Anti-sulphates corrosive test method and test device of cement concrete

A cement concrete and sulfate-resistant technology, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, material weighing, etc., can solve the problems of not decreasing but increasing quality, concrete damage, and high labor intensity of testers, etc. problem, to achieve the effect of accurate test results, short cycle and low test intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

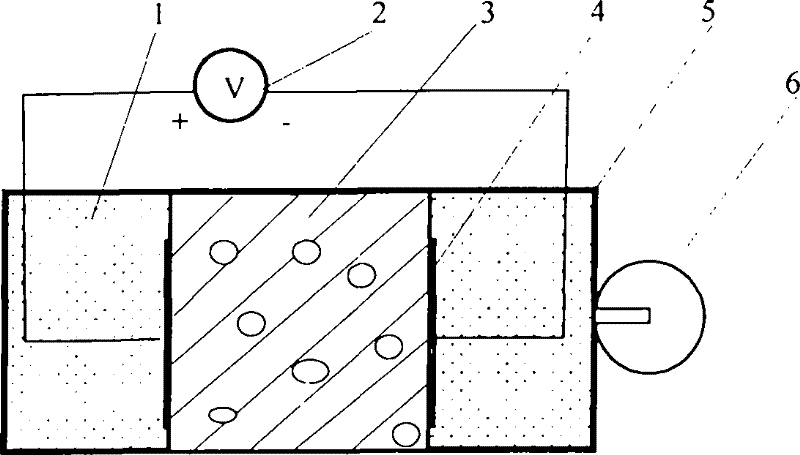

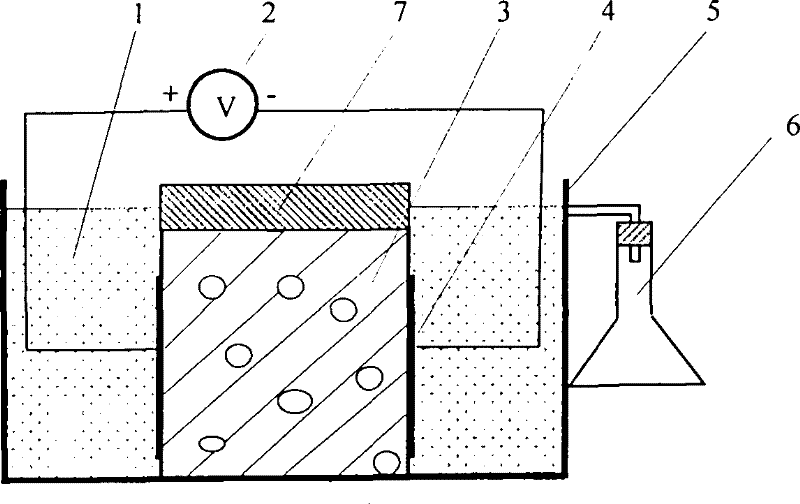

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

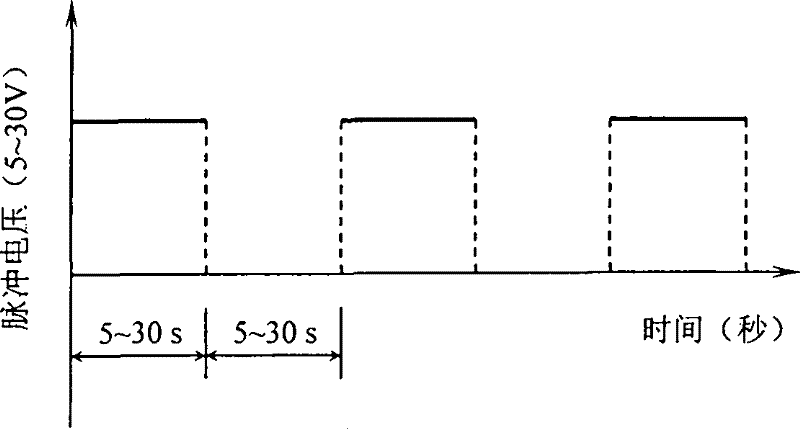

[0023] The test method for sulfate corrosion resistance of cement concrete involved in the present invention uses the principle of electroosmotic pulse technology to promote the diffusion of sulfate ions to the interior of cement concrete and promote the reaction with cement concrete hydration products, thereby achieving rapid detection of cement concrete resistance to sulfuric acid The purpose of salt corrosion ability. Specific steps are as follows:

[0024] Step 1: Prepare the cement concrete test specimen. The cement concrete test specimens used in this test can be the test samples specially prepared by the existing technology for the test, or directly take samples from the used concrete as the test specimens. The method of preparing the test sample: pour the concrete into the concrete mold, and the concrete mixture is vibrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com