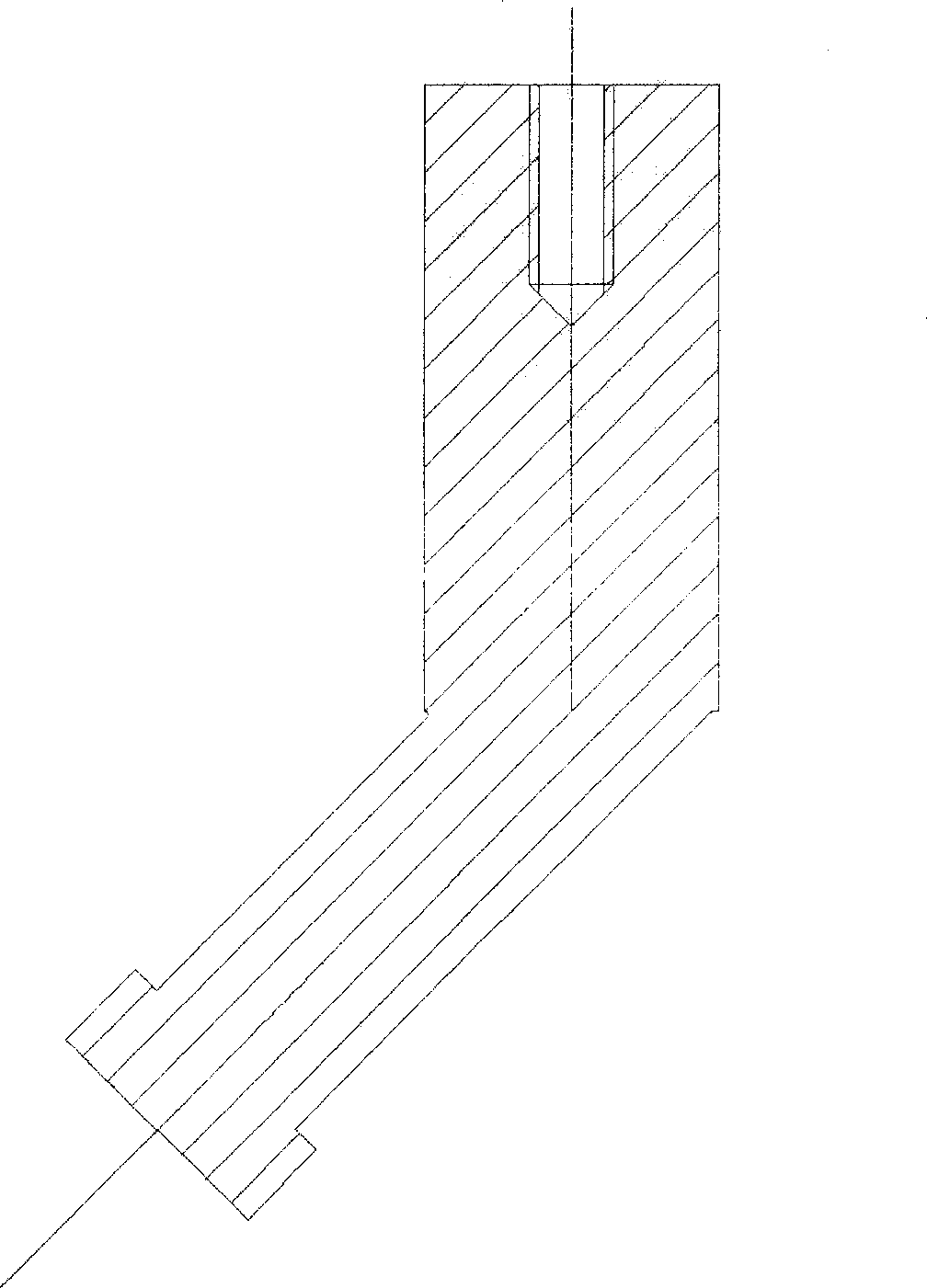

[0033] (Embodiment 2) When being directly used for semi-continuous casting of metal and alloy melts, its number of couplings varies according to the size of the crystallizer; when it is a circular crystallizer and the diameter is less than 300mm, a coupling head can be used; when the diameter When the diameter is greater than 300mm but less than 1200mm, 2 to 4 coupling heads can be used, and the coupling heads can be evenly distributed on the cross-section; if the diameter increases further, the number of coupling heads can be appropriately increased according to the actual situation; when it is made of metal and alloy For ingots or flat ingots, if the cross-sectional length dimension is between 300 and 500 mm, a curved coupling head should be selected.

Embodiment 3

[0034] (Embodiment 3) When it is directly used in continuous casting and rolling of metals and alloys, the number of coupling heads can be determined according to the size of the front box and the size of the rolls. Generally, 1 to 3 curved coupling heads are arranged in the front box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com