Torsion amplifier

An amplifier and torque technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of not improving energy utilization rate, unable to improve driving mileage, etc., achieving simple structure and reducing matching power , the effect of improving driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

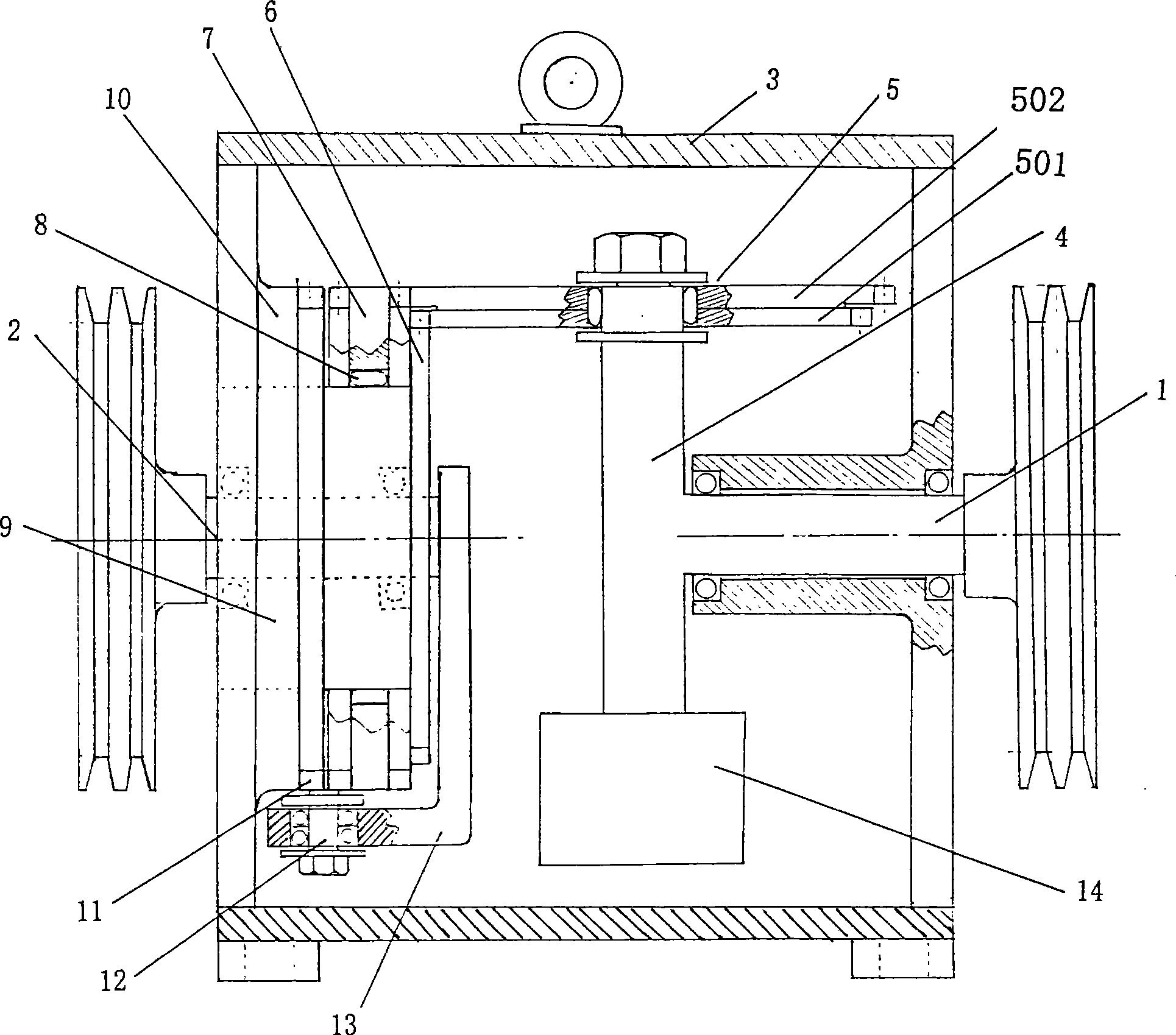

[0027] Such as figure 1 shown.

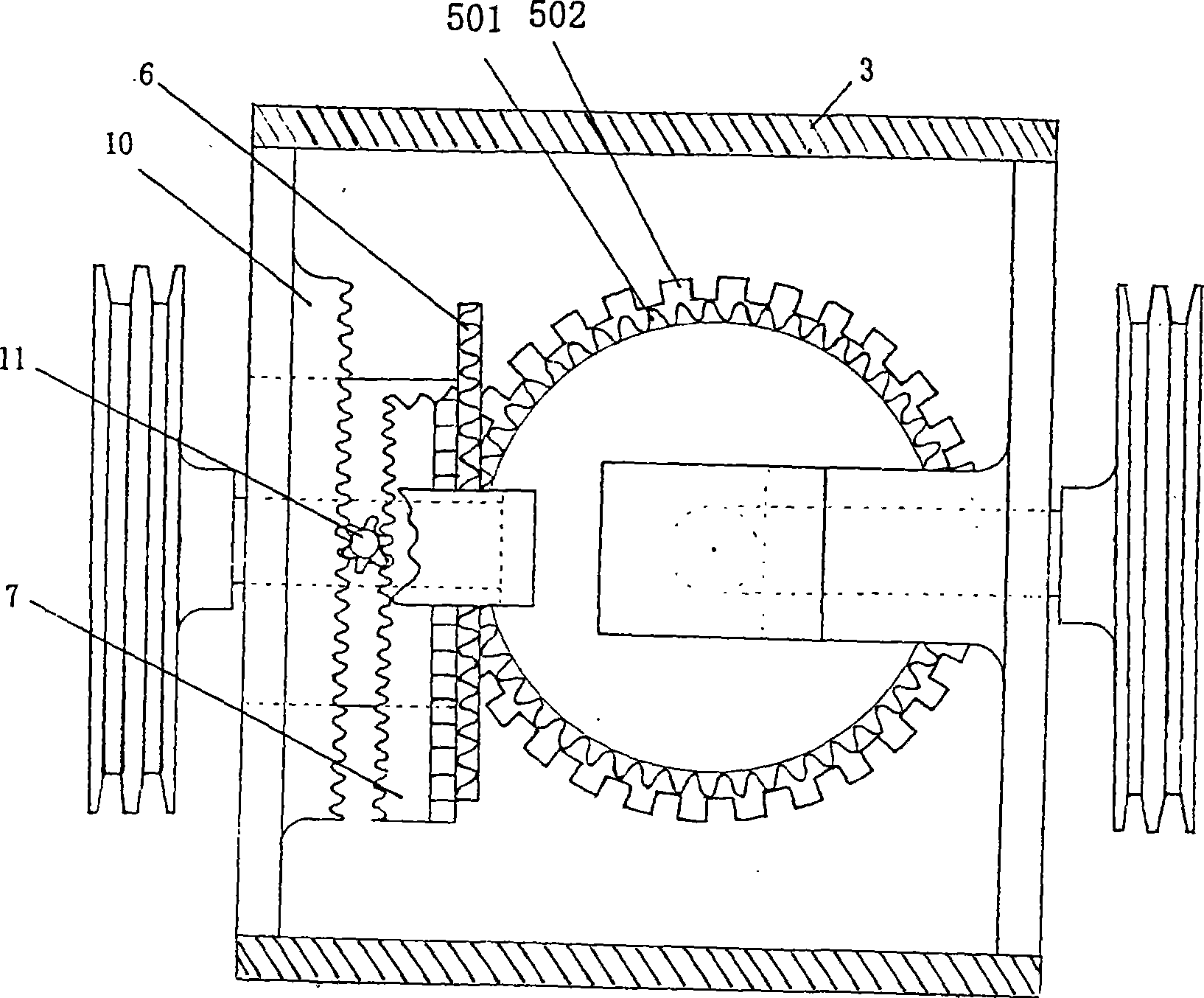

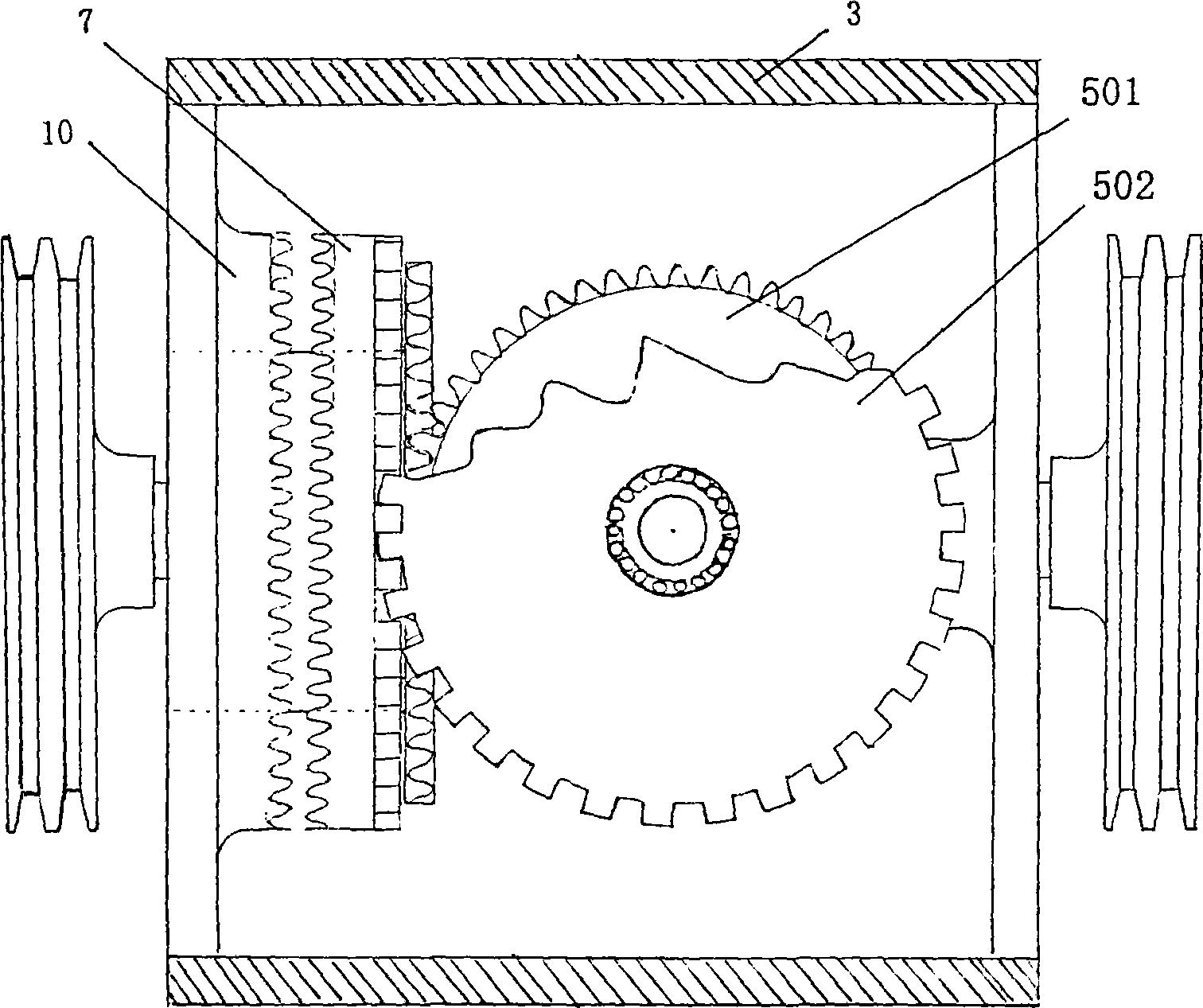

[0028] A kind of torque amplifier, it comprises input shaft 1, output shaft 2, frame 3, as figure 1 , one end of the input shaft 1 located in the frame 3 is vertically connected with a transmission shaft 4, a double gear 5 is installed on one end of the transmission shaft 4, a balance weight 14 is installed on the other end, and the pinion in the double gear 5 501 meshes with the small sun gear 6 fixed in the frame 3 on one side of the output shaft 2, and the large gear 502 in the double gear 5 meshes with a gear in the double row gear 7, as image 3 As shown, the double row gear 7 is installed on the fixed shaft 9 through the bearing 8, and one end of the fixed shaft 9 is fixedly connected with the frame 3, and the aforementioned small sun gear 6 is fixed on the fixed shaft 9, and is close to the A large sun gear 10 with the same outer diameter as the double row gear 7 is fixedly installed on one side of the output shaft 2, and a large sun g...

Embodiment 2

[0033] As shown in Figure 4 and 5.

[0034] A kind of torque amplifier, it comprises input shaft 1, output shaft 2, frame 3, input shaft 1 is positioned at one end in frame 3 and is vertically connected with drive shaft 4, and bevel gear 15 and bevel gear 15 and There is a dowel bar 16 with a one-way rotation mechanism, and a balance weight 14 is installed on the other end (the same bevel gear and a dowel bar can also be installed). One end of the dowel bar 16 is movably inserted on the force plate 17, One end of the force plate 17 is fixed on the output shaft 2; the sun gear 18 which is also a bevel gear meshed with the bevel gear 15 is fixedly installed in the frame 3 positioned at one side of the output shaft 2 . As shown in Figure 4. The one-way rotation mechanism described herein can be a one-way bearing, which is installed between the dowel rod 16 and the transmission shaft 4; Figure 5 shown in the mechanism to be implemented, Figure 5 The one-way rotation mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com