Electrical fuse self test and repair

A fuse and fuse unit technology, applied in fuse testing, static memory, read-only memory, etc., can solve problems such as lack of repairability, impact on yield, and increase in manufacturing costs of integrated circuit chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following provides a detailed description of a system and method for constructing an e-fuse device capable of self-testing and repairing faulty bits.

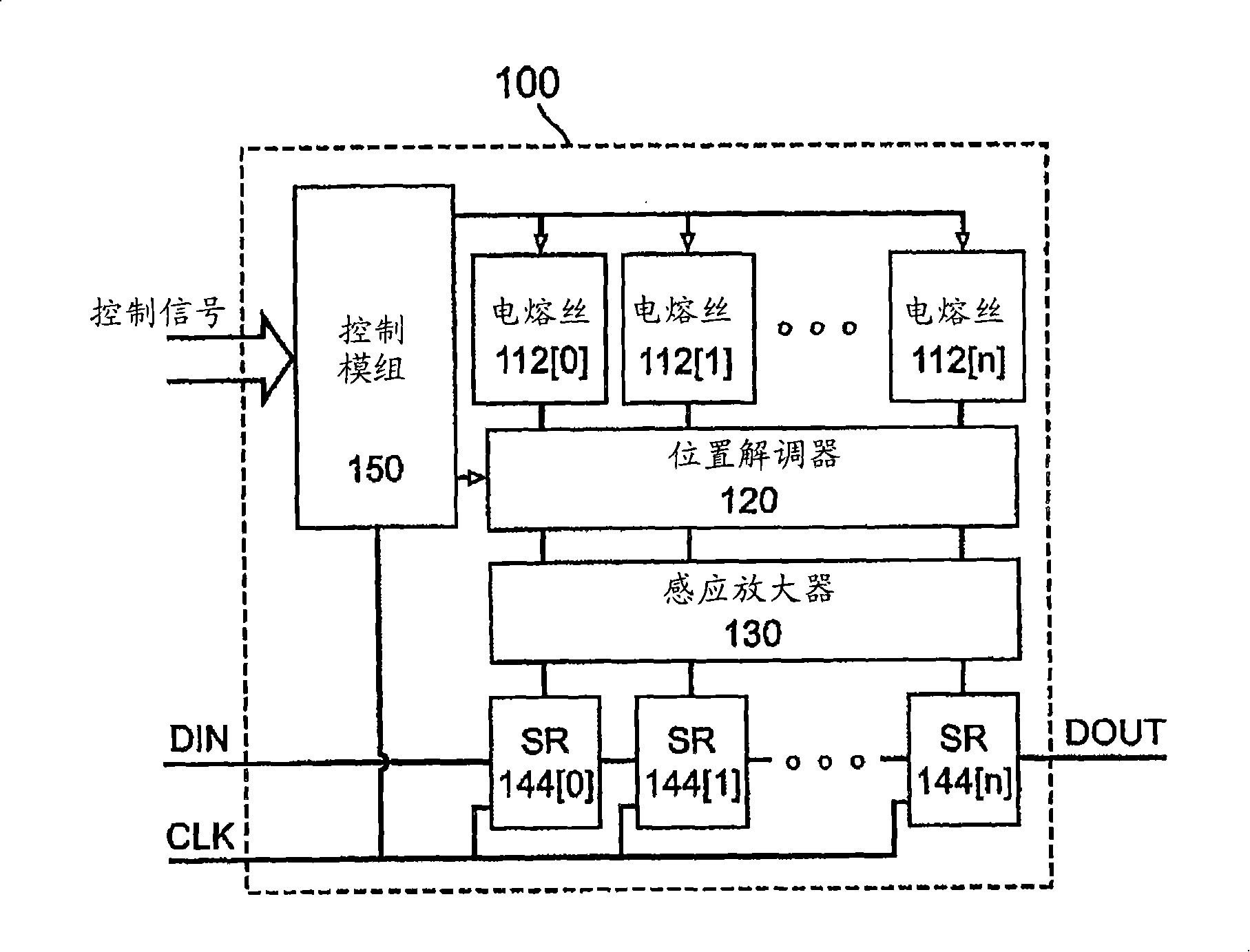

[0016] FIG. 1 shows a block diagram of a known e-fuse macro 100 . The known e-fuse macro 100 includes a plurality of e-fuses 112[0:n], a position demodulator 120, a sense amplifier module 130, and a plurality of shift registers (shift register) 144[0:n] n], and a control unit 150. The position demodulator 120 is used to select one of the plurality of electric fuses 112 [0:n] for programming or reading. Before being programmed, e-fuse 112[0:n] is low impedance. After being programmed, the impedance of the fuse rises to be visibly detected by the sense amplifier module 130 . The sense amplifier module 130 uses a known resistor (not shown) to compare the impedance of the fuse to achieve the detection of the impedance of the fuse. When the fuse is not programmed, a logic 0 is generated, and when the fuse is programmed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com