Integral binding type bundling machine

A binding and wrapping machine technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as complex procedures, hidden safety hazards, slag inclusions, and pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

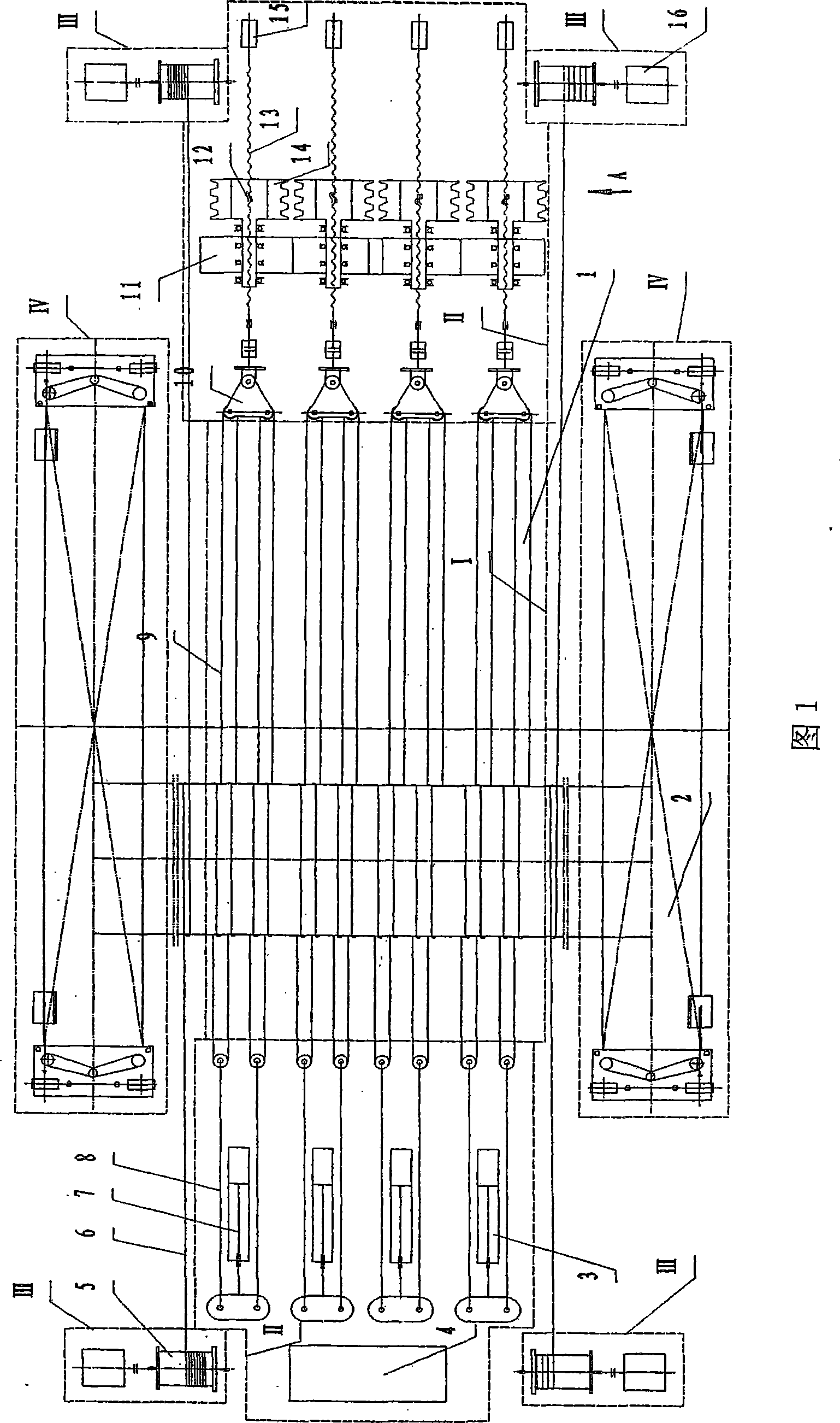

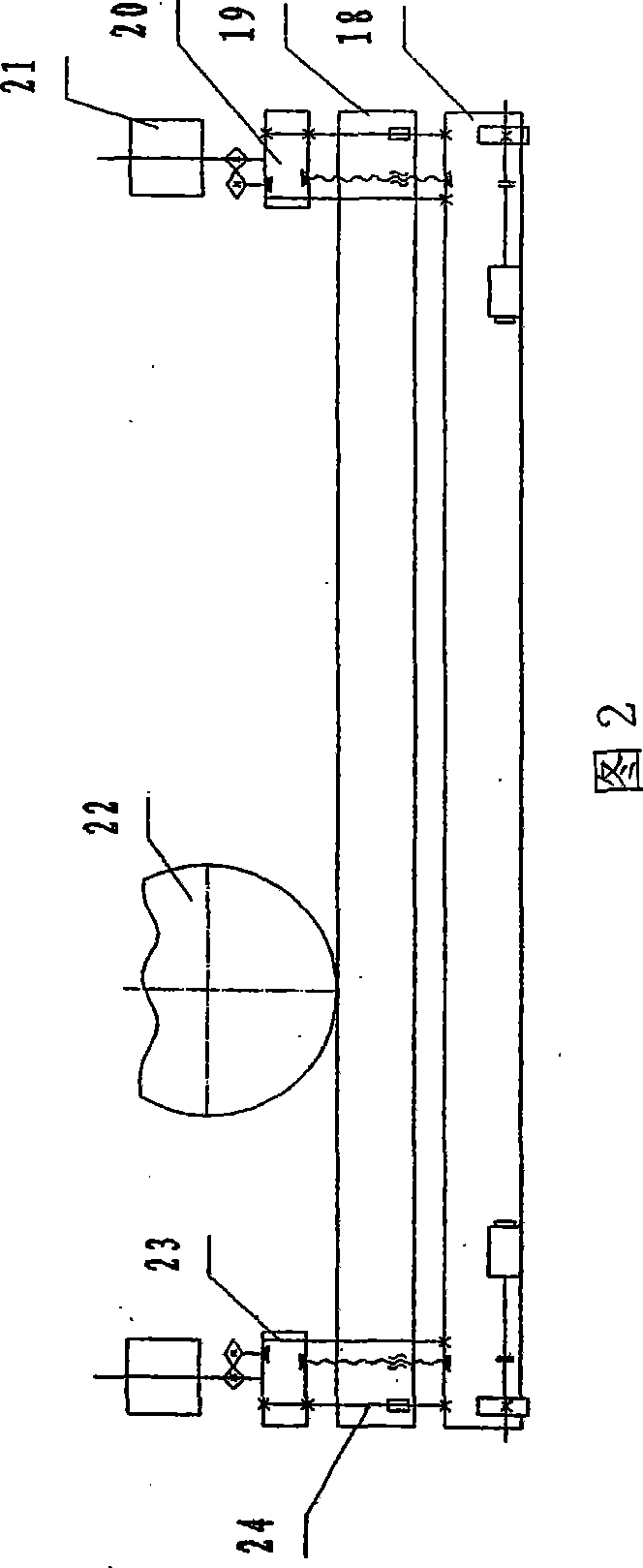

[0020] Fig. 1 shows the main body structure of the present invention, the integral binding type wrapping machine of the present invention is by wrapping workbench I, is positioned at wrapping workbench I top and is used for eliminating the wire rope tie-up mechanism II of laminate gap, makes workpiece work in wrapping The wire rope traction mechanism III for reciprocating rolling on the table and two trolleys IV located on both sides of the wrapping table can vertically lift the workpiece and move along the axial direction of the workpiece.

[0021] The binding workbench I is a rectangular platform 1 built by concrete, which is used to support the workpiece 22 and fix the wire rope binding mechanism II.

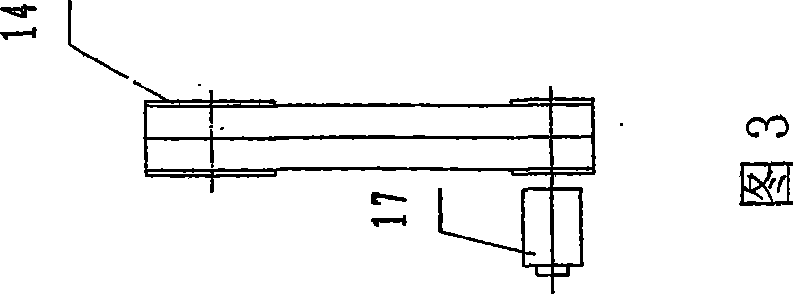

[0022] The wire rope tightening mechanism II is located above the binding workbench I, including the piston hydraulic cylinder 3 for pulling the wire rope, the hydraulic system 4 providing power for the hydraulic cylinder 3, the wire rope group and the pretensioning device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com