Low-pollution concentrating heat storage cremating apparatus

A low-pollution, heat storage technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as fines, high VOC concentration in exhaust gas, and failure to pass environmental air pollution standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

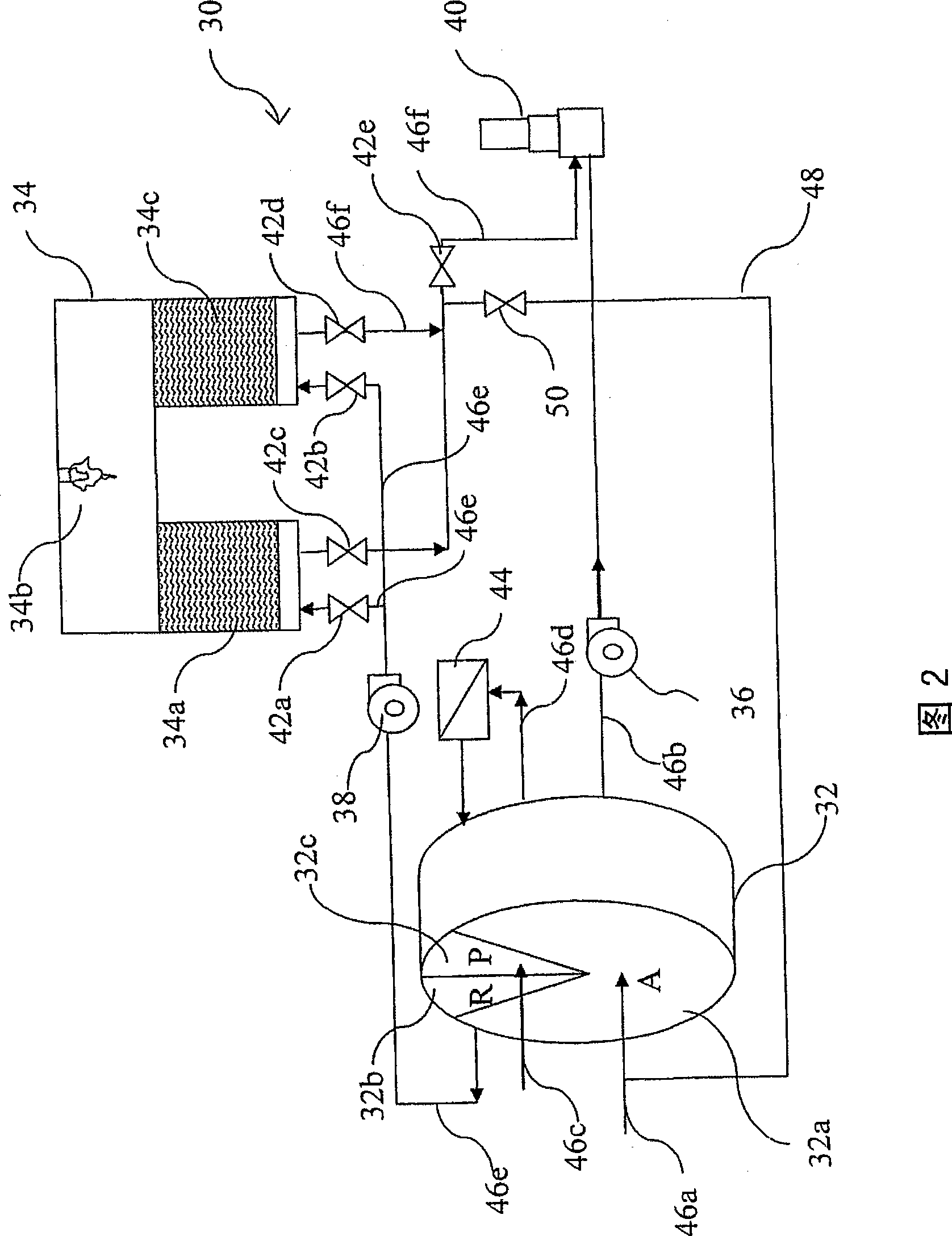

[0043] Fig. 2 is a schematic structural view of the present invention, as shown in the figure, the concentrated heat storage incinerator 30 mainly includes a zeolite runner 32, a regenerative incinerator 34, a pipeline group and a recovery pipeline group, and the zeolite runner 32 has adsorption zone 32a, desorption zone 32b and cooling zone 32c, while the regenerative incinerator 34 has a first regenerator 34a, a heating chamber 34b and a second regenerator 32c, and the pipeline group includes a pipe fitting group and a valve fitting group, wherein The pipe set includes a first pipe 46a, a second pipe 46b, a third pipe 46c, a fourth pipe 46d, a fifth pipe 46e and a sixth pipe 46f, and the valve set includes a first valve 42a, a second valve 42b, a The three valve parts 42c, the fourth valve part 42d and the fifth valve part 42e, the recycling pipeline set includes a recycling pipe part 48 and a recycling valve part 50, and the valve part group and the recycling valve part 50 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com