Machine for threading tube body

A wire turning machine and tube body technology, applied in turning equipment, turning equipment, metal processing machinery parts, etc., can solve the problems of small quantity, difficult assembly and maintenance, poor geometric accuracy of machine tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

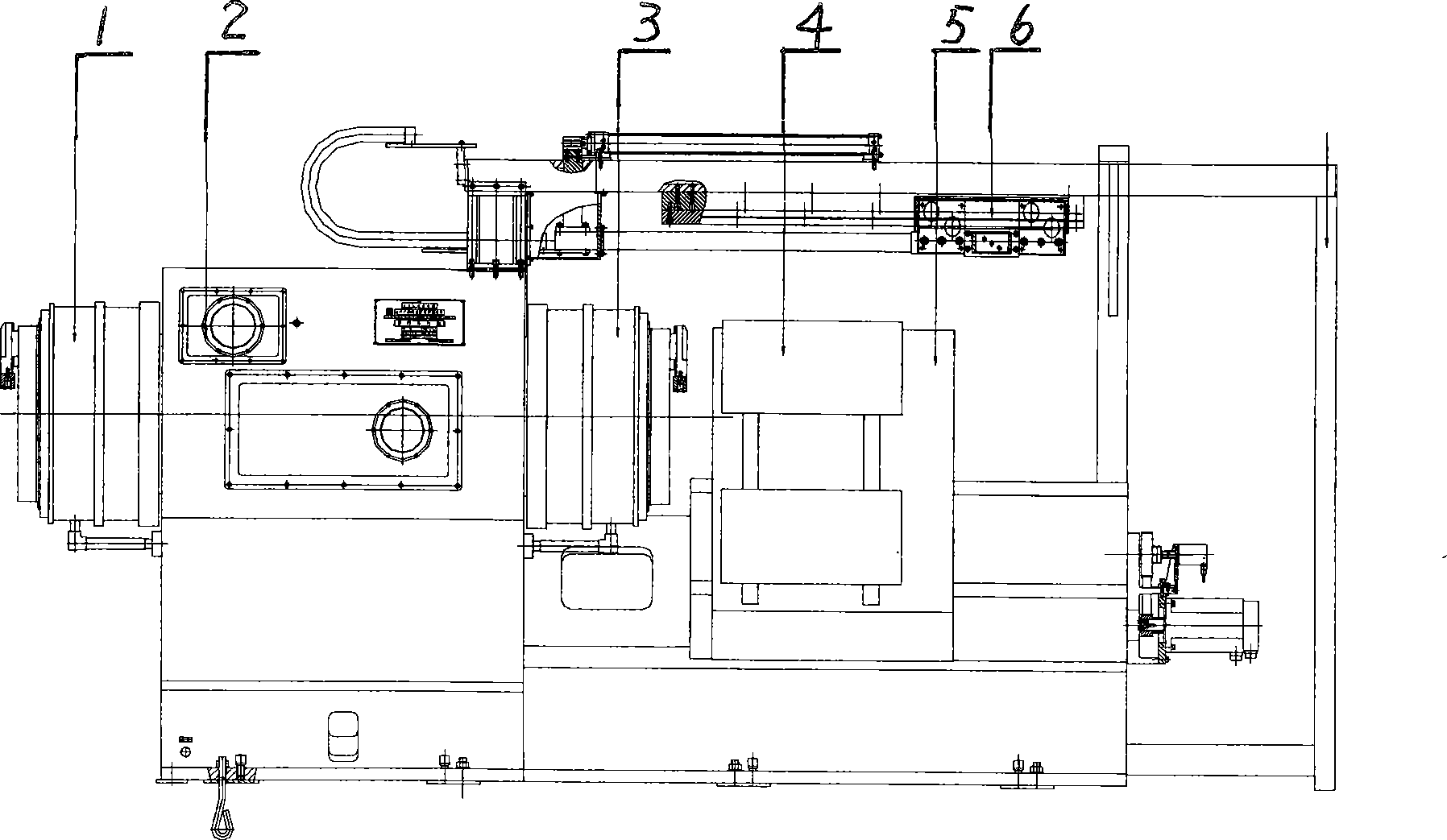

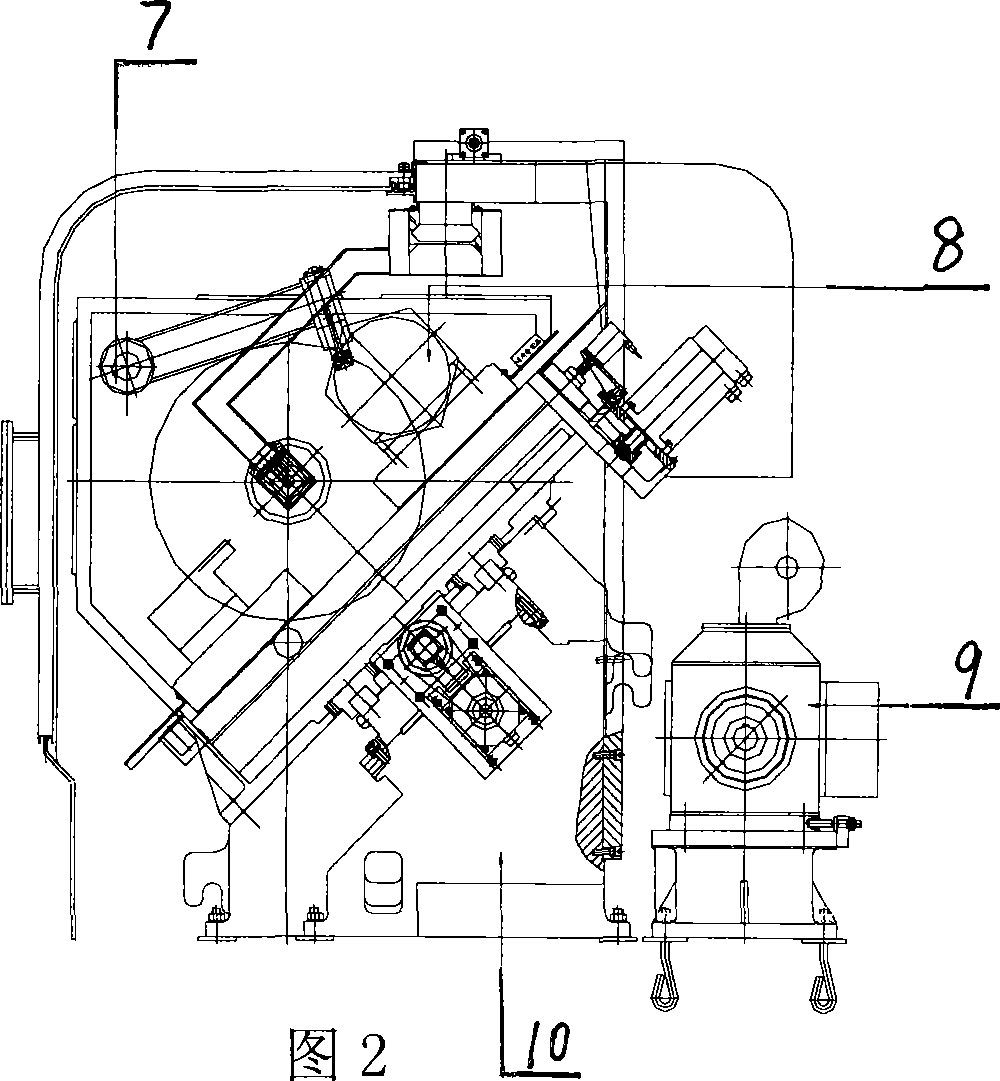

[0010] Referring to the accompanying drawings, the pipe body threading machine, the whole device consists of a rear chuck 1, a spindle box 2, a front chuck 3, a transverse slide 4, a longitudinal slide 5, a tube expander 6, a tube retainer 7, a cutter 8, and a motor 9 1. The bed 10 is composed of a headstock 2 installed on the upper left part of the bed 10. The headstock 2 is installed on the joint surface of the left part of the bed 10 inclined at 45°. The gear rotates the motor 9 of the main shaft. The front chuck 3 and the rear chuck 1 are respectively installed at the two ends of the main shaft in the headstock 2. The tube expander 6 is installed on the beam of the headstock 2. A longitudinal slide 5 for longitudinal movement, two horizontal slides 4 are installed on the two guide rails above the longitudinal slide 5, knives 8 are respectively installed on the two horizontal slides 4, and the pipe stopper 7 for the axial positioning device of the pipe is installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com